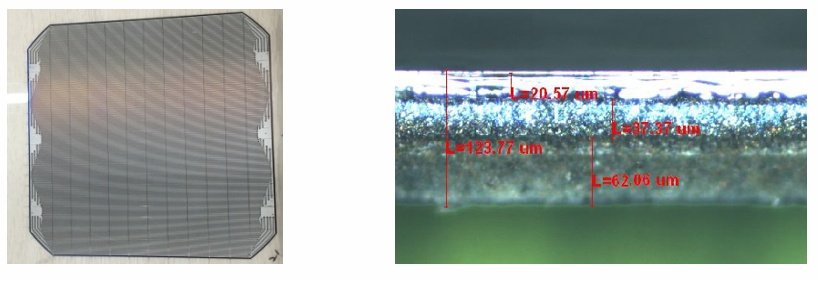

The high energy density of the focused ultraviolet laser causes a rapid increase in temperature on the surface of the material being processed, resulting in instant melting and vaporization. Coupled with platform movement, this creates linear cutting seams on the material surface to achieve the cutting objective.

Laser power (single pulse energy) is the primary factor affecting cutting depth and width. Tests conducted on silicon wafers yielded the graph below, which illustrates the relationship between laser power and the measured cutting depth and width. (Testing conditions: laser frequency at 70 kHz, cutting speed at 250 mm/s, utilizing multi-point cutting technology.)

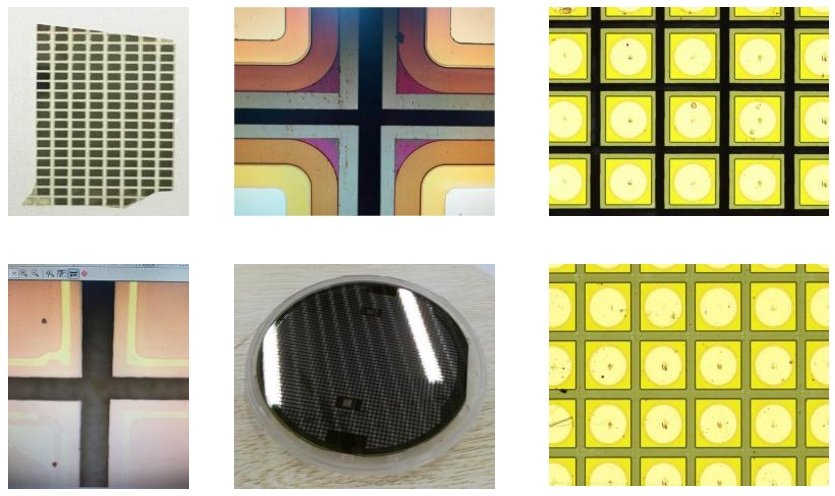

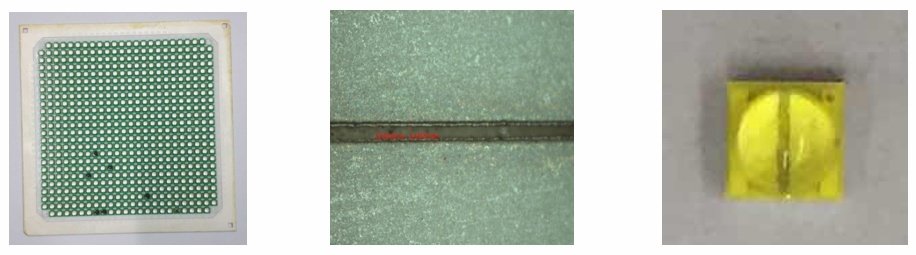

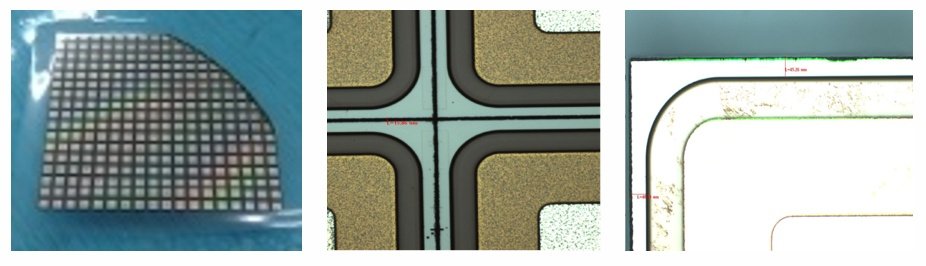

Primarily used for cutting LED red and yellow light silicon wafer chips, as well as for cutting special materials such as ceramics and metals.

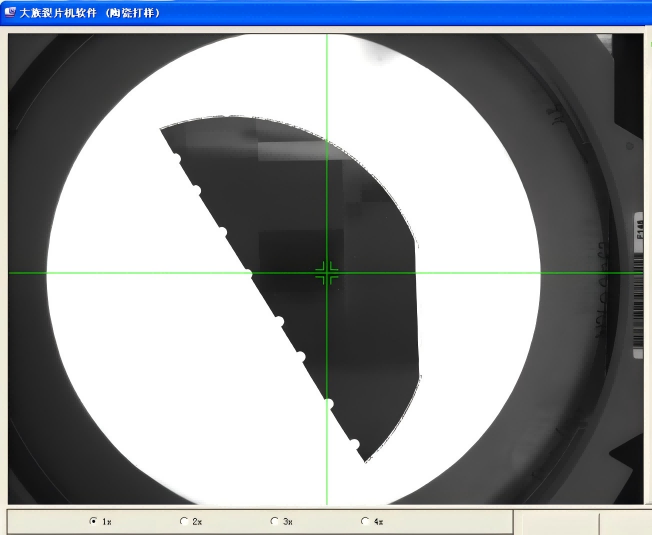

Equipped with a Wide-Angle Camera for Automatic Contour Recognition

Loading does not require distinguishing between whole and broken pieces, eliminating the need for breaking piece settings and edge searching, significantly saving time during the breaking operation.

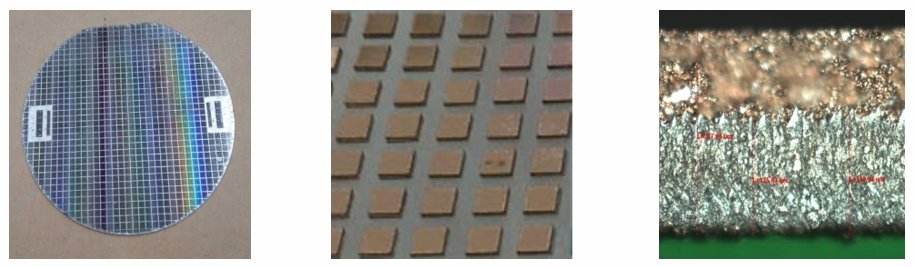

Stable Back-Cutting System

Provides stable imaging; combined with large-size double-sided (DD) technology and mature cutting techniques, it can back-cut 6-inch wafer pieces.

Multi-Point Technology

The machine is equipped with multi-point lenses that effectively control re-melting, achieving better cutting results. This cutting technology is leading in the industry.

High-Precision Workbench

Full closed-loop control ensures that the displacement error across the full travel range is within ±1µm. The excellent acceleration and deceleration performance effectively improves the system’s output capacity per unit time.

Stable High-Quality Cleaning and Glue Application System

The machine is equipped with an automatic cleaning and glue application system, making it simple and convenient to use. All parameters for cleaning and glue application are monitored comprehensively to ensure the quality of chip cutting.

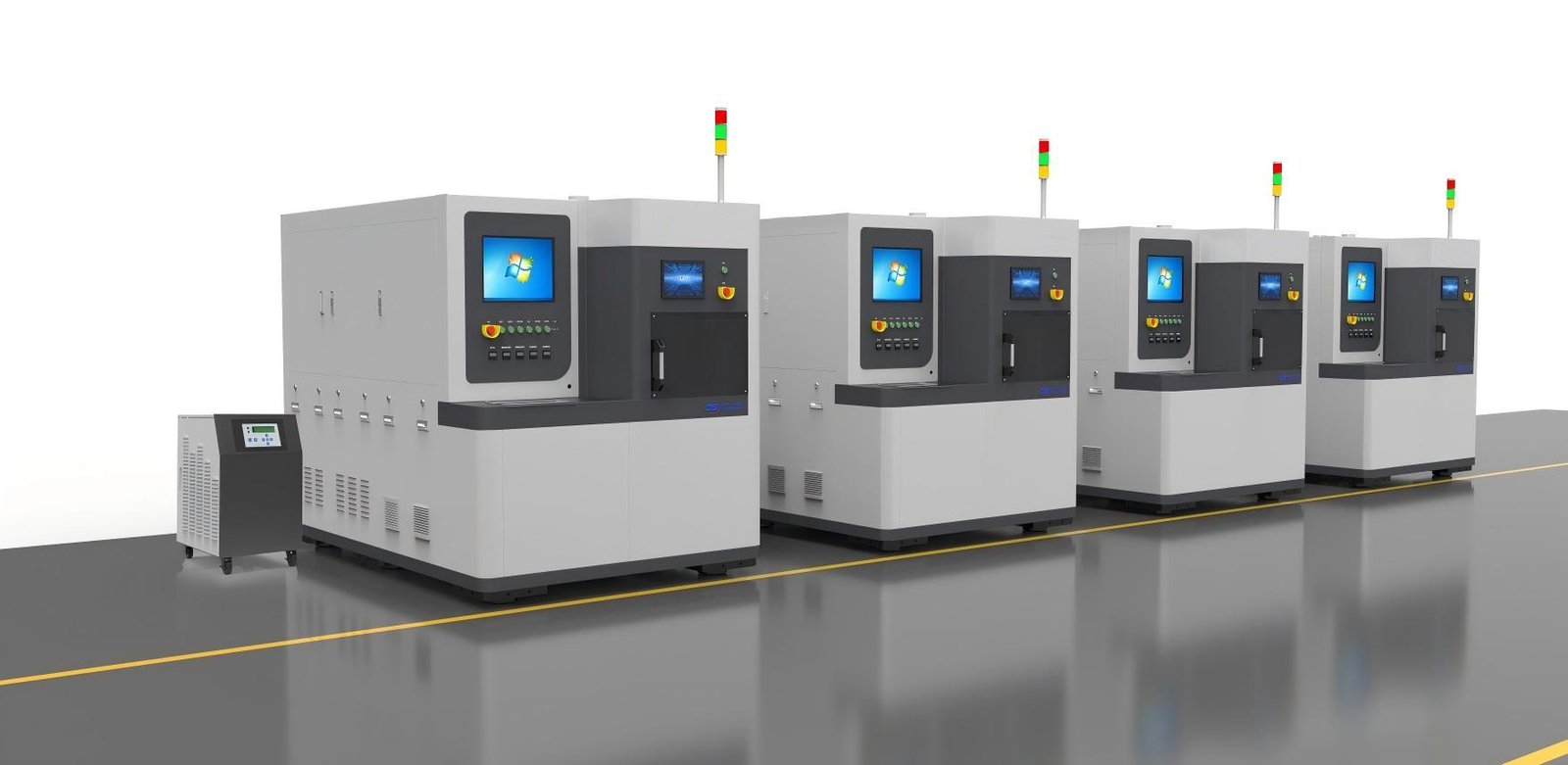

A large number of devices are operating stably at various customer sites, with their performance fully recognized and affirmed.

Cutting Efficiency: For 4-inch wafers (4646 standard), operating 22 hours per day, the machine achieves a cutting capacity of ≥45 pieces/day for both front and back cutting.

Cutting Yield: The appearance yield of the cut pieces is ≥98.5%, and the electrical yield before and after cutting essentially maintains zero loss.

Equipment Stability: Equipment utilization rate is ≥98%, with the alarm rate controllable at less than 3 times per day.

| No. | Component Name | Origin | Model | Quantity | Function and Parameters |

| 1 | Laser | Self-made/Purchased | 355 | 1 | Wavelength: 355nm Frequency: Adjustable 0-500KHz Laser Power ≤ 15W |

| 2 | XY Worktable | Self-made | 300600 XY | 1 | Stroke: 300600mm Y-axis Repeat Positioning Accuracy ≤ 1μm Verticality (within ±50mm): ±1μm Flatness: ±2μm |

| 3 | DD Motor | Purchased | / | 1 | Absolute Positioning Accuracy: ±20 arc-sec Repeat Positioning Accuracy: ±3 arc-sec Mounting Flatness ≤ 8μm |

| 4 | CCD | Purchased | / | 4 | Wide-angle CCD: 1 with 5 million pixels Upper CCD: 2 with 130W pixels Lower CCD: 1 with 1.3 million pixels |

| 5 | Cleaning and Coating Device | Self-made | / | 1 | Automatic Cleaning and Coating With protective liquid and water flow monitoring |

| 1 | Power Requirements | 220V/Single Phase/50Hz/16A; Power supply fluctuation: <5% |

| 2 | Ambient Temperature | 20~24℃; Temperature variation ±1℃ |

| 3 | Ambient Humidity | 40~70%; No condensation |

| 4 | Compressed Air | 0.65~0.75MPa, Equipment interface pipe diameter φ12 |

| 5 | Factory Vacuum | -0.06MPa ~ -0.08MPa, Equipment interface pipe diameter φ8 |

| 6 | Cooling Water | Use ordinary bottled purified water for the chiller, change once a month |

| 7 | Washing Water Pressure | Water pressure 0.15~0.3MPa, needs filtered water, filter diameter ≤ 25μm |

| 8 | Exhaust Purification System | Equipment interface internal pipe diameter φ100 corrugated pipe |

| 9 | Environmental Vibration Requirements | Foundation amplitude <5μm; Vibration acceleration <0.05G |

| 10 | Situations to Avoid | ● Areas with garbage, dust, and oil mist; |

| ● Areas with significant vibration and impact; | ||

| ● Areas where pharmaceuticals and flammable/explosive materials can be touched; | ||

| ● Areas near high-frequency interference sources; | ||

| ● Areas where temperatures can change abruptly; | ||

| ● Environments with high concentrations of CO2, NOX, SOX, etc. |

The distance between the equipment and other equipment, or the distance from the wall, must be at least 800mm.

Equipment Dimensions: 1350x2170x1750mm (W*L*H), height does not include the three-color light.

Equipment Weight: 3 tons (excluding chiller).

Rm3A08 (4th Floor) Block D, Huashengtai Technology Park, No.36 Hangkong Road, Baoan District, Shenzhen City, China

© 2026 All Rights Reserved.