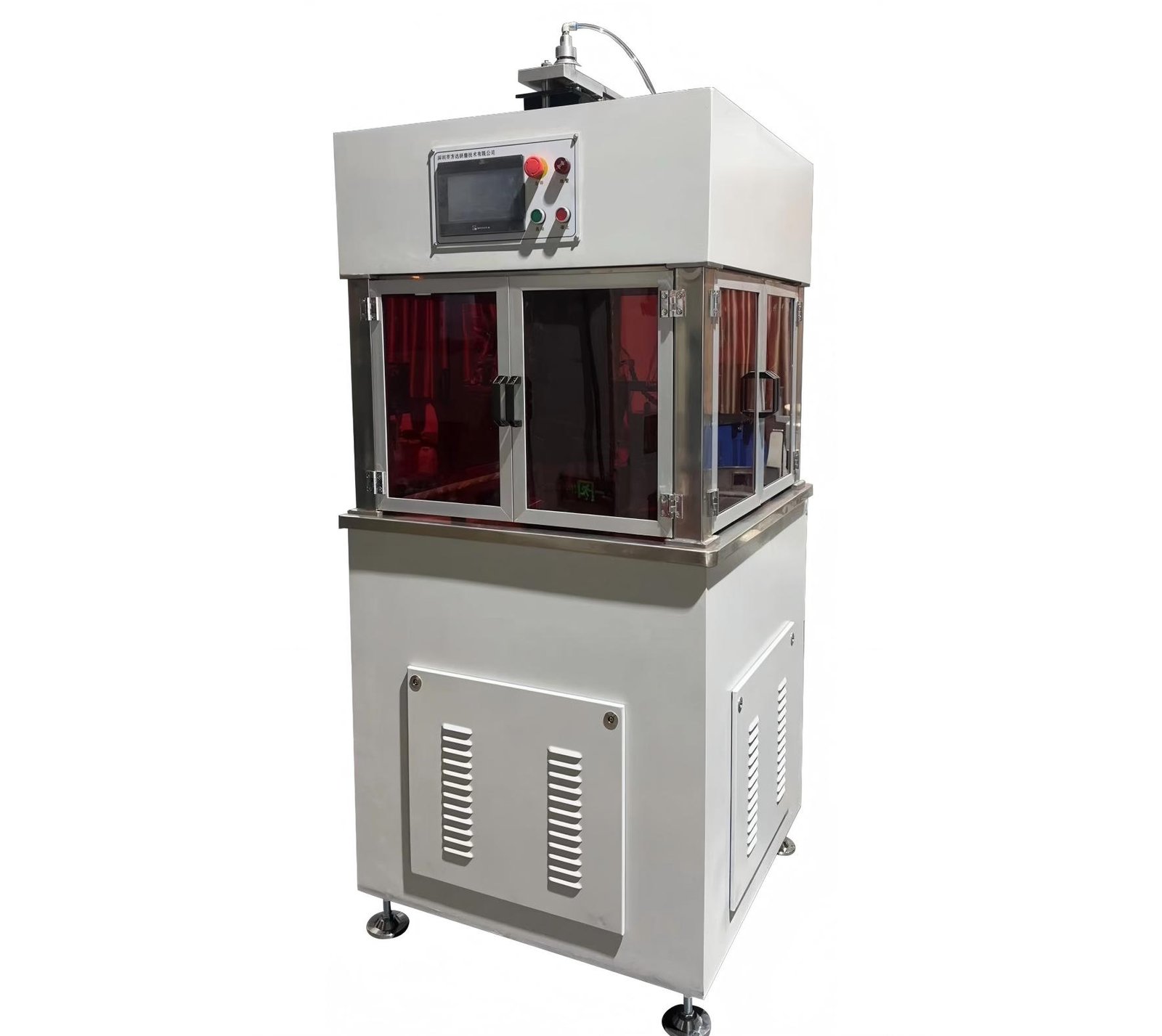

This equipment is mainly used for precision grinding of semiconductor materials such as sapphire, silicon wafers, ceramics, lithium tantalate, and gallium arsenide.

| Grinding Disk Specification | 460x160x12mm |

| Main Motor Power | 2.2KW/380V |

| Pressure Plate Motor Power | 0.2KW/380V x 2 |

| Grinding Disk Speed | 10-80rpm |

| Trimming Machine Power | 0.2KW/380V |

| Number of Workstations | 2 |

| Equipment Pressure | 10-60KG/workstation |

| Pressure Plate Speed | 5-60rpm (max) |

| Equipment Weight | 1350kg |

| Dimensions | 1200x1500x1850mm |

Rm3A08 (4th Floor) Block D, Huashengtai Technology Park, No.36 Hangkong Road, Baoan District, Shenzhen City, China

© 2025 All Rights Reserved.