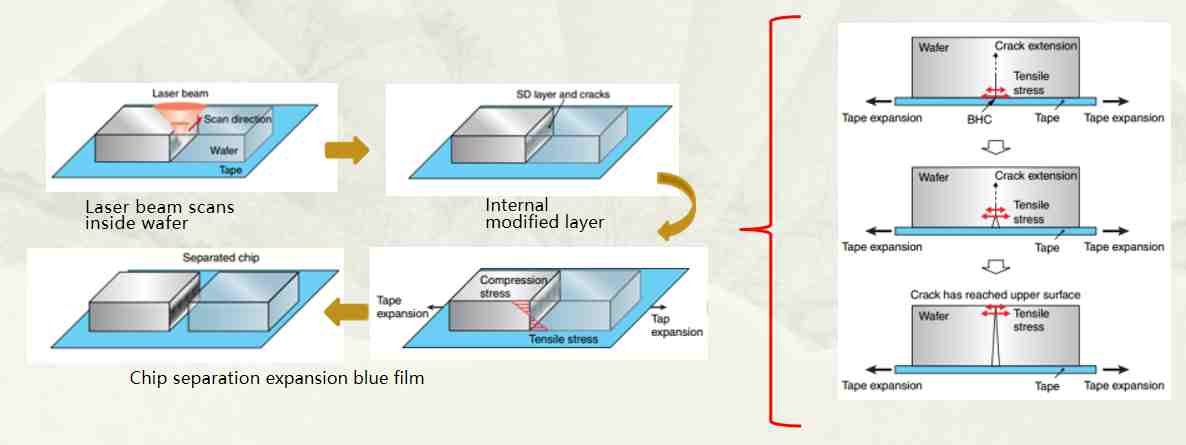

Beim Laserschneiden mit interner Modifikation wird der Infrarot-Laserstrahl im Inneren des Wafers fokussiert und ein internes " Der Wafer wird in einzelne Chips geschnitten, indem eine externe Kraft auf den Wafer ausgeübt wird.

Basierend auf der ausgereiften LED-Würfelschneider-Plattform mit höherer Präzision und höherer Effizienz Bereiten Sie DSI - MC -9201 vor.

| Seriennummer | Gerät Name | Land der Herkunft | Modell | Menge | Funktionen und Parameter |

| 1 | Laser | China | U- schnell | 1 | 3.0W@50KHZ;3.5W@100KHZ (Lichtausgang) 50~200 KHZ einstellbar |

| 1 | X/Y linearer Arbeitsturm | Selbst gemacht | 400*600 XY | 1 | 1) Hub: 400X 600 mm 2) Auflösung: Y= 0,1 μm; X=0,5um 3) Y-Wiederholgenauigkeit der Positionierung: <=1μm (see Appendix 1) 4) X straightness: 1 um / 300 mm (see Appendix 2) |

| 2 | DD Motor und Treiber | Importieren | / | 1 | 1) Maximale Geschwindigkeit: 2.4rps 2) Nenngeschwindigkeit: 2.0 U/s 3) Auflösung des Encoders: 26214400 p/ rev 4) Ebenheit der Installationsoberfläche: weniger als 10 um |

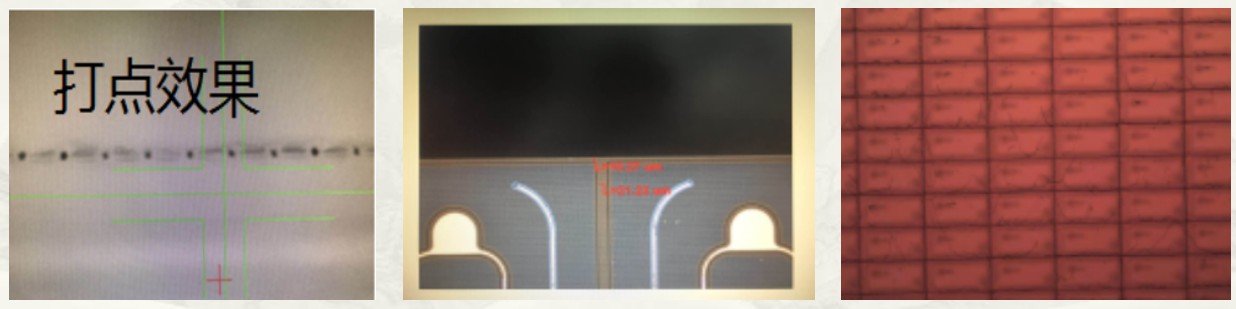

| 3 | CCD | Outsourcing | / | 4 | 1) Weitwinkel 500W 2) Größen- und Winkelkorrektur 1,3 Millionen Pixel; 3) Fokus 300.000 Pixel 4) Telezentrisches Objektiv mit hoher Pixelzahl |

| 4 | Z-Achse | Importieren | / | 2 | 1) 0-8mm Bereich 2) Wiederholgenauigkeit der Positionierung: +/-1 um |

2. DRA-Schneidetiefenkompatibilität und verbesserte Stabilität Der neue Sensor ist besser mit MINI-Filmquellen kompatibel und kann dünnere Produkte messen, was die Nachverfolgung verbessert.

2. DRA-Schneidetiefenkompatibilität und verbesserte Stabilität Der neue Sensor ist besser mit MINI-Filmquellen kompatibel und kann dünnere Produkte messen, was die Nachverfolgung verbessert. HL-C2 :Bewegungsauflösung: ca. ±5μm Messdicke: 80um oder mehr

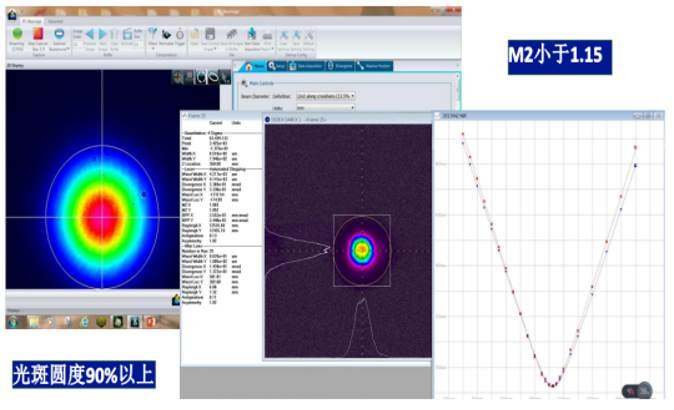

HL-C2 :Bewegungsauflösung: ca. ±5μm Messdicke: 80um oder mehr LK-H008W (Neu) :Bewegungsauflösung: ca. ±1μm Messdicke: 30um oder mehr3. Unabhängige Rechte an geistigem Eigentum gewidmet Laser Durch die Optimierung und Verbesserung der Laser, Unabhängig entwickeln wettbewerbsfähige Laser, Verbessern Sie die Qualität der Laserschneiden LED-Wafer.

LK-H008W (Neu) :Bewegungsauflösung: ca. ±1μm Messdicke: 30um oder mehr3. Unabhängige Rechte an geistigem Eigentum gewidmet Laser Durch die Optimierung und Verbesserung der Laser, Unabhängig entwickeln wettbewerbsfähige Laser, Verbessern Sie die Qualität der Laserschneiden LED-Wafer.

4. Verbesserte Alarmausfälle und verbesserte Stabilität Durch kontinuierliche Optimierung kann die Alarmrate innerhalb von 1%~5% kontrolliert werden. Das heißt, dass die Maschine bei einer Produktion von 100 Stück nur 1 bis 5 Mal Alarm schlägt.5. Neue Vision: Ausgestattet mit drei verschiedenen Banden von Hintergrundbeleuchtungsquellen, verfügt es über eine breitere Kompatibilität und eine automatische visuelle Erkennung und Positionierung.6. Hauptdaten Erscheinungsausbeute: größer oder gleich 99,5% Elektrische Ausbeute: branchenführender Wirkungsgrad : 30 Produktgröße: 9*27 mil Die Produktionskapazität von Vier-Zoll-Wafern beträgt ≥ 7500 Wafer / Monat, und die Produktionskapazität von Sechs-Zoll-Wafern beträgt ≥ 5000 Wafer / Monat. Stabilität: Mobilität der Maschine ≥ 96% .7 Seit der Entwicklung der Anlage wurden viele technische Schwierigkeiten überwunden, und viele Technologien sind die ersten in der Branche. Und viele Patente wurden angemeldet.

4. Verbesserte Alarmausfälle und verbesserte Stabilität Durch kontinuierliche Optimierung kann die Alarmrate innerhalb von 1%~5% kontrolliert werden. Das heißt, dass die Maschine bei einer Produktion von 100 Stück nur 1 bis 5 Mal Alarm schlägt.5. Neue Vision: Ausgestattet mit drei verschiedenen Banden von Hintergrundbeleuchtungsquellen, verfügt es über eine breitere Kompatibilität und eine automatische visuelle Erkennung und Positionierung.6. Hauptdaten Erscheinungsausbeute: größer oder gleich 99,5% Elektrische Ausbeute: branchenführender Wirkungsgrad : 30 Produktgröße: 9*27 mil Die Produktionskapazität von Vier-Zoll-Wafern beträgt ≥ 7500 Wafer / Monat, und die Produktionskapazität von Sechs-Zoll-Wafern beträgt ≥ 5000 Wafer / Monat. Stabilität: Mobilität der Maschine ≥ 96% .7 Seit der Entwicklung der Anlage wurden viele technische Schwierigkeiten überwunden, und viele Technologien sind die ersten in der Branche. Und viele Patente wurden angemeldet.

| 1 | Energiebedarf | 220V/Einphasig/50 HZ/16A; Schwankungen im Stromnetz: <5% The power plug of the device is a standard three-flat plug |

| 2 | Umgebungstemperatur | 22~26℃; Temperaturschwankung ±1℃ |

| 3 | Feuchtigkeit der Umgebung | 40~70% Keine Kondensation |

| 4 | Pressluft | 0,6~0,7Mpa, Durchmesser der Ausrüstungsschnittstelle p12 mm |

| 5 | Anforderungen an Umgebungsvibrationen | Amplitude der Stiftung <5μm Vibration acceleration <0.05G |

| 6 | Zu vermeidende Situationen | ● Orte mit viel Müll, Staub und Ölnebel; ● Orte mit vielen Vibrationen und Stößen; ● Orte, an denen Medikamente sowie brennbare und explosive Materialien berührt werden können; ● Orte in der Nähe von hochfrequenten Störquellen; ● Orte, an denen sich die Temperatur schnell ändert; ● In CO2, NOX In Umgebungen mit hohen Konzentrationen von SOX, etc. |

Rm3A08 (4. Stock) Block D, Huashengtai Technology Park, No.36 Hangkong Road, Baoan District, Shenzhen City, China

© 2026 Alle Rechte vorbehalten.