Smartphone SMT Machie Assembly line

I. Smartphone SMT Core Equipment Configuration List

| Categoria di apparecchiatura | Parametri chiave |

|---|---|

| Miscelatore di pasta saldante | Viscosity intelligent adjustment (10-200 Pa·s), mixing time ≤ 3 minutes, compatible with lead-free solder paste |

| Caricatore SMT | Dual-track automatic loading, compatible with board-less edge PCBs, speed ≥ 800 boards/hour |

| Stampante per pasta saldante | Stampa in ambiente azotato, precisione ±15μm, supporta BGA a passo 0,3 mm |

| Macchina SPI | 3D laser inspection, speed 40 cm²/s, AI automatic optimization of printing parameters |

| Macchina pick and place | Refurbished second-hand equipment, accuracy ±25μm, theoretical capacity 107,370 CPH, supports 0201 components. Hightlywin’s HW-A6L e HW-S5 Pick-and-Place Machines can also achieve 84,000 CPH. |

| Sistema di alimentazione a microcomponenti | Dedicated vibratory feeder for 0201 components, RFID intelligent material rack management |

| Macchina di riflusso | 12 temperature zones with nitrogen protection, oxygen content < 100 ppm, supports double-sided soldering process |

| Macchina AOI | Risoluzione ottica 10μm, modulo X-Ray integrato (opzionale) |

| Macchina di ispezione a raggi X | 5μm resolution, BGA void rate detection < 3% |

| Selective Wave Soldering | Precise spraying of flux, soldering accuracy ±0.1mm, supports THT/SMT hybrid processes |

| Macchina dosatrice di precisione | Dispensing accuracy ±0.01ml, supports underfill and conformal coating spraying |

| Macchina per la marcatura laser | Precisione di marcatura di 20μm, supporta la tracciabilità del codice QR e la marcatura del numero di lotto |

| Docking station | Dual-track buffer capacity 80 pieces, ±1℃ temperature control, compatible with AGV docking |

| Scaricatore SMT | Automatic sorting + defect tracking, compatible with board-less edge PCBs |

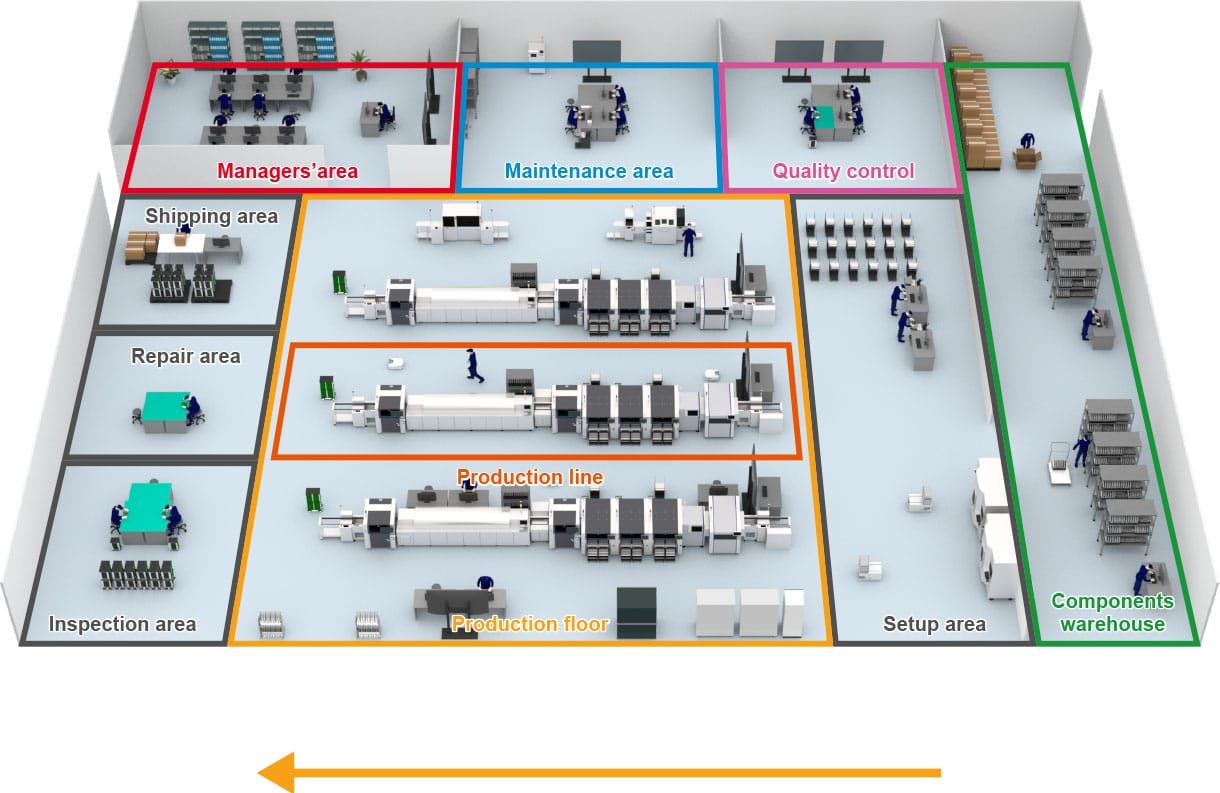

II.Smartphone SMT Machie Production Line Layout and Capacity Planning

1. Equipment Layout

[Intelligent Dual-Track Production Line Layout]

Solder Paste Mixing Area → Loader → Printer → SPI → Connecting Station → Pick-and-Place Machine (3 refurbished NXT)

↑↓

Selective Wave Soldering ← X-Ray Inspection ← Reflow Soldering ← Dispensing Machine

↓

AOI → Laser Marking → Unloader

Smartphone SMT Machine Assembly line Design Advantages:

- Dual-track independent operation supports simultaneous production of smartphone motherboards (Track A) and IoT modules (Track B).

- Dedicated line for micro components with CL Feeders system to reduce changeover time.

2. Smartphone SMT Equitment Assembly line Capacity Calculation

| Metrics | Parametri |

|---|---|

| Velocità di posizionamento teorica | 107.370 CPH (NXT III×3) |

| Capacità effettiva (OEE 78%) | Single shift (8h) output 41,000 motherboards |

| Tempo di transizione | ≤25 minutes (magnetic steel stencil + modular nozzles) |

| Velocità di trasmissione completa | ≥98.5% (SPI + AOI + X-Ray triple inspection) |

Supporto per processi speciali

Board-less edge PCB production:

- Customized vacuum suction cup fixtures (reference QT company solution).

- Added visual positioning compensation system, compensation accuracy ±0.05mm.

- Quick changeover system: 15 seconds to switch between different PCB models.

Compatible design for mixed boards:

- Uses dual-track mounting system, allowing simultaneous production of front and back panels.

- Automatic program recognition of panel alignment direction (reference G100 panel design).

III. Cell Phone SMT Production line Cost Optimization and Value-Added Services

1. Second-hand Equipment Guarantee Plan

- Refurbishment Standards: Replacement of key components (servo motors/rails), precision calibrated to 90% of factory specs.

- Service Commitment: MTTR ≤ 2 hours, spare parts inventory covering the Yangtze River Delta region.

2. Hybrid Process Support

Double-sided SMT + Wave Soldering Process:

Back side printing → Pick-and-Place → Reflow Soldering → Flip → Front side printing → Pick-and-Place → Reflow Soldering → Selective Wave Soldering (insertion components).

Conformal Coating: Dispensing machine integrated with conformal coating spraying module, compliant with IPC-CC-830 standards.

3. Intelligent Management System

- MES Integration: Real-time uploading of equipment data (printing parameters/oven temperature curve/inspection results).

- Predictive Maintenance: Vibration sensors + thermal imaging monitoring, fault alert accuracy ≥ 85%.

IV. Smartphone SMT Machine Supplier Cooperation Terms

| Terms Category | Specifics |

|---|---|

| Payment Method | 50% advance payment + 50% upon delivery |

| Formazione tecnica | Free provision of “SMT Equipment Standard Operating Manual” + On-site engineers for 7 days |

| Upgrade Reserved | Pick-and-place machine reserved for 5G module interface, supports wireless communication with AGV systems (compatible with Hermes 9852 standard) |

V. Risk Control and After-Sales Guarantee

| Risk Item | Response Measures |

|---|---|

| High rejection rate for micro components | Supply system offers 3 months of consumables package, if rejection rate > 0.3%, upgrade to a vibratory feeder for free. |

| Environmental Assessment Risk | Provide emissions treatment equipment environmental assessment report (activated carbon + catalytic combustion compliant with GB16297-1996). |

For additional information, please contact Highlywin to obtain:

- Second-hand equipment refurbishment inspection report (including precision calibration data).

- 3D simulation of dual-track production layout.

- Hybrid process validation cases (smartphone motherboards + automotive electronic modules).

This solution balances cost and quality; second-hand pick-and-place equipment can reduce initial investment, while the intelligent detection system ensures compliance with throughput rates. It is recommended that customers prioritize the layout of pick-and-place machines and SPI inspection stations while applying for environmental certification simultaneously.