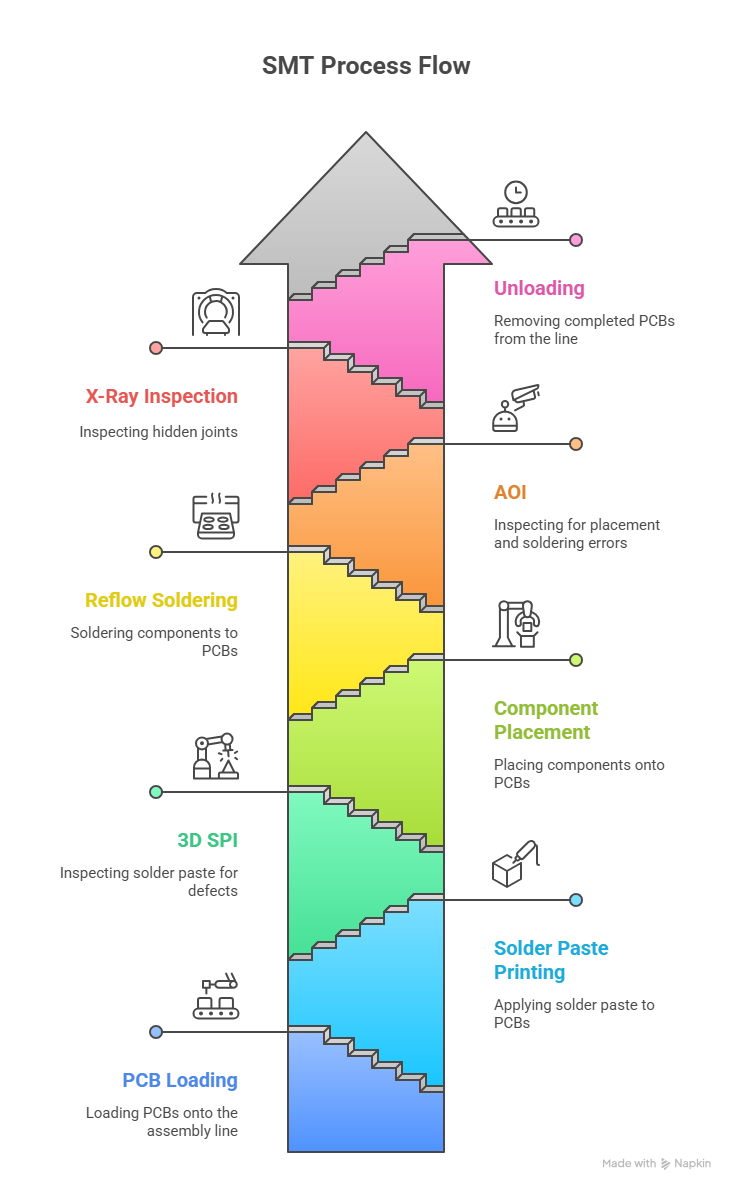

The Ultimate Guide to the SMT Process Flow: From Solder Paste Printing to AOI Inspection

Introduction: A Manufacturing Revolution in the Microcosm From smartphone processors and medical device control boards to automotive electronic sensors, the creation of this precision hardware