Рынок оборудования для соединения проводов — это сегмент в полупроводниковой и электронной промышленности, который фокусируется на машинах, используемых для создания электрических соединений в полупроводниковых приборах, в частности, с помощью процесса, называемого соединением проводов. Этот процесс включает соединение тонких проводов между электронными компонентами и подложками, что имеет решающее значение для сборки микросхем.

Рынок оборудования для склеивания проволоки Рост рынка и тенденции

- Мировой рынок оборудования для сварки проводов переживает значительный рост в связи с растущим спросом на современные электронные устройства и миниатюризацией электронных компонентов.

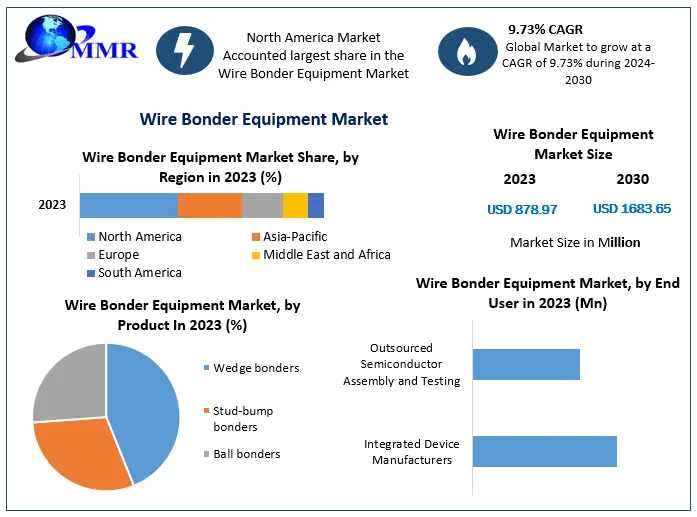

- Прогнозируется, что объем рынка существенно расширится: по оценкам, к 2030 году он превысит 1 624,70 млн долларов США по сравнению с 786,14 млн долларов США в 2022 году, а среднегодовой темп прироста (CAGR) в период с 2023 по 2030 год составит 9,8%.

- Согласно другому прогнозу, среднегодовой темп роста рынка составит 5,5% в период с 2023 по 2030 год, а ожидаемый объем к концу периода составит 1381,21 млн долларов США, что подчеркивает устойчивую траекторию роста.

- Развитие отрасли обусловлено потребностью в более совершенном оборудовании для упаковки полупроводников в различных секторах, таких как электроника, автомобилестроение и промышленное применение.

Причины роста рынка оборудования для сварки проволоки

Ключевые факторы роста рынка оборудования для сварки проволоки многогранны и включают в себя:

- Растущий спрос на современные электронные устройства: Глобальный переход к более сложным электронным устройствам, включая смартфоны, носимые устройства и устройства Интернета вещей, требует использования современных полупроводниковых компонентов, что, в свою очередь, обуславливает потребность в эффективных машинах для соединения проводов. [2][6]

- Миниатюризация электронных компонентов: По мере развития технологий электронные компоненты становятся меньше и более плотно упакованными, требуя точного и миниатюрного соединения проводов для подключения. Эта тенденция особенно очевидна в таких секторах, как технология 5G, где миниатюрные компоненты имеют важное значение. [2][5]

- Внедрение технологии 5G: Внедрение сетей 5G привело к увеличению спроса на высокопроизводительные полупроводники, сборка которых основана на проволочном соединении. [2]

- Рост полупроводниковой промышленности: Быстрый рост полупроводниковой промышленности, вызванный расширением цифровой экономики, создает значительный рынок для оборудования для соединения проводов. [6][9]

- Передовые технологии упаковки: Разработка и внедрение передовых технологий упаковки, таких как «система в корпусе» (SiP) и «упаковка на уровне пластины» (WLP), требуют специализированного оборудования для соединения проводов. [1][6]

- Переход на электромобили (ЭМ) и ADAS: Переход автомобильной промышленности на электромобили и интеграция усовершенствованных систем помощи водителю (ADAS) требуют надежных и прочных полупроводниковых узлов, что обуславливает спрос на оборудование для соединения проводов. [4]

- Инвестиции в НИОКР: Крупные игроки вкладывают значительные средства в исследования и разработки для создания современных устройств для соединения проводов, способных решать сложные задачи по соединению, такие как соединение лент для гибридных схем и автомобильных силовых модулей. [7]

- Технологические достижения: Усовершенствования в технологиях соединения проводов, включая разработку новых машин для соединения, которые обеспечивают более высокую точность и скорость, способствуют росту рынка. [1][6]

- Расширение промышленности и телекоммуникаций: Рост в секторах производства, энергетики и телекоммуникаций также открывает возможности для оборудования для сварки проводов из-за растущего спроса на надежные электронные компоненты. [4]

В совокупности эти факторы способствуют устойчивому росту рынка оборудования для сварки проволоки с упором на инновации, автоматизацию и удовлетворение потребностей все более цифрового мира.

Производитель оборудования для сварки проволоки

Тег:Рынок оборудования для сварки проволоки