The HWF-60 series machine, the latest and most practical odd form insertion machine, easily help SMT factory realize odd form shape components insertion automation.

Independent of the number of sets of servo control system and high-precision visual capture system, complete the high and stable performance of the insertion to achieve high speed and high density of the perfect effect.

The system can be upgraded for your equipment to update and speed up the laying of a good foundation for a simple and easy-to-understand operating platform to achieve the dialogue of the human-computer interface, the combination of practical experience and scientific theories to bring you to the quality of the product and the enhancement of production efficiency.

Model | HWF-60 |

Theoretical speed | Approx. 6000 CPH |

Insertion direction | 0°-360°, 1° increment |

Insertion head | 4 |

PCB size | 50x50mm – 500x400mm |

PCB thickness | 0.59-2.36mm |

Component spec | Max height: 50mm, max weight 0.3kg |

Feeder access | 6 |

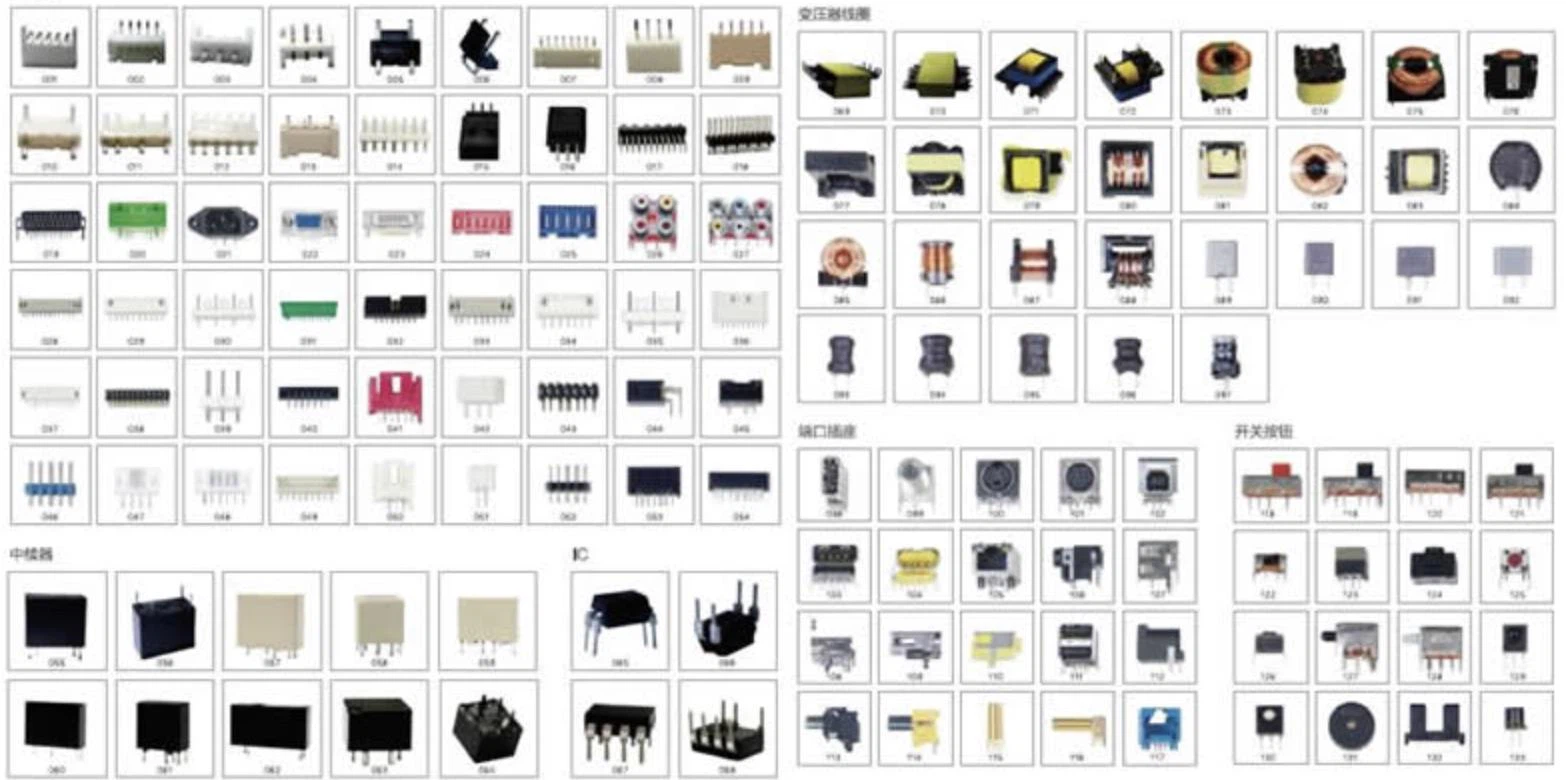

Feeder | Optional: taped feeder, tube feeder, auto pallet feeder, vibrate bowl |

Machine dimension | 1400x1500x1600mm |

Power supply | AC220V, single phase, 50/60HZ |

Air supply/ consumption | 0.6-0.8Mpa / 0.3M³ /min |

Camera 1 Hole position correction | Vision system, multi-point MARK vision |

Camera 2 | Lead tip recognition |

Drive system | AC servo motor |

Data input mode | USB port (EXCEL file) |

Rm3A08 (4th Floor) Block D, Huashengtai Technology Park, No.36 Hangkong Road, Baoan District, Shenzhen City, China

© 2026 All Rights Reserved.