Measures to Reduce Misplacement by Pick and Place Machines

Reducing misplacement by pick and place machines requires a comprehensive optimization across multiple aspects, such as equipment maintenance, parameter settings, operational standards, and quality control. Below are specific measures:

1. Equipment Calibration and Maintenance

- Mechanical Structure Calibration

- Regularly calibrate the XYZ axis drive system using professional tools to ensure motion trajectory accuracy (especially due to mechanical wear from long-term use).

- Check and adjust PCB clamping parameters to prevent large PCBs from shifting during high-speed movement.

- Vision System Optimization

- Clean the lens and mirrors to avoid dust affecting the light source intensity and gray level recognition.

- Adjust camera focal length, angle, and light brightness to ensure component recognition accuracy.

- Maintenance of Nozzles and Vacuum System

- Regularly check for wear on nozzles and promptly replace deformed or clogged nozzles.

- Maintain stable vacuum system pressure to ensure appropriate adhesion (insufficient pressure can lead to floating components, while excessive pressure may damage components).

2. Feeder System Management

- Programming and Feeder Inspection

- After programming, have dedicated personnel verify that the feeder frames’ weight values match the programming table to avoid parameter misalignment.

- Confirm that tray values correspond with settings before loading belt feeders to prevent component type confusion.

- Component Parameter Settings

- Accurately set component thickness, PCB thickness, and support pin heights (e.g., overly thin PCBs or insufficiently raised support pins can lead to floating components).

- Select dedicated nozzles for irregular components, and set appropriate rotation angles and mounting directions in the program.

3. Operating Standards and Training

- Standardized Operational Procedures

- Check PCB flatness, ensuring the surface has no scratches or warps (warping should be controlled within ±0.5mm) before operation.

- Conduct manual or AOI inspection after the first component placement to confirm accuracy before mass production.

- Employee Skill Enhancement

- Train operators to recognize anomalies (such as feeder belt breaks or incorrect component orientation) and to handle basic troubleshooting (e.g., restarting feeders, correcting component orientation).

- Emphasize operational focus, monitoring equipment status with “active eyes, ears, and hands”.

4. Quality Control and Feedback

- Process Monitoring

- Conduct spot checks on placement positions during production; if discrepancies are found, immediately halt operations for investigation (e.g., check nozzle air pressure and component parameters).

- Establish a pre-solder inspection station using AOI equipment to detect missed placements or misalignments.

- Data Traceability and Optimization

- Record types of misplacement failures (such as floating components or misalignments) and their frequency to optimize equipment parameters or maintenance plans accordingly.

- Regularly analyze component quality data to eliminate materials that exceed dimensional tolerances or have bent leads.

5. Environmental and Auxiliary Measures

- Environmental Control

- Maintain workshop temperature at 25±3℃ and humidity at 40-60% to reduce the impact of temperature and humidity fluctuations on components and PCBs.

- Isolate vibration sources (such as large equipment) to avoid high-frequency vibrations causing placement shifts.

- Solder Paste and PCB Management

- Use high-viscosity solder paste and strictly control the usage period (usually within 72 hours after opening) to prevent flux inactivation causing component displacement.

- Store PCBs in moisture-proof boxes to avoid moisture absorption and warping.

Through the above multidimensional measures, the probability of misplacement by pick and place machines can be systematically reduced. In practical applications, detailed operations should be tailored according to specific equipment models (such as Siemens, Panasonic) and maintenance manuals, while continuously improving processes based on production data.

SMT pick and place machine recommendation

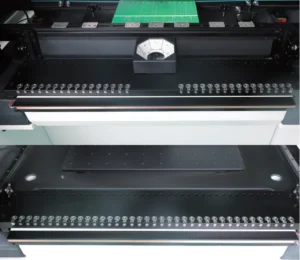

HW-S5 High-precision Automatic Pick-and-place Machine

Dual-arm combined placement enables the fastest placement speed of 84,000 CPH (under our optimal conditions).

HW-F5 High-precision Automatic Pick-and-place Machine

High-Efficiency Integrated Placement Head Configuration (Quick and Easy Setup)

Peak Performance: 42,000 CPH (Under Optimal Conditions)

HW-A8 Automatic Pick-and-place Machine for LED

Discover the high-performance HW-A8 SMT placement machine featuring 8 industrial vision cameras, Panasonic servo drives, and granite stability platform. Achieve ±0.05mm accuracy with 40K CPH speed for LED strips, bulbs, drivers & more. Professional-grade SMT solution with 360° placement capability.