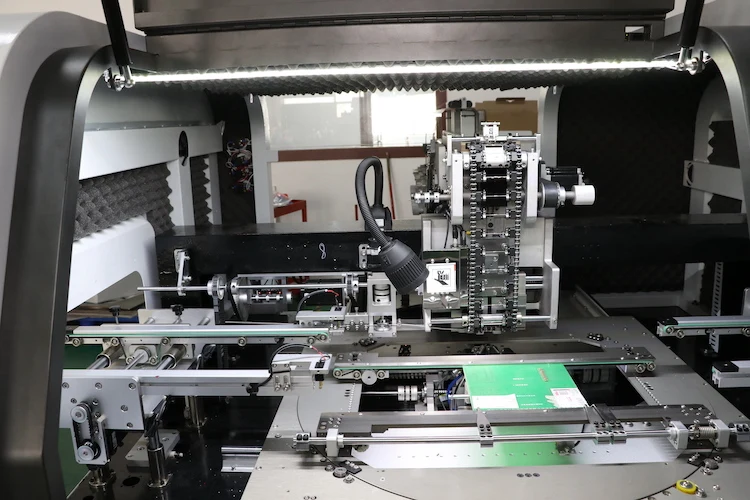

Component Auto Insertion Machines

Component auto insertion machines are specialized equipment used in the electronics manufacturing industry to automate the process of inserting electronic components onto printed circuit boards (PCBs). These machines are designed to handle various types of components based on their physical characteristics and application requirements. Below is a detailed overview of the three main types, along with additional insights on technological advancements, industry applications, and market trends.

1. Machine d'insertion radiale

A Machine d'insertion radiale is specifically designed for components with leads that extend radially from the body’s perimeter. Commonly used for capacitors, resistors, and diodes, these machines feature multiple dispensing heads that can accommodate different component types. They allow for adjustments in clinch lead angle, ensuring proper seating and forming of the leads on the PCB.

Innovations and Applications:

- Machine Vision Systems: Modern radial insertion machines often include high-precision vision systems (like CCD cameras) that detect component polarity and lead bending in real-time, optimizing the insertion path and reducing calibration time.

- Industry Relevance: Vital in producing polarity-sensitive components for automotive and lighting industries, where manufacturers face increasing demands for LED assemblies.

Recommended style: HWR-20

- Au lieu d'un travail laborieux, il s'agit d'une production très efficace.

- L'UPH théorique peut atteindre 24 000 points/heure.

- Fonctionnement simple, grande stabilité, grande précision.

- It can be used to place a wide variety of components, it’s more flexibility for products.

- Coût d'entretien réduit.

- La conception structurelle robuste permet de surmonter facilement les moments générés par les mouvements à grande vitesse et les perturbations de la stabilité causées par les contraintes mécaniques, de sorte qu'il peut s'adapter confortablement au rythme de fonctionnement à haut rendement de la ligne de production et maintenir la stabilité du fonctionnement pendant une longue période.

2. Machine d'insertion axiale

An Machine d'insertion axiale targets components with leads extending from one end, such as axial resistors and capacitors. The design focuses on inserting components with precise lead placement, and automated feeders allow for continuous operation, minimizing manual involvement.

Caractéristiques principales :

- Insertion Accuracy: Machines typically achieve insertion precision of ±0.05mm and can handle a variety of component sizes.

- Industry Usage: Important for standardizing mass production with rigorous quality assurance in sectors like telecommunications and consumer electronics.

Recommended style: HWR-30

Cette machine d'insertion automatisée est conçue pour le placement de composants axiaux dans les lignes d'assemblage de circuits imprimés.

The theoretical speed of HWR-30 axial insertion machine is up to 24000UPH, making an efficient production, shorter changeover time, it can realize the fully automatic production line, also allows the traceability of operations, and connects to the factory’s system.

We have all solutions for inserting radial, axial, pin, terminal, connector, and odd form components, it’s appreciated to contact us for getting more insertion machines catalogue.

3. Machine à insérer les formes irrégulières

Odd-form Insertion Machines cater to components that do not conform to the radial or axial lead configurations, like connectors, switches, and transformers. These machines are adaptable and often feature customizable tooling to handle unique geometries.

Technical Advancements:

- Precision Mechanisms: They incorporate systems that accurately position and insert components at non-standard angles or depths.

- Versatility: Ideal for applications requiring a mix of standard and specialized components, enhancing production flexibility.

Recommended style: HWR-30

- Remplace le travail manuel et réduit les coûts de main-d'œuvre.

- La taille compacte de la machine permet de l'intégrer facilement dans une ligne de production SMT.

- Vitesse théorique jusqu'à 6000 points/heure, efficacité et productivité élevées.

- Fonctionnement simple, programmation aisée, stabilité et fiabilité.

- Déploiement flexible de la production

- Coût d'entretien réduit.

- Conception modulaire en fonction des différentes méthodes d'alimentation pour fournir diverses solutions d'alimentation. En fonction des exigences de production, configuration flexible, pour répondre aux composants à broches, aux composants irréguliers de l'alimentation en continu.

- Les pinces et les buses peuvent être adaptées à différents types de composants façonnés, faciles à remplacer.

- Logiciel basé sur Windows, interface entièrement en anglais, facile à utiliser.

Additional Insights

Technological Innovations

- AI Integration: Some machines utilize AI algorithms for adaptive handling of slightly deformed components, minimizing scrap rates.

- Flexible Manufacturing: Machines with modular designs allow for quick fixture and nozzle changes, accommodating small batches and varied productions.

Industry Applications and Challenges

- Emerging Fields: Adaptations for high-frequency PCBs in 5G technology, which require low-stress insertion techniques to prevent signal interference.

- Operation Pain Points: Frequent calibration needs for high-precision machines and the reliability of consumables like nozzles and fixtures.

Market Trends

- Growth in Demand: The global PCB insertion equipment market reached $1.8 billion in 2023, with a projected growth of 26% driven by automotive electronics, particularly in EVs.

- Sustainability Focus: Innovations such as servo motors replacing pneumatic systems have reduced energy consumption by 40%.

Comparative Overview

| Dimension | Machine d'insertion radiale | Machine d'insertion axiale | Machine à insérer les formes irrégulières |

|---|---|---|---|

| Typical Components | Radial electrolytic capacitors, LEDs | Axial resistors, diodes | Connectors, transformers |

| Precision Requirement | Medium (±0.1mm) | High (±0.05mm) | Custom (±0.02~0.2mm) |

| Production Compatibility | Suitable for large-volume single components | Medium-volume standardized production | Small-batch mixed production |

| Upgrade Cost | Low (high modularity) | Medium | High (custom tooling needed) |

| Leading Manufacturers | Universal Instruments | Juki | Mycronic |

Case Studies

- Automotive ECU Production:

- Challenge: Inserting high-temperature components (like 125°C rated capacitors) necessitates PCB pre-heating to prevent lead loosening.

- Solution: Integrating localized heating modules into radial machines to maintain temperature control within ±2°C.

- Wearable Device Miniaturization:

- Challenge: Inserting Micro-USB connectors with a 0.5mm pitch requires extreme precision.

- Solution: Employing odd-form machines with piezoelectric ceramics for nano-level adjustments.

tag:Component Auto Insertion Machines