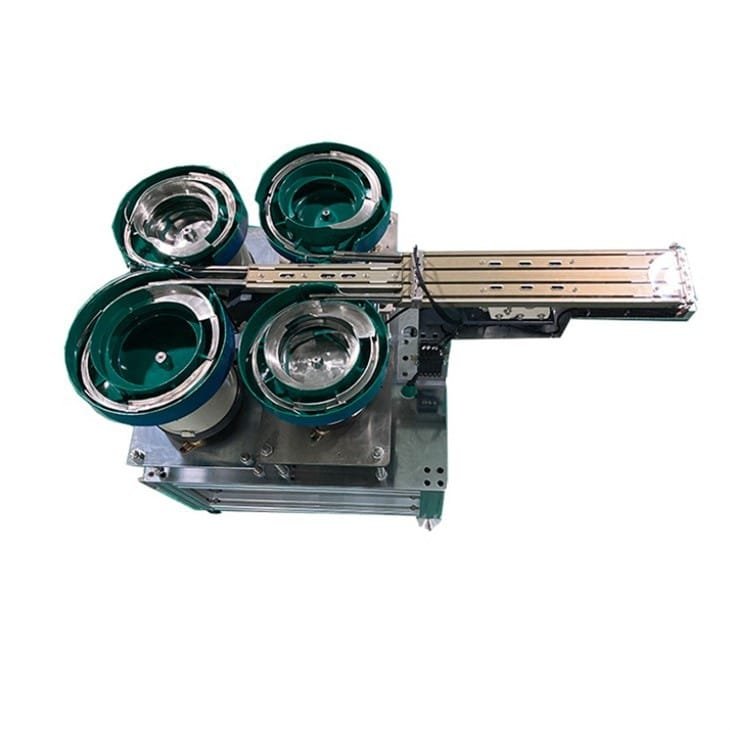

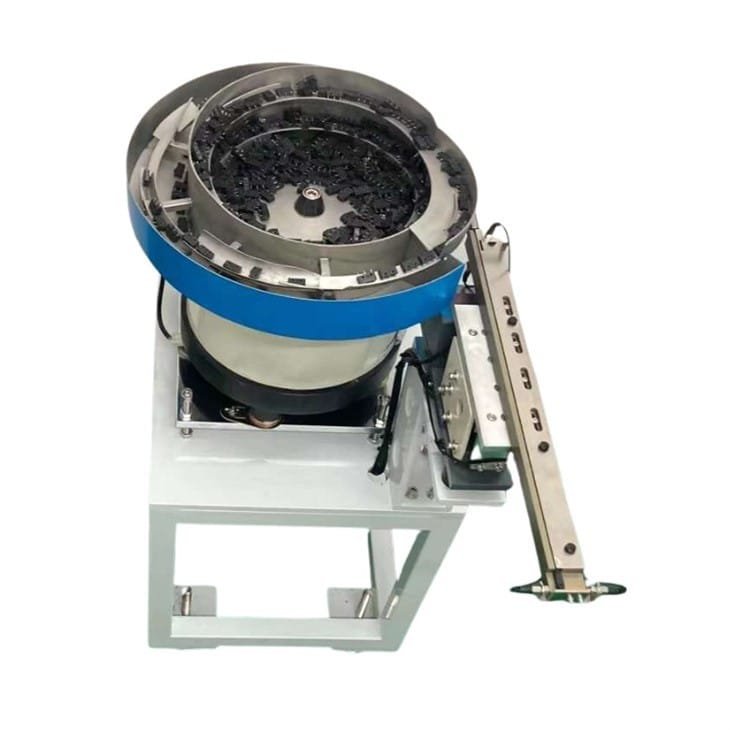

The vibratory bowl feeder is used for the SMT mounter/insertion machine, feeding bulk components such as terminal/ safety capacitor/ switch/ transformer/odd form components. Compatible with the brands machines of Panasonic, Juki, Fuji, ASM, Universal, etc., with height mechanical matching and communication to the machine.

Bowl feeders can be a flexible form of parts feeding to handle very small parts such as a pill or components. Although bowl feeders take up very little space, they can arrange, select, feed, and sort parts in a very cost-effective way. The effectiveness of a bowl feeder is measured by its output rate, part orientation, and the space it fills on the production floor. Bowl feeders can have an output rate as high as 1600 parts per minute.

For more customization details, message us.

Rm3A08 (4th Floor) Block D, Huashengtai Technology Park, No.36 Hangkong Road, Baoan District, Shenzhen City, China

© 2026 All Rights Reserved.