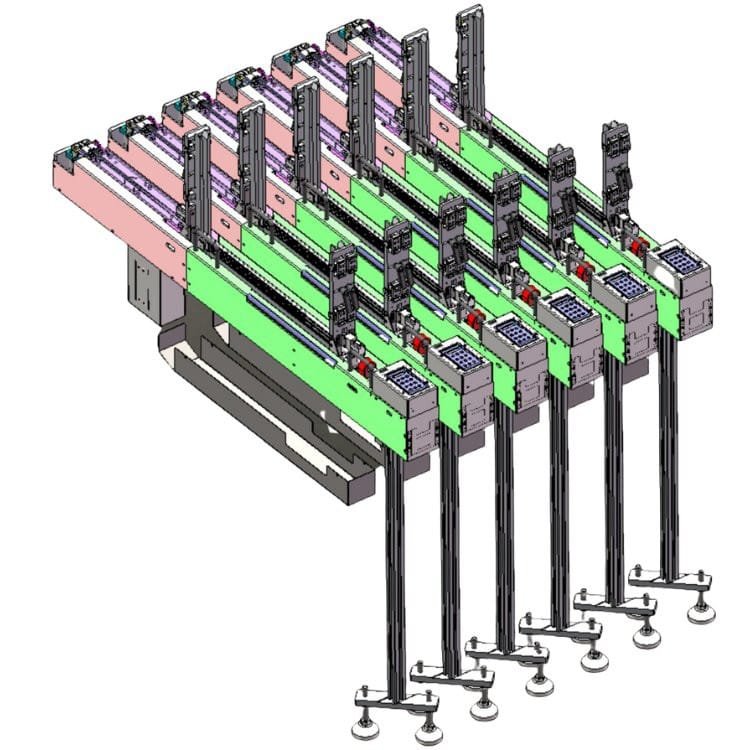

The Horizontal Stacked Tube Feeders (HTFs) are high-volume, high-speed component feeding systems that can feed a variety of components, ranging from SMT devices to odd-form components. They feed parts directly from the shipping magazines/ tubes or in-process handling tubes. The tubes are stacked in the feeder horizontally. A pusher tape pushes the components out of the bottom tube and to the pickup point. HTFs automatically eject the empty tube and index the next tube into the feeding position.

This stacked tube feeder is used for the SMT mounter machine, feeding tubes of components such as capacitor/ safety capacitor/ IC/ Keys/ triode/ LED. Compatible with Panasonic, Juki, Fuji, ASM, Universal, Yamaha, etc., with height mechanical matching and communication to the machine.

For more customization details, message us.

Rm3A08 (4th Floor) Block D, Huashengtai Technology Park, No.36 Hangkong Road, Baoan District, Shenzhen City, China

© 2026 All Rights Reserved.