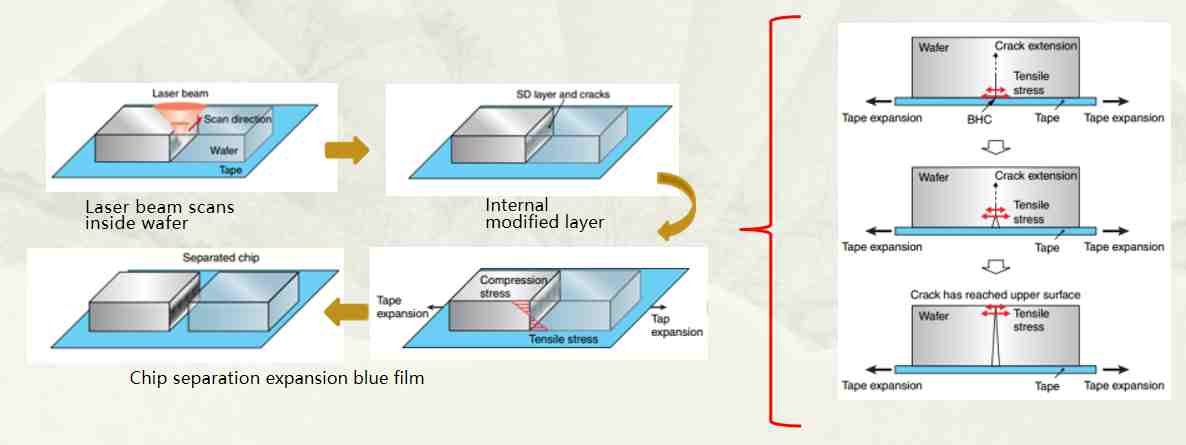

Laser internal modification cutting is to focus the infrared laser beam inside the wafer and form an internal ” The wafer is cut into individual chips by applying external force to the wafer .

Based on the mature LED dicing machine platform with higher precision and higher efficiency Prepare DSI – MC -9201 .

| Serial number | Device Name | Country of origin | Model | Quantity | Functions and parameters |

| 1 | Laser | China | U- fast | 1 | 3.0W@50KHZ;3.5W@100KHZ (light outlet) 50~200 KHZ adjustable |

| 1 | X/Y linear work tower | Self-made | 400*600 XY | 1 | 1) Stroke: 400X 600 mm 2) Resolution: Y= 0.1 μm; X=0.5um 3) Y repeat positioning accuracy: <=1μm (see Appendix 1) 4) X straightness: 1 um / 300 mm (see Appendix 2) |

| 2 | DD Motor and Driver | Import | / | 1 | 1) Maximum speed: 2.4rps 2) Rated speed: 2.0 rps 3) Encoder resolution: 26214400 p/ rev 4) Installation surface flatness: less than 10 um |

| 3 | CCD | Outsourcing | / | 4 | 1) Wide Angle 500W 2) Size and angle correction 1.3 million pixels; 3) Focus 300,000 pixels 4) High pixel telecentric lens |

| 4 | Z- axis | Import | / | 2 | 1) 0-8mm range 2) Repeat positioning accuracy: +/-1 um |

2. DRA cutting depth compatibility and improved stability The new sensor is more compatible with MINI film sources and can measure thinner products, improving tracking Improve the system’s adaptability to the product and improve cutting depth stability.

2. DRA cutting depth compatibility and improved stability The new sensor is more compatible with MINI film sources and can measure thinner products, improving tracking Improve the system’s adaptability to the product and improve cutting depth stability. HL-C2 :Movement resolution: approx. ±5μm Measuring thickness: 80um or more

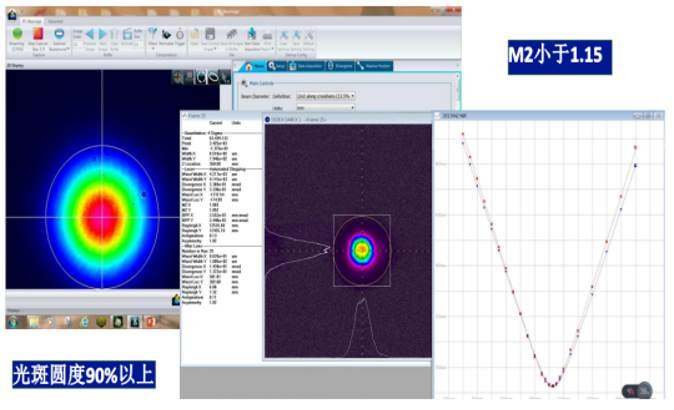

HL-C2 :Movement resolution: approx. ±5μm Measuring thickness: 80um or more LK-H008W (New) :Movement resolution: approx. ±1μm Measuring thickness: 30um or more3. Independent intellectual property rights dedicated laser By optimizing and improving the laser, Independently develop competitive lasers, Improve the quality of laser cutting LED wafers.

LK-H008W (New) :Movement resolution: approx. ±1μm Measuring thickness: 30um or more3. Independent intellectual property rights dedicated laser By optimizing and improving the laser, Independently develop competitive lasers, Improve the quality of laser cutting LED wafers.

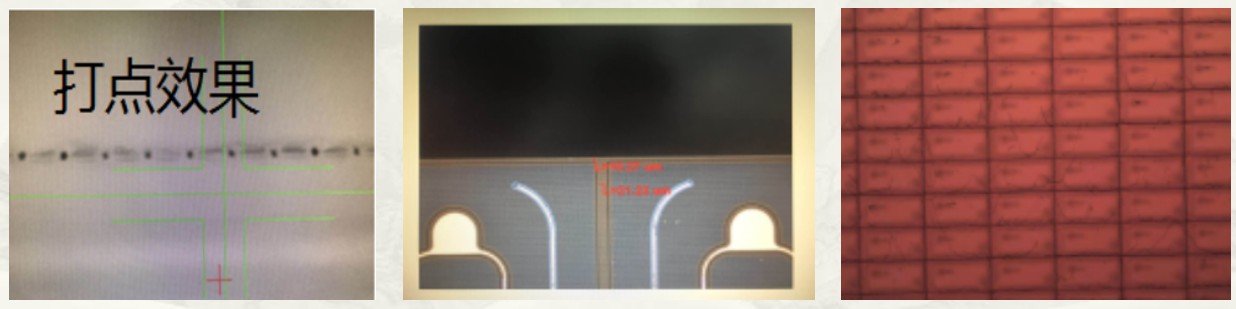

4. Improved alarm failure and improved stability Through continuous optimization, the alarm rate can be controlled within 1%~5%. That is, when producing 100 pieces, the machine will only alarm 1 to 5 times.5. New Vision: Equipped with three different bands of backlight sources, it has wider compatibility and automatic visual recognition and positioning.6. Main data Appearance yield: greater than or equal to 99.5% Electrical yield: industry-leading level efficiency : 30 Product size : 9*27 mil The production capacity of four-inch wafers is ≥ 7500 wafers / month, and the production capacity of six-inch wafers is ≥ 5000 wafers / month . Stability: Machine mobility ≥ 96% .7 Since the development of the equipment, many technical difficulties have been overcome, and many technologies are the first in the industry . And many patents have been applied for.

4. Improved alarm failure and improved stability Through continuous optimization, the alarm rate can be controlled within 1%~5%. That is, when producing 100 pieces, the machine will only alarm 1 to 5 times.5. New Vision: Equipped with three different bands of backlight sources, it has wider compatibility and automatic visual recognition and positioning.6. Main data Appearance yield: greater than or equal to 99.5% Electrical yield: industry-leading level efficiency : 30 Product size : 9*27 mil The production capacity of four-inch wafers is ≥ 7500 wafers / month, and the production capacity of six-inch wafers is ≥ 5000 wafers / month . Stability: Machine mobility ≥ 96% .7 Since the development of the equipment, many technical difficulties have been overcome, and many technologies are the first in the industry . And many patents have been applied for.

| 1 | Power requirements | 220V/single phase/50 HZ /16A; Power grid fluctuation: <5% The power plug of the device is a standard three-flat plug |

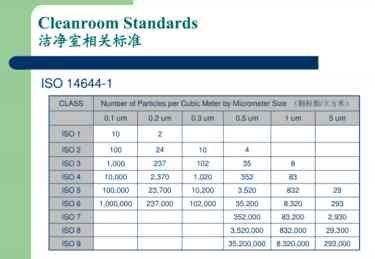

| 2 | Ambient temperature | 22~26℃; Temperature variation ±1℃ |

| 3 | Environment humidity | 40~70% No condensation |

| 4 | Compressed air | 0.6~0.7Mpa, equipment interface pipe diameter p12 mm |

| 5 | Environmental vibration requirements | Foundation amplitude <5μm Vibration acceleration <0.05G |

| 6 | Situations to avoid | ● Places with lots of garbage, dust, and oil mist; ● Places with lots of vibration and impact; ● Places where medicines and flammable and explosive materials can be touched; ● Locations near high-frequency interference sources; ● Places where the temperature changes rapidly; ● In CO2, NOX In environments with high concentrations of SOX, etc. |

Rm3A08 (4th Floor) Block D, Huashengtai Technology Park, No.36 Hangkong Road, Baoan District, Shenzhen City, China

© 2026 All Rights Reserved.