We have a full range of wave solder machine, nitrogen is an option, please contact us to discuss your individual requirement.

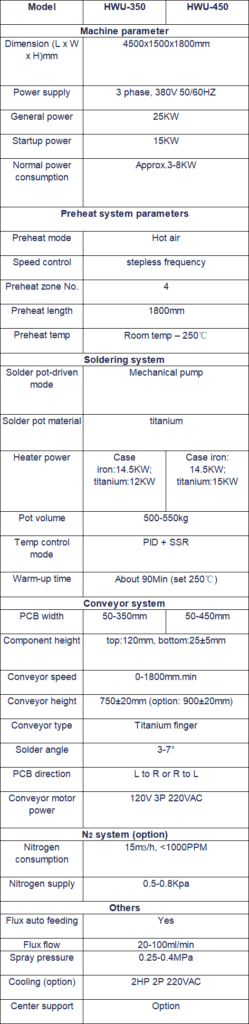

Modell | HWU-350 | HWU-450 |

Parameter der Maschine | ||

Dimension (L x W x H)mm | 4500x1500x1800mm | |

Energieversorgung | 3 phase, 380V 50/60HZ | |

General power | 25KW | |

Leistung beim Start | 15KW | |

Normaler Stromverbrauch | Approx.3-8KW | |

Preheat system parameters | ||

Preheat mode | Hot air | |

Speed control | stepless frequency | |

Preheat zone No. | 4 | |

Preheat length | 1800mm | |

Preheat temp | Room temp – 250℃ | |

Soldering system | ||

Solder pot-driven mode | Mechanical pump | |

Solder pot material | titanium | |

Heater power | Case iron:14.5KW; titanium:12KW | Case iron: 14.5KW; titanium:15KW |

Pot volume | 500-550kg | |

Temp control mode | PID + SSR | |

Warm-up time | About 90Min (set 250℃) | |

Fördersystem | ||

PCB width | 50-350mm | 50-450mm |

Component height | top:120mm, bottom:25±5mm | |

Geschwindigkeit des Förderbandes | 0-1800mm.min | |

Höhe des Förderbandes | 750±20mm (option: 900±20mm) | |

Conveyor type | Titanium finger | |

Solder angle | 3-7° | |

PCB direction | L to R or R to L | |

Conveyor motor power | 120V 3P 220VAC | |

N2 system (option) | ||

Nitrogen consumption | 15m3/h, <1000PPM | |

Nitrogen supply | 0.5-0.8Kpa | |

Andere | ||

Flux auto feeding | Ja | |

Flux flow | 20-100ml/min | |

Spray pressure | 0.25-0.4MPa | |

Cooling (option) | 2HP 2P 220VAC | |

Center support | Option | |

Rm3A08 (4. Stock) Block D, Huashengtai Technology Park, No.36 Hangkong Road, Baoan District, Shenzhen City, China

© 2025 Alle Rechte vorbehalten.