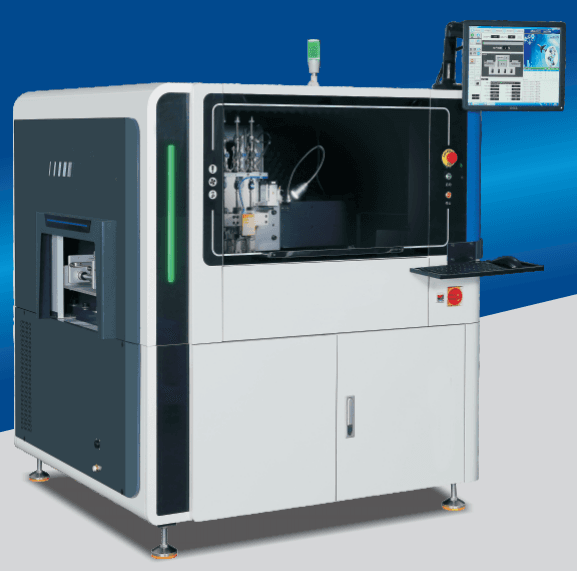

The operating software running in the Windows environment including production data,management data,device parameters,editing programs,and all /O signal diagnosis,can be completed on the host, with a user-friendly interface.The application of high-tech technology makes the device simple and efficient,easy to use,and has good operability.

The industrial special HD camera and the self-developed visual correction software constitute a visual system.The deviation between the PCB hole position and the programmed coordinates can be seen, and allcoordinates can be quickly and automatically corrected to align wth the actual PCB hole position,ensuring the accuracy of the insertion and greatly improving the programming efficiency.

When inserting missing parts, it can achieve missing part detectionand has are-insertion function.

| Item | Description |

|---|---|

| Insertion speed | 0.4 seconds per piece |

| PCB loading and unloading time | 3s |

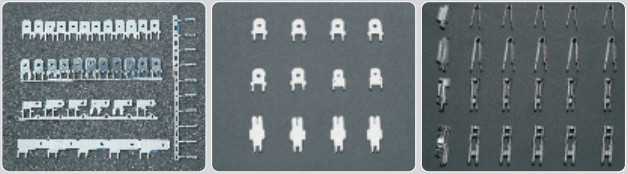

| Component packaging method | Jointly, in rolls, in bulk |

| Dimensions of detachable PCB | Max 380mm×280mm; Min 50mm×50mm (can be customized) |

| Number of insertion heads | Can be set with 1–4 insertion heads to insert terminals of different specifications |

| Terminal thickness requirements | 0.6mm ≤ Terminal ≤ 1.2mm |

| PCB board requirements | The edge of the backup plate needs to have positioning holes; the component aperture is 0.5mm larger than the component foot |

| Insertion direction | Can be set from 0 to 360 degrees in increments of 1 degree |

| Component body distance | The distance between components is 2mm (high density can be customized) |

| Component fixation method | Two feet are perpendicular to each other, and the component is bent towards both sides (Optional inner bend) |

| Control system | Self-developed control system, Industrial PC-motion control card for efficient control |

| Display system | 17 inch color LCD display |

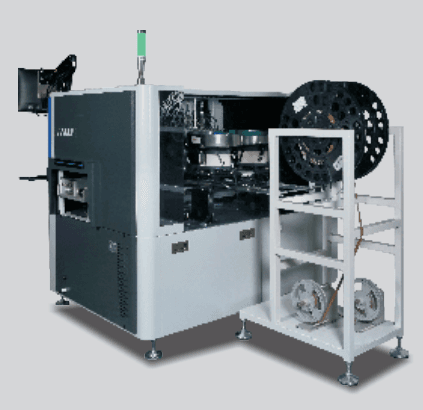

| Material supply method | Bowl feeder, packaging in rolls/continuous feeder |

| Motion accuracy | 0.001mm per pulse |

| Motor system | Panasonic servo controller, motor |

| Programming function | Online visual programming, visual correction, and simple Excel spreadsheet process |

| Data input | USB interface input, manual input |

| Communication interface | RS-232C can connect MES / MES solution can be customized |

| Using the power supply | Single phase 220VAC, 50/60HZ, 2KVA |

| Air pressure | 5–6 kg/cm² |

| Machine noise | ≤55 dB |

| Ambient temperature | 10℃–30℃ |

| Environmental humidity | 30%–70% |

| Equipment dimensions | 1750mm * 1350mm * 1750mm |

| Equipment weight | 1500kg |

Rm3A08 (4th Floor) Block D, Huashengtai Technology Park, No.36 Hangkong Road, Baoan District, Shenzhen City, China

© 2026 All Rights Reserved.