Using HW-A8 as an Example, Explore How to Equip Your LED Production Line with a Beast of Performance

1. Introduction

As global emphasis on energy conservation and environmental protection grows, the LED lighting industry is experiencing unprecedented development. From household bulbs to commercial lighting and complex landscape illumination, the presence of LEDs is everywhere. Behind this is the strong support of modernized and large-scale production technology, with surface mount technology (SMT) being at its core.

Within the entire SMT production line, the pick and place machine is undoubtedly the “heart.” Its speed, precision, and reliability directly determine the quality of the final product and production efficiency. However, LED lighting products—especially LED strips, tubes, and panel lights—have specific requirements for pick and place machines.

This article will delve into these requirements and use the professional LED pick and place machine, HW-A8 Fully Automatic Pick and Place Machine, as an example to provide you with a comprehensive purchasing guide that will help you make the most informed investment decision.

2. What is an SMT Pick and Place Machine and Its Role in LED Production Lines

In simple terms, SMT is a technology for soldering electronic components directly onto the surface of printed circuit boards (PCBs). A typical SMT production line process is as follows:

- Board Loader → Solder Paste Printer → Pick and Place Machine → Reflow Oven → AOI Automatic Optical Inspection → Board Unloader

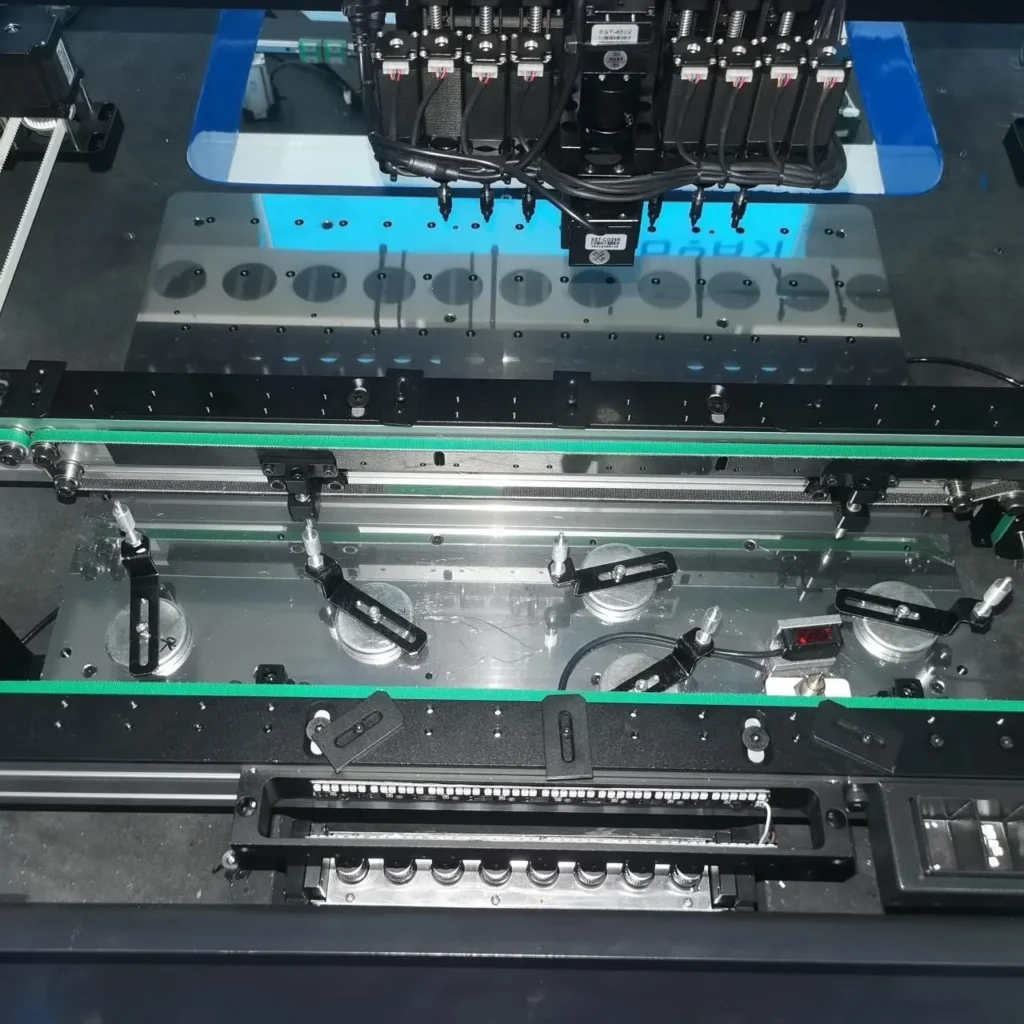

The core mission of the pick and place machine is to pick LED chips, resistors, capacitors, and other components from feeders with extremely high speed and precision, calibrate them through a high-precision vision system, and then accurately place them at designated positions on PCBs that have been printed with solder paste, awaiting the next step of reflow soldering.

3. Special Requirements for LED Lighting Production Regarding Pick and Place Machines

Not all pick and place machines can meet the demands of LED lighting production. The unique production needs present four core challenges, which the HW-A8 is specifically designed to overcome.

1. Capability to Handle Long PCBs: Challenging Length Limits

- Industry Pain Point: LED tubes and strips typically have PCB lengths of 1.2 meters, 1.5 meters, or even longer. Ordinary pick and place machines cannot handle such size and will limit production flow.

- Solution Example (HW-A8): The HW-A8 pick and place machine is built for long boards, with a track system that maximally supports 1200mm × 500mm PCBs. This means it can easily handle all mainstream 1.2-meter LED lamp boards and even reserves space for longer non-standard products. Its sturdy track, segmented support, and clamping system effectively prevent bending and vibrations of long boards during high-speed transmission and placement, ensuring placement accuracy.

2. High-Speed and High-Efficiency Placement: Racing Against Time

- Industry Features: Although the number of component types on LED boards is small, the quantity is massive (hundreds or thousands of LED beads) in a highly repetitive array layout. This places extreme demands on placement speed (CPH – Components Per Hour).

- Solution Example (HW-A8): The HW-A8 features a market-leading dual gantry and 16 placement heads (8 per arm) luxury configuration. Two gantries work independently at the same time, doubling efficiency. Its theoretical placement speed reaches 60,000 CPH, with an actual IPC9850 speed of 48,000 CPH. This means it can efficiently complete the placement tasks of a large number of LED beads and is a true production “beast.”

3. Special Handling of Components: Precise Identification and Gentle Placement

- Industry Characteristics: LED chips (such as 2835, 5050, 5730, etc.) are sensitive to static, have polarity differences, and various reflective characteristics on their surfaces. Some products also require the attachment of lenses and other irregular components.

- Solution Example (HW-A8): The HW-A8 is equipped with a robust visual identification system. Each placement head corresponds to a high-speed flying recognition camera, which can complete identification and calibration while picking components and flying to the placement point without stopping, greatly improving efficiency. Its advanced visual algorithm can accurately identify components ranging from the smallest 0402 to 17mm and various LED chip polarity markings, effectively preventing reverse errors.

4. Convenience of Programming and Optimization: Simplifying Complexity

- Industry Features: The array layout of LED boards can make manual programming highly cumbersome and inefficient.

- Solution Example (HW-A8): The HW-A8 is equipped with a self-developed intelligent operating system (based on Windows 7), which is specifically optimized for LED production. It supports functions like quick programming of array boards, one-click coordinates copying, and intelligent path optimization. Operators only need to set the coordinates of the first unit to quickly generate the program for the entire board, significantly shortening changeover and programming time.

4. Selecting a Dedicated Pick and Place Machine for LEDs: The Procurement Checklist Using HW-A8 as a Model

When evaluating a pick and place machine for LEDs, consider the following checklist to see how HW-A8 perfectly meets each requirement:

| Consideration Factor | Key Requirements | HW-A8’s Performance |

|---|---|---|

| PCB Size Range | Must support PCBs of 1.2 meters or longer | Perfectly supports 1200mm x 500mm, tailored for long board production. |

| Placement Speed (CPH) | The higher, the better; focus on actual IPC speed | Theoretical 60,000 CPH, IPC 48,000 CPH; dual gantry with 16 heads, industry-leading. |

| Placement Accuracy | High precision to ensure light efficiency consistency | XY axis accuracy ±0.05mm, fully meets high-density LED placement requirements. |

| Visual System | Flying camera, strong identification ability | 16 high-speed flying cameras + MARK camera, achieves “fly and shoot” for high efficiency and precision. |

| Feeder Station Capacity | Enough to support the variety of production materials | Provides 64 8mm feeder stations, more than sufficient for the relatively single material type of LED production lines. |

| Software Usability | Simple programming, supports array optimization | Self-developed software, specifically optimized for LEDs, supports CAD import and quick array programming. |

| Device Stability | Sturdy structure for long-term stable operation | Overall weight of 2200kg, solid materials ensure stability and durability under high-speed operation. |

5. Complete LED SMT Production Line Solutions

A high-performing HW-A8 pick and place machine requires equally outstanding “teammates” to work in harmony. To avoid production bottlenecks, an effective LED SMT solution should include:

- Long board solder paste printer: Able to evenly print solder paste on 1.2-meter long PCBs.

- High-speed HW-A8 pick and place machine: The core powerhouse of the production line.

- Multi-zone long board reflow oven: At least 8-10 zones to ensure even heating of long boards during soldering, avoiding deformation and cold solder joints.

- Online AOI (Automatic Optical Inspection): Immediately detects defects such as misplacements and reversals after soldering, key to quality assurance.

Choosing a supplier like Winsmt that can provide complete line solutions ensures seamless integration and optimal performance matching among all devices.

6. Summary

Choosing the right SMT pick and place machine is a critical step for LED lighting companies to achieve efficient, high-quality production and stand out in a competitive market. Investing in a machine like the HW-A8, designed specifically for the LED industry, is not just about purchasing a machine; it injects powerful productivity and lasting competitiveness into your business.

It perfectly addresses the core challenges in LED production, including long board handling, high-speed placement, and component specificity and stands out with its excellent hardware configuration and optimized software system, becoming an ideal “growth engine” for LED lighting manufacturers.

If you are planning to upgrade or establish your LED production line and want to explore how the HW-A8 can elevate your capacity to a new level, please contact our expert team immediately. We will provide you with detailed technical consulting, on-site demonstrations, and customized solutions.