Vision Systems in Pick-and-Place Machines

Modern pick-and-place vision systems serve as the “eyes and brain” of electronic manufacturing equipment, combining advanced imaging hardware with intelligent software to achieve micron-level precision in component placement. This guide covers system architecture, core functions, technological evolution, and detailed model comparisons.

I. System Architecture

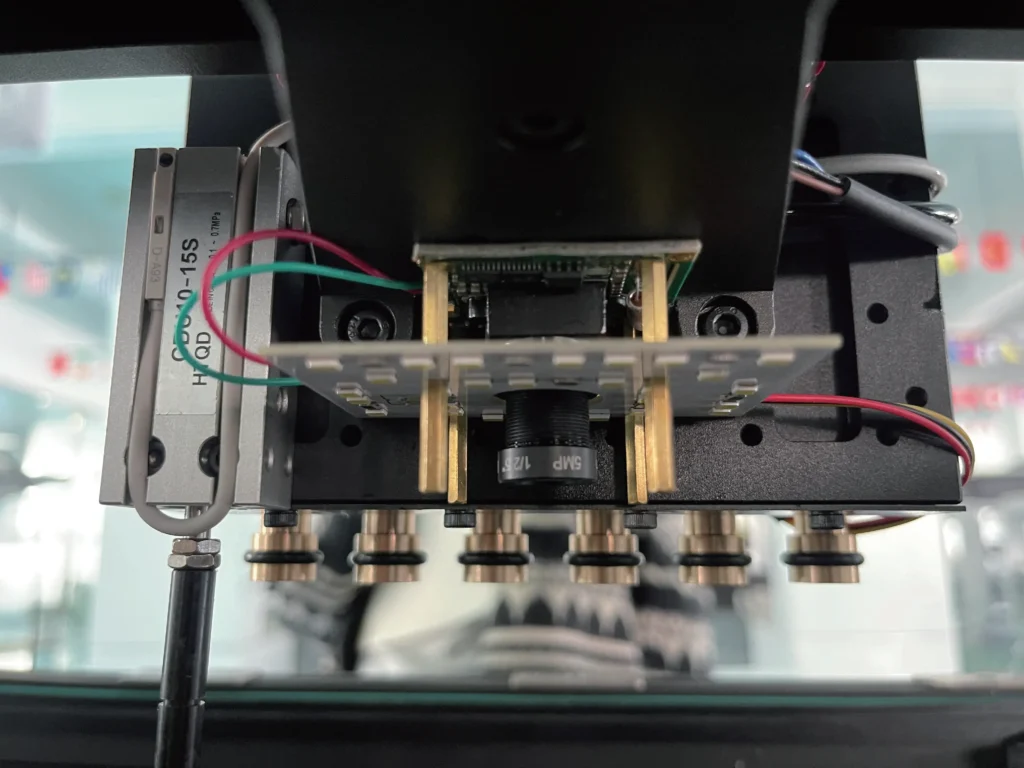

1. Hardware Components

- Industrial Cameras:

- Line scan cameras (for high-speed recognition)

- Area array cameras (for precise positioning, e.g. 5MP MARK camera in HW-F5)

- Lighting Systems:

- Ring lights, coaxial lighting (dual-source in HW-S6 for material adaptability)

- Scattering light sources for component contrast enhancement

- Auxiliary Sensors:

- Laser rangefinders (PCB warpage detection)

- Vacuum self-check sensors with visual confirmation

- Torque sensors in collaborative robot applications

2. Software Algorithms

- Image processing (edge detection, template matching)

- Deep learning models (defect prediction, path optimization)

- Coordinate transformation systems (image-to-mechanical mapping)

- WYSIWYG PCB simulation interfaces

II. Core Capabilities

1. Component Recognition & Positioning

- High-speed flying cameras capture 0402 (0.4×0.2″) to 0201 micro components

- Handles challenging conditions: blurred silkscreen, tilted components (HW-S6 enhanced algorithms)

- 360° component rotation with 0.1° precision (HW-A8)

2. Calibration & Compensation

- Nozzle center calibration (±0.05mm accuracy)

- Real-time PCB warpage compensation (laser measurement + auto-adjustment)

- Thermal expansion correction (environmental drift compensation)

- Spline-guided Z-axis movement for consistent focus (HW-S6)

3. Quality Control

- Pre-placement checks: polarity verification, lead deformation

- Post-placement 3D inspection: solder pad contact validation

- Component library management systems

III. Technology Evolution

1. Precision Advancements

- From 0.1mm (2000s) to 0.02mm today (HW-F5 0201 support)

- Laboratory systems achieving micron-level precision

2. Intelligent Features

- Rule-based algorithms → Machine learning → Deep learning

- MES integration for production data tracking

- AI-powered path optimization (HW-F5/S5)

3. Multi-Sensor Fusion

- Force sensors for placement pressure monitoring

- Spectral analysis for material verification

- Collaborative robotics with vision-guided obstacle avoidance

Emerging Technologies: Event-based cameras (100,000+ CPH), quantum dot sensors for low-light environments, and hybrid vision-force control systems.

IV. Model Comparison: HW Series Vision Systems

Pick-and-Place Machine

| Feature | HW-A8/A6L | HW-F5/S5 | HW-S6 |

|---|---|---|---|

| Camera System | 8 linear cameras (A8) 6×400K pixel (A6L) | Hybrid: Flying + Linear + Fixed 500W MARK camera | 5MP flying + 6MP MARK Dual light sources |

| Min. Component | 0402 (11mm) | 0201 (0.6×0.3mm) | 0201 with enhanced recognition |

| Speed | 15,000 CPH (A6L) | 84,000 CPH (S5 dual-arm) | 45,000 CPH |

| Special Features | Basic component library | AI path optimization Thermal compensation | Spline Z-axis Through-hole feeders |

| Applications | Entry-level SMT | High-mix microelectronics | Demanding precision tasks |

V. Application Scenarios

1. LED Manufacturing

- 3528/5050 large LEDs on flexible substrates (HW-A8L)

- Requires scattering light sources for contrast

2. Microelectronics Packaging

- 0201 resistors/capacitors, QFN chips

- Demands 6MP+ cameras for pin verification

3. Power Devices

- 40×40mm MOSFET/IGBT modules

- Special nozzles and lighting configurations required

Selection Criteria: Balance speed (CPH), precision (μm), and component compatibility. High-volume production benefits from HW-S5’s dual-arm configuration, while R&D environments may prefer HW-S6’s enhanced recognition capabilities. (Data references: IEEE Industrial Electronics Society publications 1990-2023 & HW technical documentation)