SMT pick and place machine Workflow and Principles

1. Feeder Automatic Loading: Firstly, the operator places the circuit board to be assembled at the feeder position of the SMT pick and place machine. Typically, a feeder is used to provide the circuit board and ensure it is properly positioned and secured.

2. Automatic Identification and Calibration: The SMT pick and place machine uses a vision system or sensors to identify the position and orientation of the circuit board and calibrate it to ensure accurate component placement.

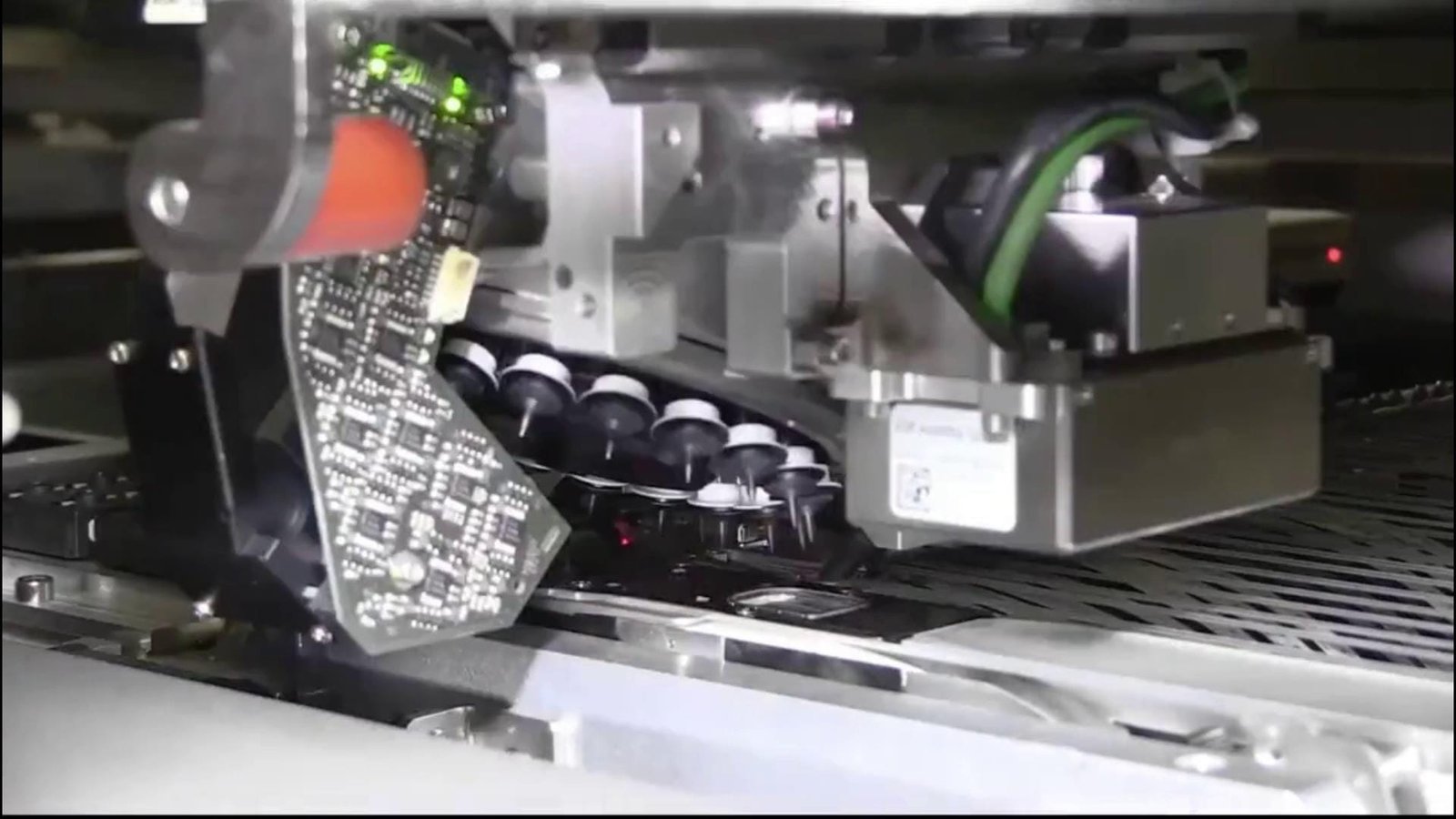

3. Feeding and Picking Components: The SMT pick and place machine retrieves surface mount components from the feeder, which typically includes trays, tape, or tubes containing the components. The machine uses a vacuum nozzle or other fixtures to pick up the components from the feeder.

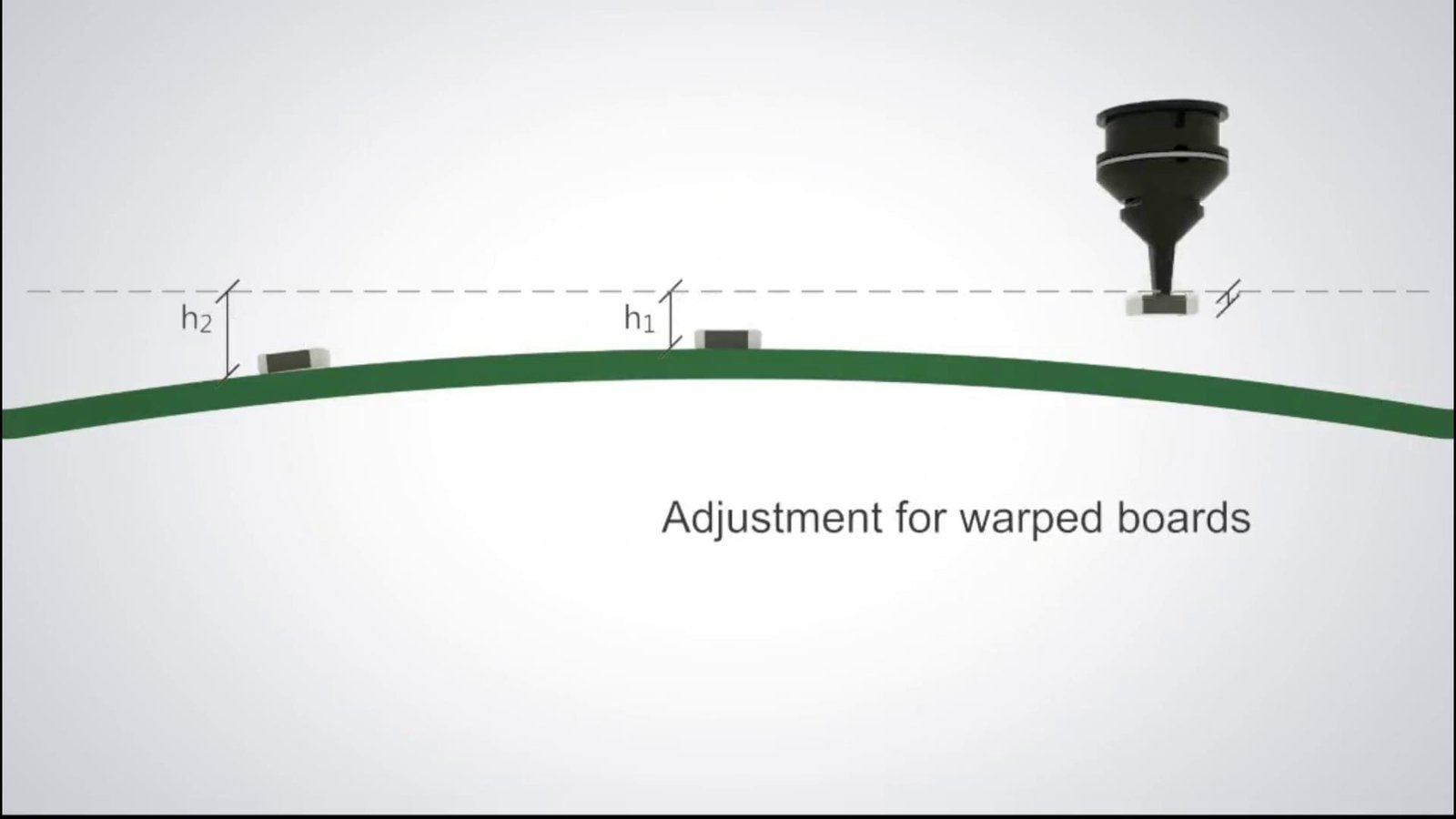

4.Precise PCB Positioning and Alignment: The SMT pick and place machine accurately positions the picked components at predetermined locations on the circuit board. It uses a precise positioning system, such as vision guidance or laser ranging, to ensure the components align with the pads.

5.Component Installation: Once the components are accurately positioned, the SMT pick and place machine gently places the components onto the pads (or other connection areas) of the circuit board. Typically, hot air or infrared heating is used to melt the solder, securely attaching the components to the circuit board.

Automatic speed switching, precise deceleration during release, and then precise pressure application.

Automatic speed switching, precise deceleration during release, and then precise pressure application.

Can also handle micro-curved surfaces.

Can also handle micro-curved surfaces.

6.Inspection and Correction: After installation, the SMT pick and place machine may check the quality and correctness of the soldering using vision systems or sensors. If any issues are found, the machine may automatically make adjustments or trigger alarms for repairs.

7.Discharging: Finally, the assembled circuit board is removed from the output position of the SMT pick and place machine, ready for subsequent process steps such as reflow soldering, testing, and packaging.

Different Types of Pick and Place Machines:

- Arch-type: The component feeders and PCB are fixed, while the pick and place head moves between the two.

- Turret-type: The pick and place head is mounted on a rotating turret, selecting different nozzles and components by rotation.

- Modular-type: Operates in parallel with multiple independent units to increase placement speed.

Recommandation relative à la machine de prélèvement et de pose de CMS

HW-S5 Machine automatique de prise et de mise en place de haute précision

Le placement combiné à deux bras permet la vitesse de placement la plus rapide, soit 84 000 CPH (dans nos conditions optimales).

HW-F5 Machine automatique de prise et de placement de haute précision

Configuration de la tête de placement intégrée à haut rendement (installation rapide et facile)

Performance de pointe : 42 000 CPH (dans des conditions optimales)

HW-A8 Machine automatique de prise et de dépose de diodes électroluminescentes (LED)

Découvrez la machine de placement SMT HW-A8 haute performance, dotée de 8 caméras de vision industrielle, de servomoteurs Panasonic et d'une plate-forme de stabilité en granit. Obtenez une précision de ±0,05 mm avec une vitesse de 40K CPH pour les bandes LED, les ampoules, les pilotes et bien plus encore. Solution SMT de qualité professionnelle avec capacité de placement à 360°.

Hightlywin: China SMT Pick and Place Machine Manufacturer