Many entrepreneurs entering the SMT (Surface Mount Technology) industry often find themselves in a dilemma regarding equipment selection and funding. While striving for perfection, budget constraints may hinder achieving the desired outcomes. Consequently, they consider opting for cost-effective equipment but may lack knowledge about the SMT equipment industry, fearing pitfalls and scams. Today, we’ll discuss how novices can successfully purchase SMT equipment and avoid common traps. Here is a detailed guide to help you make a wiser purchasing decision:

1. Clearly Define Your Needs

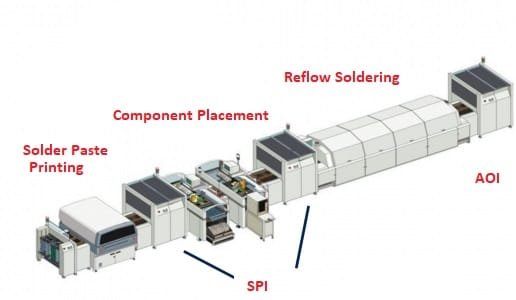

First, determine whether you want to buy used or new equipment. Identifying your goals and requirements is crucial, which includes SMT production needs, process requirements, production scale, product types, capacity, PCB dimensions, and relevant components. Gathering this information will aid you in selecting the most suitable SMT equipment. Generally, an SMT production line includes the following equipment: board loader, solder paste printer, connector table, 3D SPI, pick and place machines (medium-speed, high-speed, etc.), PCBA insertion machine, vacuum reflow oven or wave soldering machine, 3D AOI, X-ray, and board unloader. These items constitute a complete SMT production line, and some may be selected based on actual needs.

2. Tips for Buying Used vs. New Equipment

SMT equipment brands and prices vary significantly. Here are some considerations for purchasing used versus new SMT equipment:

Buying Used Equipment

For those looking to buy high-value second-hand equipment due to budget constraints, it can greatly save on expenses. However, risks are involved, as unexpected issues may arise, and maintenance costs can exceed those of new equipment. To mitigate this risk, request relevant documentation from the supplier to ensure improved purchasing safety. Key points to consider when buying used equipment include:

- Check the official ID label for the production date and the last operational time of the equipment.

- Inspect for signs of rust, paint peeling, or broken acrylic parts on the equipment.

- Determine if the used equipment is still under warranty; if not, at least ensure a six-month warranty from the supplier.

- Review any service logs from the previous owner to understand maintenance frequency.

- Investigate the supplier’s reputation and reliability by researching online and asking colleagues for feedback.

- Ensure software is updated to the latest version and check for any obsolescence.

Additionally, consider the manufacturer’s reputation, performance, precision, and speed. It’s advisable to request samples for testing. Price and delivery time are also critical factors.

Choosing New Equipment

For financially robust entrepreneurs looking to purchase new SMT equipment, consider the following:

- Conduct market research to gather information on prices, quality, reliability, and after-sales service of different brands and suppliers before making a purchase plan.

- Assess if the equipment meets the technical needs for your products, comparing various brands and models in terms of speed, precision, PCB size handling, component types, and quantities.

- Consider future requirements and production plans, such as potential increases in production scale, introduction of new products, and the ability to upgrade technology with advancements.

- Confirm that the after-sales service of your chosen supplier meets your requirements, including technical support for repairs, maintenance, and spare parts supply.

- Finally, read all contract terms carefully once a supplier is selected to ensure accuracy regarding equipment brand/model, pricing, payment methods, delivery schedules, warranty terms, and technical support to avoid potential risks and after-sales issues in the future.

Final Recommendations

If you are a novice owner in the SMT equipment market, whether you choose new or used equipment, consider hiring an experienced SMT engineer to assist you in assessing your production needs and making more efficient purchases. If you’re still hesitant, consider leasing equipment first and purchasing it once you are confident in its performance.

If you have further concerns, feel free to contact us for a customized cost-effective solution tailored to your needs.