Application area: Optical communication, LiDAR, RF, microwave, infrared, commercial laser, military industry, aerospace.

Powerful Process Capability: The machine supports multiple processes, including eutectic bonding, adhesive dipping, dispensing, UV curing, and more.

Multiple Loading and Unloading Methods: It accommodates various loading options such as blue film, gel pack/waffle pack, and track loading, while also supporting wafer map functionality.

Multi-Chip Application: Supports up to 100 different types of nozzles for fully automatic replacement, enhancing versatility for multi-chip applications.

Highly Flexible Software: The programmable software system allows for flexible application and supports different products and various process applications with free switching capabilities.

Options Available: Includes an automatic loading and unloading system and an assembly line material transfer system for increased efficiency.

| Model | HW-15D | |

| Placement Process | Eutectic, adhesive dipping (Ag paste) | |

| Equipment Application | COC/COS; AOC/COB; Gold-Box; RF | |

| Efficiency | 15-30s/pcs (eutectic), 7-10s/pcs (dipping glue) | |

| Precision | ±3 μm | |

| Placement System | X/Y/Z stroke | 350mmx500mmx50mm |

| Axis of Rotation | 360°, repeated position accuracy: ±0.2° | |

| Minimum Suction Size | 0.15*0.2mm | |

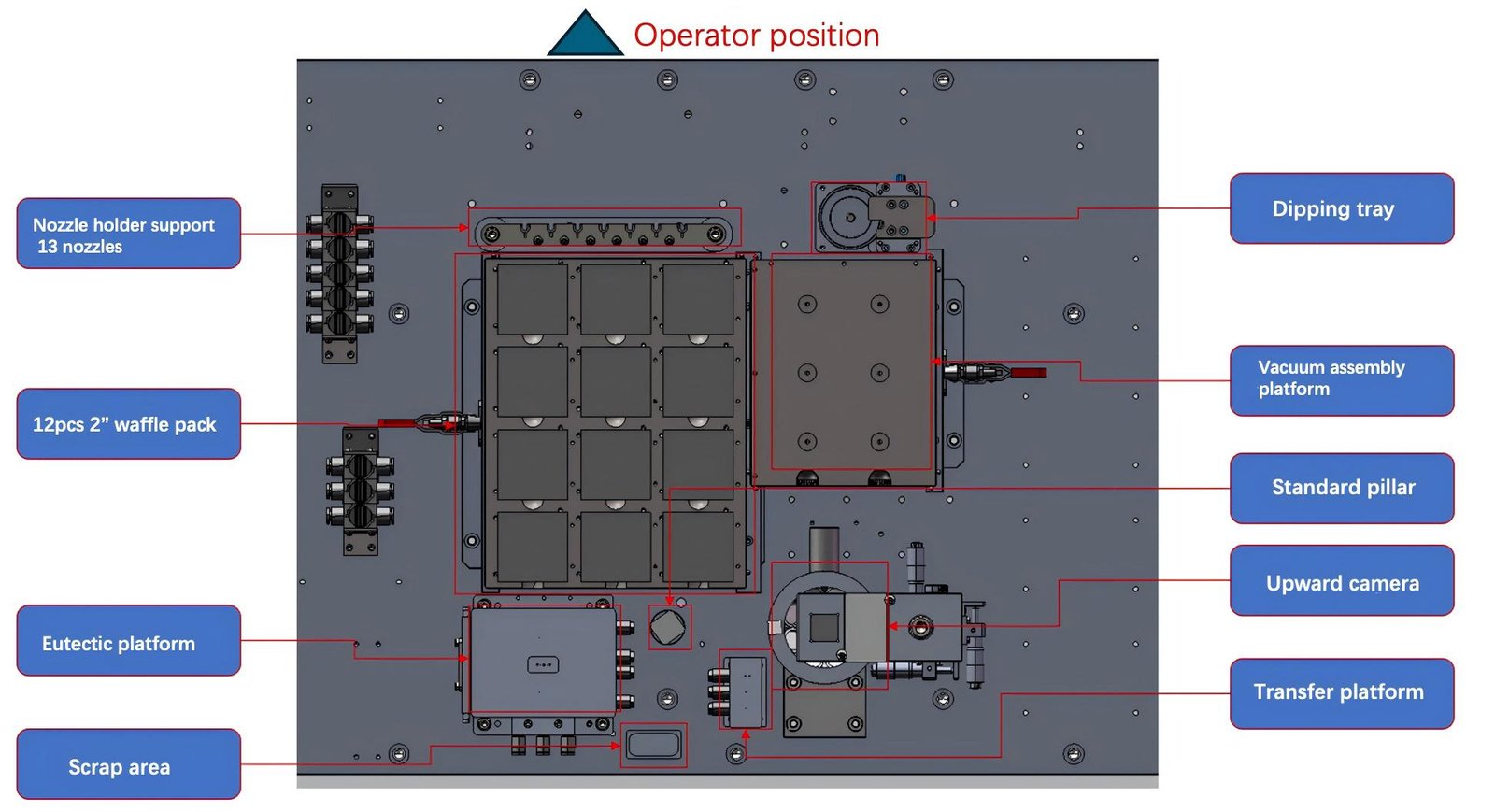

| Nozzle | Automatic nozzle replacement. One nozzle holder supports 13 nozzles. | |

| Pressure | 10-2000g (Pressure real-time closed-loop feedback) Accuracy: ±10%, 10 ± 1g | |

| Eutectic System | Eutectic platform | 1 |

| Heating mode | Pulse heating | |

| Temperature range | 25-400°C (option: max 600°C) | |

| Temperature rise rate | Max 50°C/S, adjustable, accuracy: ±3°C | |

| Bonding Process | Nitrogen protection; real-time display of temperature curve | |

| Feeding system | Waffle Pack Gel-Pak | Standard: 2×2″ / 4×4″ Qty can be customized by customer’s need. |

| Vision System | Two downward-looking cameras and one high-magnification upward-looking camera. Each camera is equipped with programmable 4-way lights (collimated white light, ring RGB tri-color light) | |

| Power supply | 200-240V 50HZ single-phase 20A | |

| Weight | 2000kg | |

| Compressed air | 0.6Mpa 300L/min | |

| Nitrogen | 0.3Mpa 30L/min 99.9% | |

| Vacuum | -80kpa 120L/min | |

| Environment temperature | 23 ±2°C | |

One of the machine module layouts, it can be adjusted as customer’s needs.

Rm3A08 (4th Floor) Block D, Huashengtai Technology Park, No.36 Hangkong Road, Baoan District, Shenzhen City, China

© 2026 All Rights Reserved.