Laptop SMT Machine Assembly Line Complete Solutions

Design Objectives

To meet the production demands of laptop motherboards under 15.6 inches, supporting ultra-thin PCBs of 0.4mm and 01005 micro components. Compatible with the latest packaging processes for Intel/AMD chipsets (LGA 1851/BGA 1964), achieving ±20μm process stability.

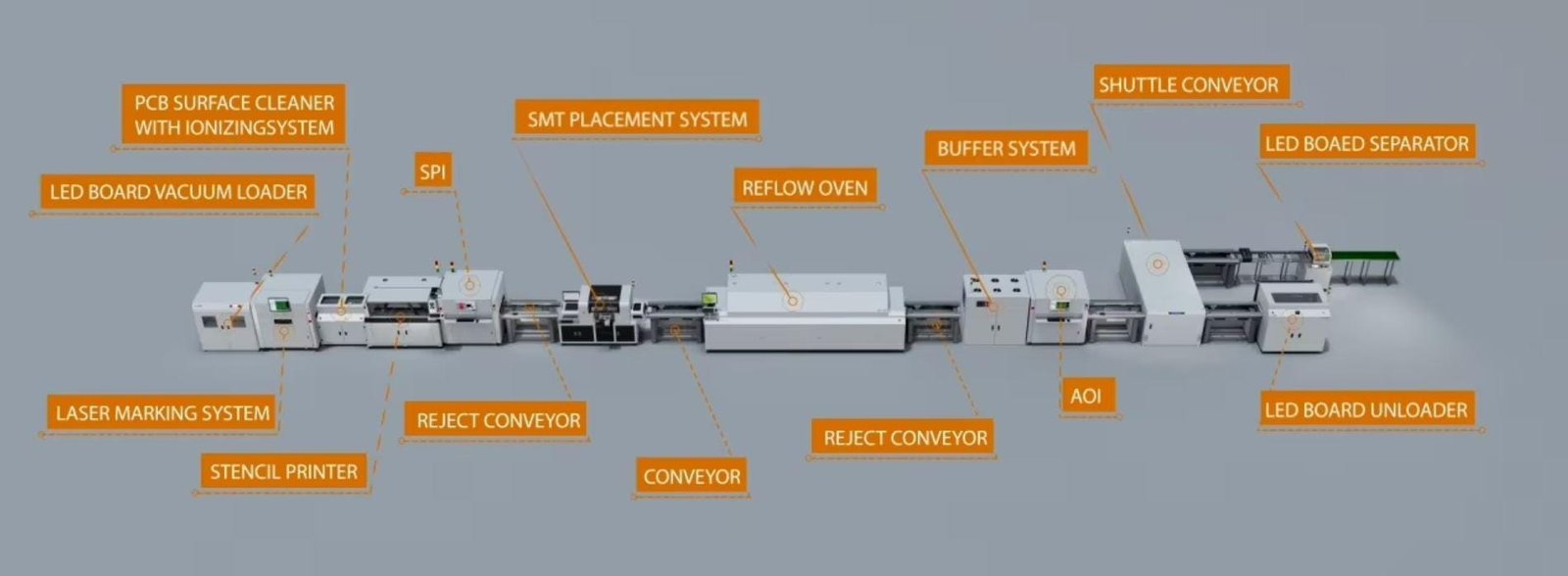

Core Equipment Configuration and Selection

| Equipment Category | Key Technical Parameters | Applicable Scenarios |

|---|---|---|

| Solder Paste Mixer | Dual-screw vacuum mixing (viscosity error ±3Pa·s), supports halogen-free solder paste, de-gassing rate > 95% | High-density motherboards solder paste preparation |

| SMT Loader | Four-track independent board supply, compatible with 0.3-3.0mm board thickness, speeds ≥1500 boards/hour (includes automatic edge cutting) | Mixed line production for multiple motherboard models |

| Solder Paste Printer | Electromagnetic drive squeegee, adjustable printing pressure from 0.1-20kg, supports 0.15mm pitch CSP components | High-precision area printing for CPU/GPU |

| SPI Machine | Multispectral 3D inspection (405nm blue light + 850nm infrared), solder paste height detection accuracy ±3μm | Intercepting defects in micro pads |

| Pick and Place | Refurbished FUJI NXT III or HW-G6, precision ±15μm (Cpk ≥1.8), supports high-speed placement at 0.25s/chip | Placement of 01005 components and LGA sockets |

| Micro Component Feeding System | Piezoceramic vibration feeding + 0201 dedicated material gun, wastage rate <0.1% | Placement of motherboard power management modules |

| Reflow Machine | 16 temperature zones with nitrogen protection, maximum chain speed 1.8m/min, supports Innolot curve (ΔT ≤2℃/temperature zone) | Dual-sided reflow soldering process |

| AOI Machine | 8μm optical resolution, deep learning algorithms for detecting solder defects/offset/polarity reversal, false positive rate <0.3% | Full inspection at board level |

| X-Ray Inspection Machine | Micro-focus 2μm resolution, 3D reconstruction of BGA solder balls, supports automatic judgement of void rates/bridging | Chip-level quality verification |

| Select Wave Soldering | Dynamic switching between dual wave (λ wave + disturbed wave), adaptive soldering angle (±5°), supports 0.5mm pitch connectors | Soldering USB/HDMI interfaces |

| Precision Dispensing Machine | Nano-level piezoelectric injection (dispensing volume 0.005ml), supports simultaneous operation of underfill glue & thermal grease | Chip bottom fill and heat dissipation module assembly |

| Laser Marking Machine | Fiber laser (1064nm), adjustable marking depth from 0.01-0.1mm, supports binding SN codes and QC data | Product traceability system |

| Docking Station | Six-axis leveling buffer table, load capacity of 50kg, supports real-time data interaction with the MES system | High-load motherboard transfer |

| SMT Unloader | Intelligent grading (OK/NG/Rework), NG products automatically labeled and trigger MES alerts | Quality closed-loop management |

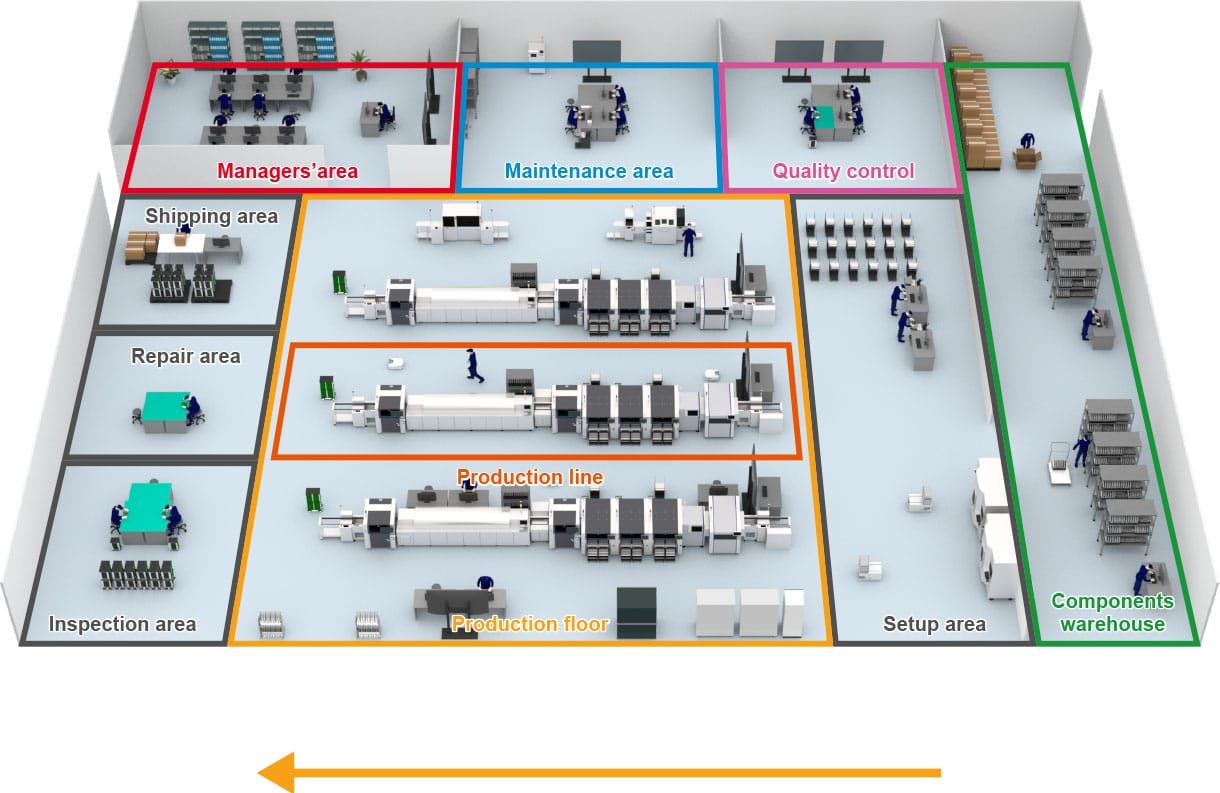

Laptop Production Line Layout and Capacity Optimization

1. Layout for Ultra-thin Boards (Dual-track Asynchronous Mode)

[Production Line Topology] Loader → Printer → SPI → Interfacing Station → PnP (NXT IIIx2) → Reflow → AOI → X-Ray ↓ Wave Soldering ← Dispensing Machine ← Laser Marking ← Unloader

Key Design Features:

- Deformation Prevention Module: Configured with a PCB preheating platform (40±2℃) from the printer to the reflow segment to reduce warpage risk.

- Dual-sided Process Flow: A-side placement → reflow → flip → B-side placement → second reflow, compatible with 0.4mm thin double-sided SMT.

- Thermal Management Area: Independent temperature control at the dispensing station (25±1℃) to ensure stable performance of thermal materials.

2. Capacity and Efficiency Model

| Indicator | Parameter | Optimization Measures |

|---|---|---|

| Theoretical Placement Speed | 78,000 CPH (NXT IIIx2) | Dual-track asynchronous operation increases equipment utilization by 15% |

| Actual Capacity (OEE 85%) | Output of 36,000 motherboards in a single shift (8h) | Smart feeding systems reduce downtime |

| Changeover Time | ≤20 minutes (fast change steel mesh + formula cloud synchronization) | Magnetic steel mesh + formula database call |

| Overall Throughput Rate | ≥99.5% (Quadruple detection interception) | AOI and X-Ray data linkage optimization |

Special Process Support for Laptop Motherboards

1. Chip Packaging Compatibility Solutions

- LGA Sockets: Dedicated nozzles (contact area >80%) + dynamic compensation for placement pressure (0.5-5N adjustable).

- Heat Dissipation Modules: Integrated dispensing machine for dual-component thermal grease mixing module (mixing ratio 10:1 ±1%).

- Board-Level Testing: Docking Station integrates ICT probes (optional), enabling electrical testing after soldering.

2. Reliability Enhancement Design

Process Chain: Three-proof coating (IPX4 level) → Stress testing (±50G vibration) → Aging testing (72h high temperature and high humidity) Detection Chain: SPC system real-time monitoring of CPK value (key parameters: solder paste thickness/BGA void rate)

Cost Control and Value-added Services

| Strategy | Implementation Plan | Benefits |

|---|---|---|

| Refurbished Equipment | NXT III vision system upgraded to 15μm, reflow soldering heat compensation module replaced | Reduced costs by 40%, precision at 90% of new machines |

| Domestic Alternatives | HW pick-and-place machine + Matrix VisionX AOI combination, compatible with Hermes standards | Overall investment reduced by 35% |

| Smart Operation and Maintenance System | Predictive maintenance module (vibration/temperature sensors) + cloud-based failure database | MTTR reduced to 1.5 hours |

| Process Package Support | Providing the “Laptop Motherboard Soldering Curve Library” (including parameters for mainstream models like Dell/HP/Lenovo) | Shortened trial production cycle by 3 days |

Supplier Collaboration Framework

| Clause | Content |

|---|---|

| Spare Parts Assurance | Spare parts center in South China/East China, Class A spare parts (laser heads/servo motors) delivered within 4 hours |

| Technical Training | Providing the “Ultra-thin Board SMT Process Manual” + 7 days on-site debugging (including anti-static/ESD specialties) |

Attachments

- Laptop motherboard 3D assembly simulation report (validating the feasibility of 01005 components)

- Refurbished equipment MTBF certification (≥10,000 hours)

- Dual-sided reflow soldering temperature curve template

This solution customizes the process chain to meet the high precision and reliability requirements of laptop motherboards, with triple cost-optimization strategies reducing initial investment by 28%. It is recommended to prioritize the validation of the 0.4mm thin board dual-sided process while simultaneously applying for UL/CE certification.