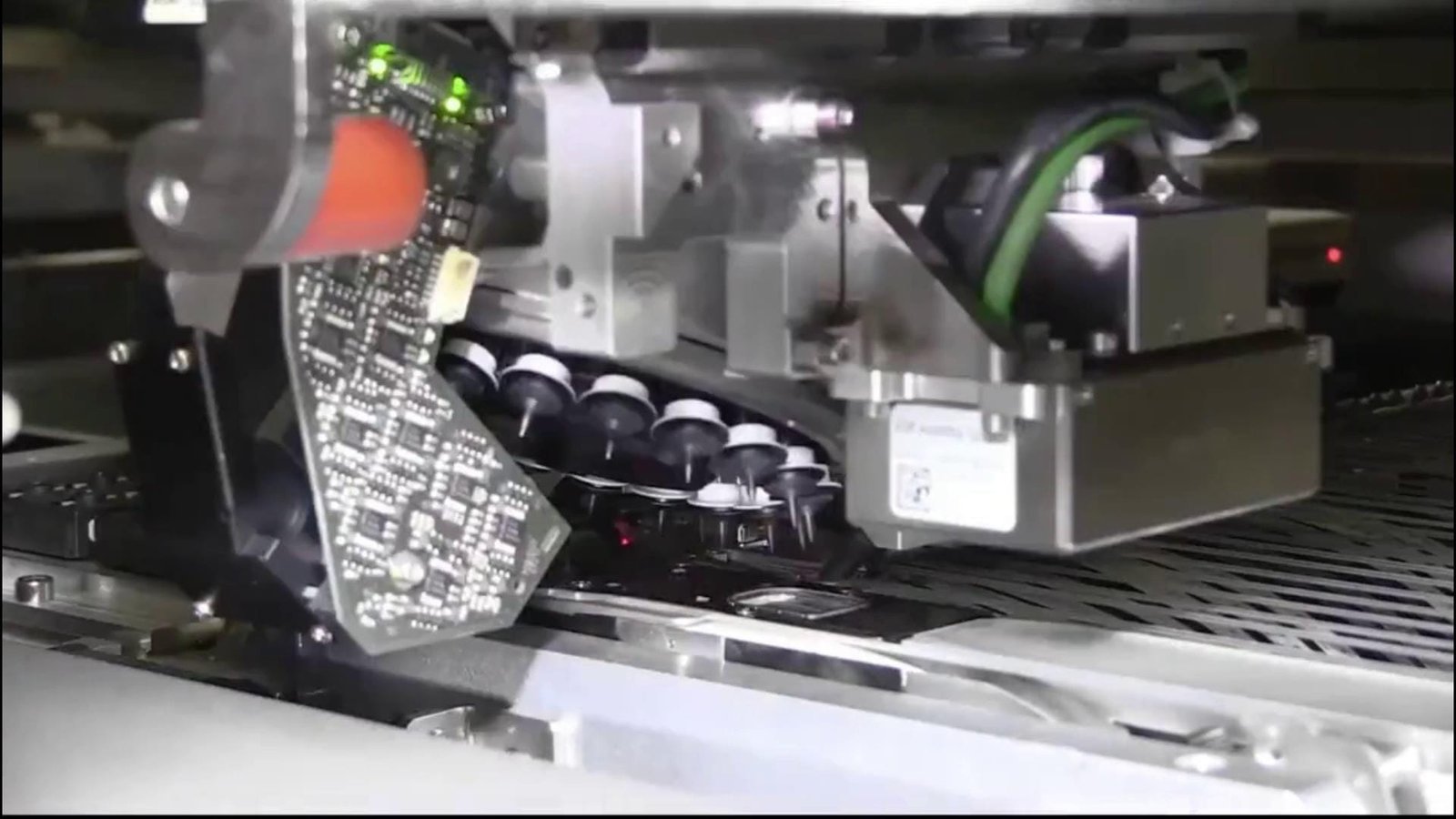

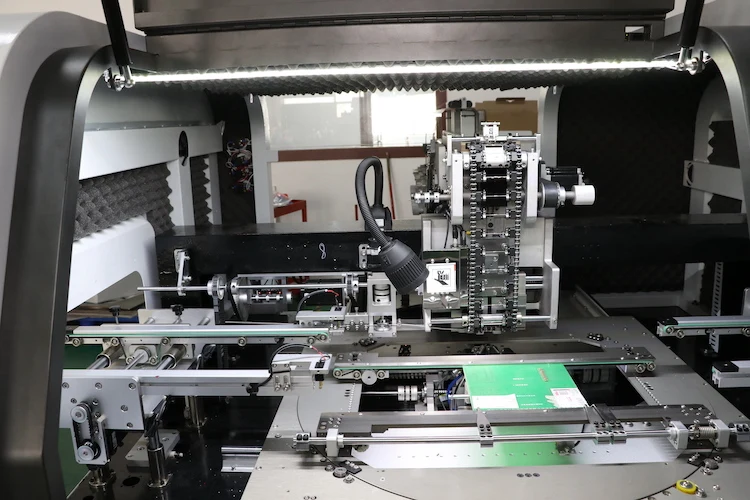

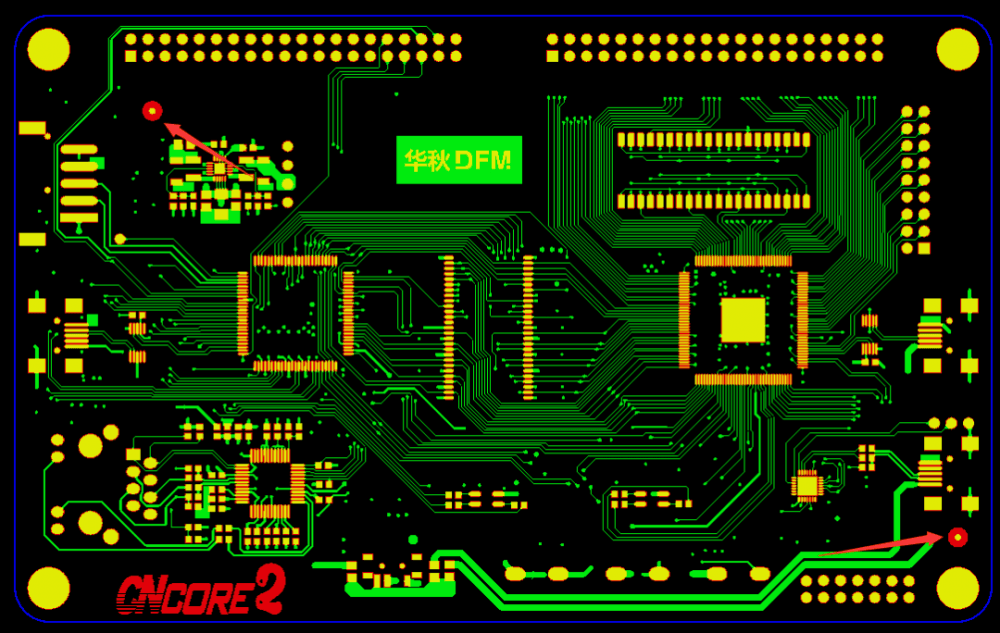

Wholesale Automatic Pick and Place Machines: 5 Equitment for Diverse Production Needs

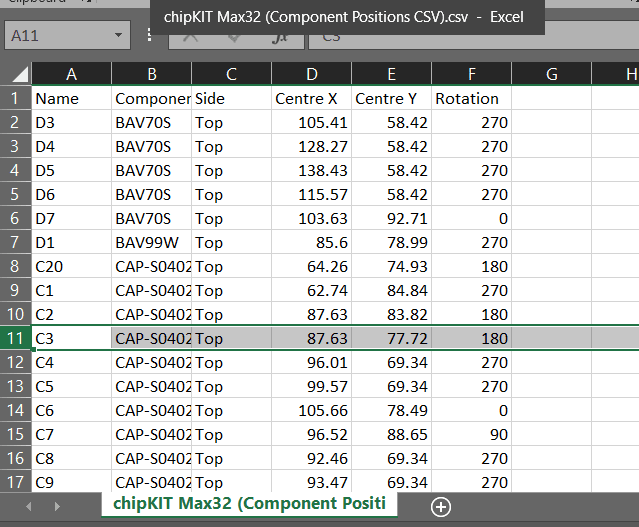

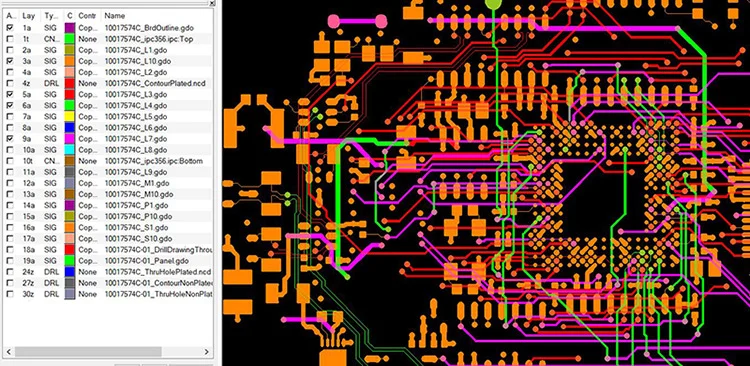

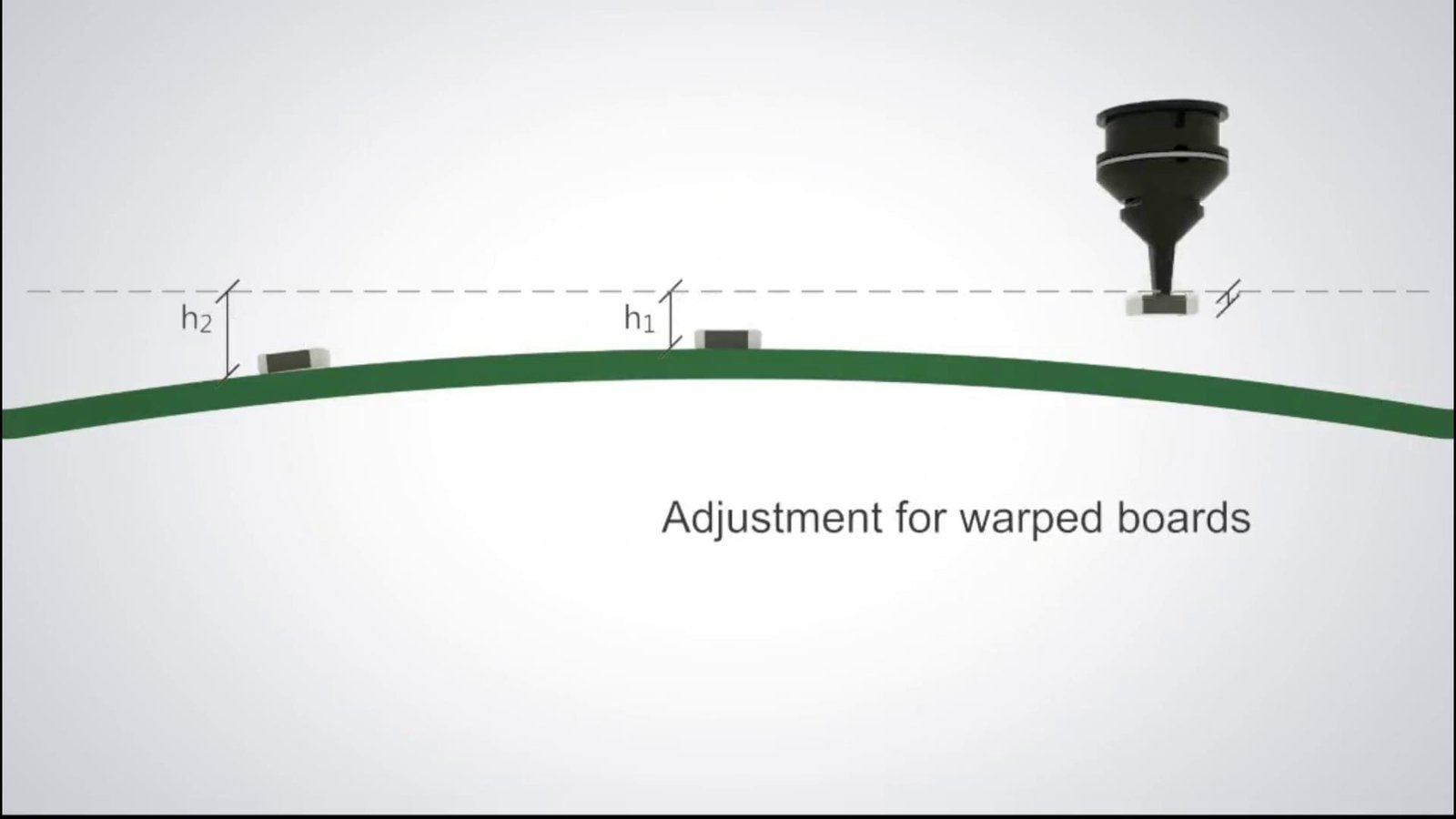

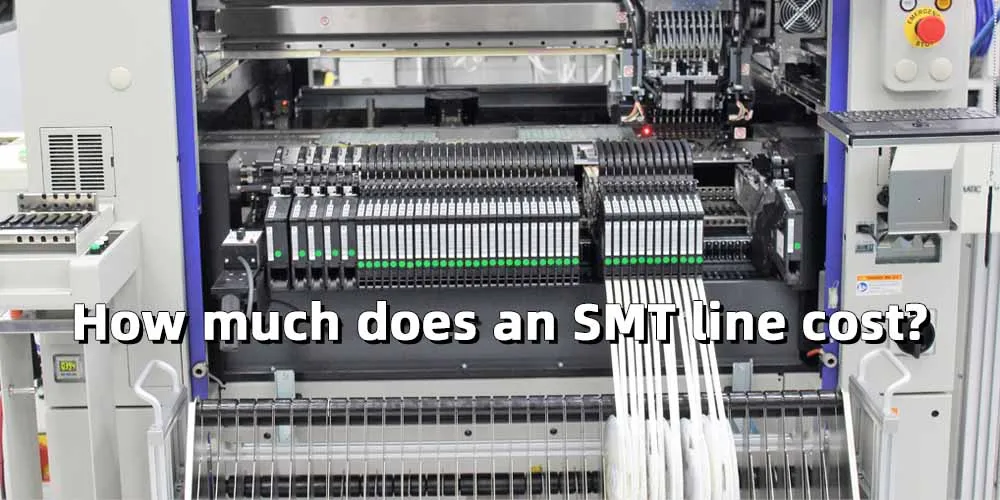

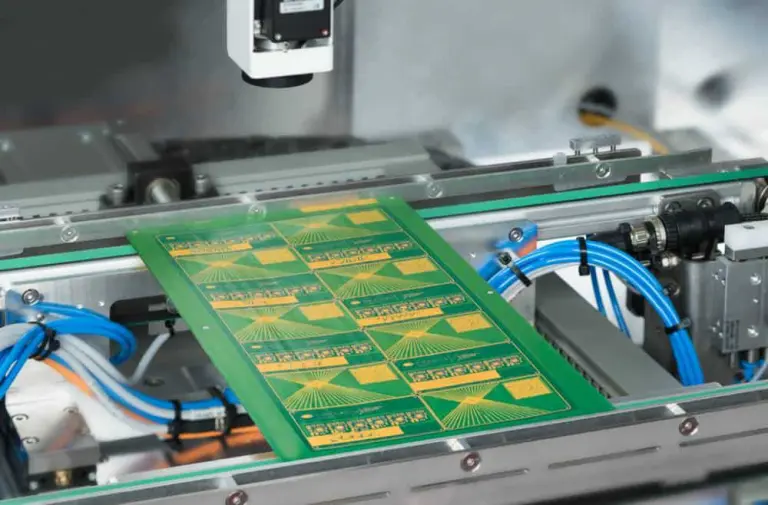

For manufacturers and wholesalers seeking high-efficiency SMT (Surface Mount Technology) equipment, the HW series offers five distinct automatic pick-and-place machines tailored to varied production scales,