HW-A8 Full Automatic 8-Head LED Placement Machine: An Efficient Solution for SMT Production

As a professional SMT equipment manufacturer, we are proud to introduce the HW-A8 Full Automatic 8-Head LED Placement Machine, specifically designed for batch production in the LED industry. It combines cutting-edge technology with industrial-grade stability, helping customers achieve efficient, precise, and low-cost intelligent manufacturing. Below, we analyze the product competitiveness from three dimensions: core advantages, technical highlights, and market value:

1. Core Competitive Advantages

- Industry-Leading Production Efficiency

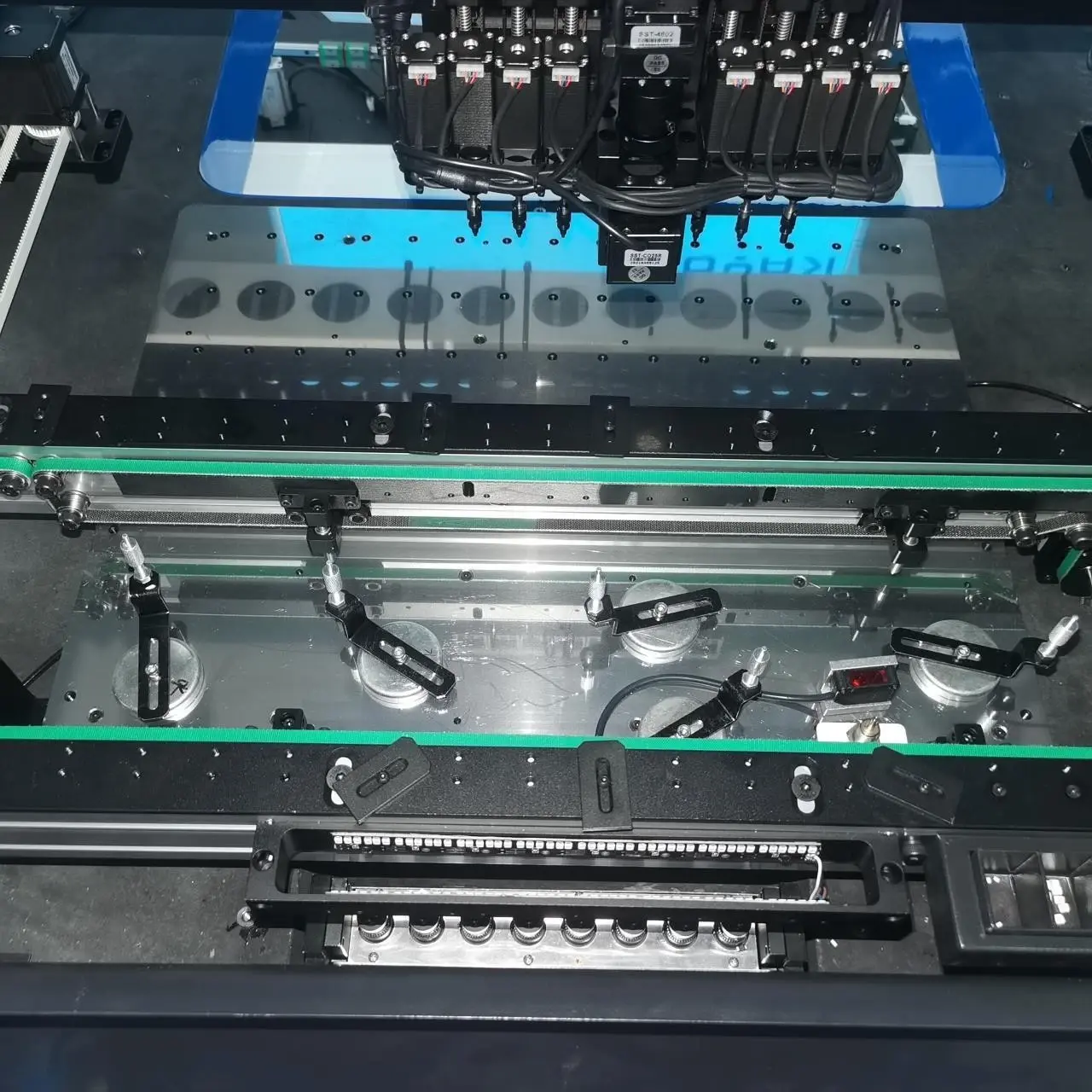

- 8 Head Parallel Placement + 8 Industrial Vision Cameras: Synchronous identification and placement, with theoretical peak production capacity reaching 40,000 CPH (components per hour), while actual stable production capacity remains at 15,000-30,000 CPH, suitable for large-scale production scenarios such as LED strip lights, bulb lights, and driver boards.

- 0-360° Rotation Placement: Supports precise positioning of components at any angle (accuracy ±0.05mm), accommodating complex PCB layout requirements.

- Industrial-Grade Stability and Long Lifespan Design

- Granite Base + 200kg Weight: Significantly reduces vibration interference, ensuring stability for continuous 7×24 hour operation.

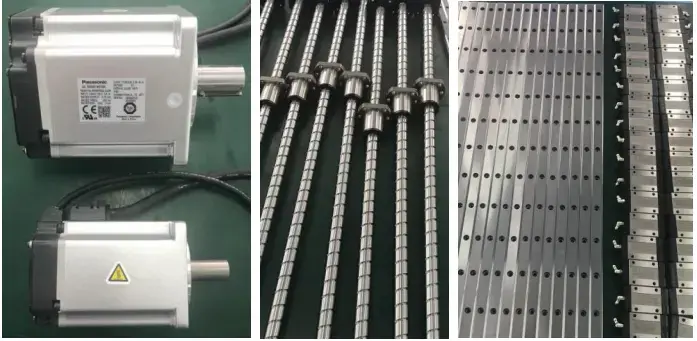

- Imported Panasonic Servo System + TBI Heavy-Duty Precision Rails: Key transmission components have a lifespan extended by 30%, reducing long-term maintenance costs.

- Flexible Expandability

- PCB Length Extendable to 1.2 Meters: Custom-designed for extra-long LED strips, compatible with standard board sizes of 600×400mm.

- 30×8mm Standard Feeders: Supports multiple tape sizes including 8/12/16/24mm, allowing for quick product type switching.

2. Technical Highlights and Parameter Analysis

| Function Module | Technical Specifications |

|---|---|

| Vision System | 8 flying cameras + reference positioning camera (accuracy < 0.05mm), optional high-precision version up to ±30μm |

| Motion Control | Panasonic servo drive, X/Y axis stroke 600mm×400mm, Z axis stroke 12mm, repeat positioning accuracy ±0.01mm |

| Compatibility | Minimum placement of 0402 package components (within 11mm), supports 3528/5050 LEDs, SOP/SOT ICs, high-power devices |

| Operating System | Windows 7 control platform, vision-guided automatic programming, user-friendly interface |

| Energy Consumption and Compatibility | 220V standard voltage supply, power 2.0kW, reduces factory circuit renovation costs |

3. 8 heads led pick and place machine Application Scenarios and Market Value

- Wide Coverage of the LED Industry Chain

- Traditional LED Products: Strip lights, bulb lights, downlights, and barrier tubing.

- High-Value Added Fields: LED display modules, copper wire light strings, and smart driver control boards.

- Reduce Overall Production Costs

- Reduce Dependence on Labor: Fully automated conveyor belt + three-level buffering system achieve unmanned assembly line operation.

- Fast Return on Investment Cycle: With a production capacity of 30,000 CPH, a single machine can achieve a daily output of 240,000 components, meeting the monthly production capacity needs of medium-sized enterprises.

- Align with Industry Trends

- Mini LED/Micro LED Compatibility: By upgrading the vision system, it can adapt to the future mounting needs of miniaturized components.

4. Partnership Value Proposition

HW-A8 focuses on “High Precision, High Efficiency, High Reliability” to provide LED manufacturers with a one-stop placement solution:

- Free Technical Adaptation: Offers PCB design optimization advice to shorten trial production cycles.

- Global Service Network: 48-hour response to after-sales needs, key components with a 5-year warranty.

Contact Us Today: Get a customized capacity plan and start a new era of efficient production!

tag:Wholesale 8 heads led pick and place machine