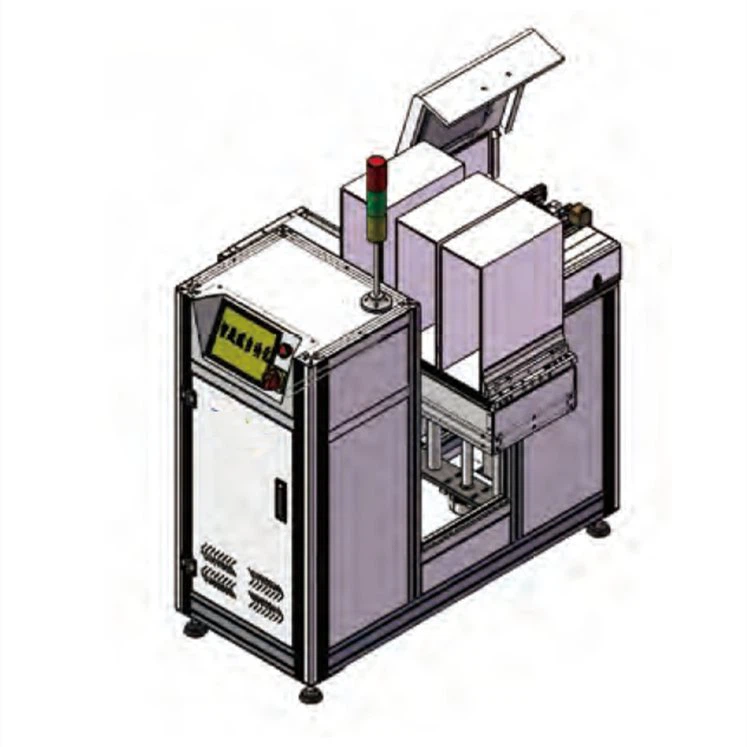

This BGA loading and unloading machine is mainly used for semiconductor packaging and testing, washing the front end of the line body, and transferring the BGA board to the following equipment through the magazine storage method, with an automatic loading/unloading function. This BGA loading and unloading equipment is a required machine for BGA board feeding operation in the semiconductor production line.

Equipped by a servo motor for lifting and translation, lifting and transfer spacing can be set arbitrarily. The BGA Loading and Unloading Machine use a stepping motor as controller and the frame change method adopts the platform multi-frame storage method, with single-frame feeding and multiple-frame simultaneous feeding functions. Mechanical clamping type bin positioning method, which can adjust different size bins arbitrarily. Equipped with standard SMEMA communication port, which can communicate with other automation equipment.

| Model | HBLD-600A M/L/LL/XL | HBUL-600A M/L/LL/XL |

|---|---|---|

| Dimension | 1175*1000*1080 | 1175*1000*1080 |

| PCB Size | 80*50-330120 | 80*50-330*120 |

| Weight | 240 (KG) | 245 (KG) |

| Rack Size | 50*80*100-300*150*400 | 50*80*100-300*150*400 |

| PCB Thickness | Min 0.2-2mm | Min 0.2-2mm |

Rm3A08 (4th Floor) Block D, Huashengtai Technology Park, No.36 Hangkong Road, Baoan District, Shenzhen City, China

© 2026 All Rights Reserved.