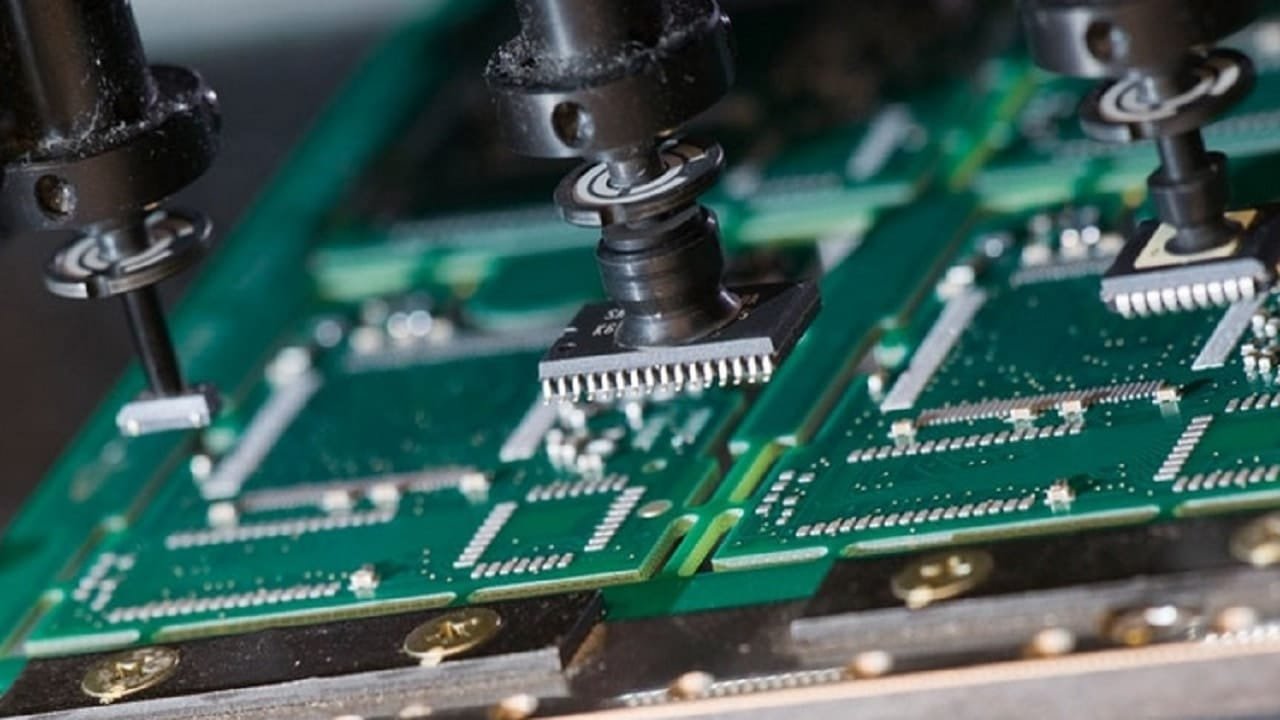

Ensuring Accuracy in SMT Machines

SMT machines utilize various methods to ensure the accurate placement of electronic components. The key methods include:

1. Visual Positioning System

Upper CCD “Coarse Positioning”: The upper CCD (Charge-Coupled Device) camera performs initial positioning to obtain approximate location information of the components. The camera captures the component image, and the system uses shape matching and pixel area conditions to determine the component’s position and orientation. Based on this preliminary positioning result, the robotic arm adjusts to the appropriate position to grasp the component.

Lower CCD “Fine Positioning”: The lower CCD camera conducts secondary positioning to ensure precise location of the component on the PCB. Once the camera captures the actual position of the component on the PCB, the system calculates the deviation and adjusts the position and angle of the robotic arm to ensure accurate placement.

2. Precision Motion Control System

SMT machines are equipped with high-precision XY tables that can control the position of PCBs accurately. Stepper motors facilitate precise displacement control, with each electrical pulse causing the motor to rotate a specific angle for accurate movement. Driver chips, such as ULN2003, convert the microcontroller’s control signals into actual motor movements by providing sufficient drive current.

3. Data Storage and Processing

Database Linked List Storage: Programming languages leverage database linked list storage technology to save the pose matrix information of components. Information can be quickly accessed using pointer techniques when needed, ensuring the robotic arm executes placement tasks accurately.

Quick Sort Algorithm: This algorithm is used to reorder pose data, optimizing the placement sequence and reducing unnecessary movement and adjustment time.

4. Nozzle Design and Adjustment

Choosing the appropriate nozzle based on component type and size ensures stability and accuracy during pickup. Nozzle height is adjusted at the pickup position to align with the feeder, preventing pickup failures. Centering the nozzle with the feeder reduces errors during component retrieval.

5. Feeder Management

Feeder Inspection: Inspect feeders for wear and structural deformities before installation. Severe wear of the feeder claw can prevent the tape from peeling off correctly, impacting the nozzle’s component pickup. Additionally, components may deform over time or due to improper operation, affecting feeder stability. Regular checks and maintenance can help mitigate these issues.

6. Programming and Software Support

Assembly Expert Software: This software generates vector electronic inspection diagrams that clearly indicate which components need to be placed, which do not, and their orientations. The inspection diagram streamlines the search for positions, reducing human errors while allowing images and annotations for an accurate and quick SMT first inspection.

7. Human-Machine Interaction

Key operations are facilitated through button circuits for human-machine interaction, including timing and quantity settings for material feed start and end. Digital displays show timing and material levels, allowing operators to monitor the material feeding process visually.

8. Real-Time Monitoring and Feedback

Alarm System: The system sounds alarms and displays visual signals when reloading is complete or faults occur, alerting operators to address issues promptly.

LED Indicators: LED lights display current material levels for operators to easily track the progress of material feeding.

9. Environmental Control

Temperature and Humidity: The temperature in SMT workshops is generally maintained at 23±5°C, with a recommended range of 23±2°C. Humidity is maintained between 30% and 70% RH, ideally between 40% and 60% RH. Good environmental conditions contribute to improved accuracy and reliability in component placement.

Damp Prevention: For humidity-sensitive components, measures such as using desiccants and moisture-proof bags ensure components remain dry before use.

Through a combination of these methods, SMT machines can achieve high precision and reliability in component placement, thereby enhancing overall production efficiency and product quality.