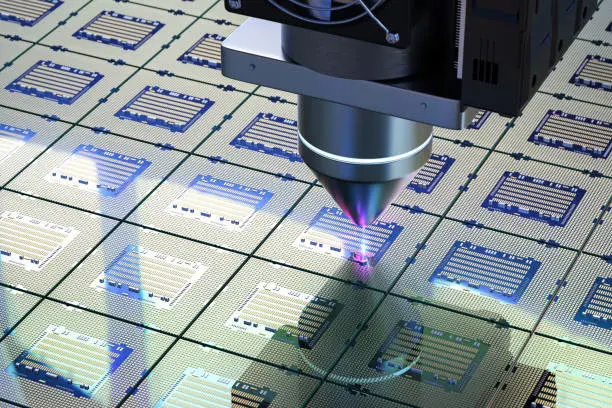

Wire Bonding Machines in the Semiconductor Industry

Wire bonding machines are specialized equipment used in the semiconductor industry to create electrical connections between an integrated circuit (IC) or other semiconductor devices and its packaging. These machines are essential in the final stages of semiconductor device fabrication, ensuring that the delicate electronic components are properly connected and can function as intended.

Types of Wire Bonding Machines

Ball Bonding Machines

- These machines use a capillary to form a ball at the end of the wire and then bond it to the die and the substrate.

- Ball bonding is the most common type of wire bonding, known for its speed and flexibility.

Wedge Bonding Machines

- These machines use a wedge tool to form a bond between the wire and the substrate.

- Wedge bonding is typically used for aluminum wires and is preferred in high-power applications.

Key Components

Capillary or Wedge Tool

- The capillary or wedge tool is responsible for forming the bond between the wire and the substrate.

- Capillaries are used in ball bonding, while wedge tools are used in wedge bonding.

Wire Spool

- The wire spool holds the bonding wire, which is typically made of gold, aluminum, copper, or silver.

- The wire diameter can range from under 10 μm to several hundred micrometers, depending on the application.

Microcontroller or Control System

- The control system manages the precise movements of the bonding tool and the wire feed.

- It ensures that the bonding process is accurate and consistent, often using sensors to monitor the wire tension and alignment.

Motor and Drive System

- Motors, such as stepper motors or servo motors, drive the bonding tool and the wire feed.

- The drive system ensures smooth and controlled movement, which is crucial for high-quality bonding.

Система технического зрения

- Many modern wire bonding machines are equipped with vision systems to align the bonding tool with the bond pads on the die and substrate.

- This improves the accuracy and reliability of the bonding process, especially in high-density and fine-pitch applications.

Wire Bonding Machines Operation Process

Preparation

- The IC die and the substrate are prepared and positioned in the bonding machine.

- The wire spool is loaded, and the bonding tool is calibrated.

Bonding

- The bonding tool forms a ball at the end of the wire (for ball bonding) or a wedge (for wedge bonding).

- The tool then places the wire on the bond pad of the die and applies pressure and heat to form a strong bond.

- The wire is fed to the next bond pad, and the process is repeated until all connections are made.

Post-Bonding

- The completed IC is inspected for quality and reliability.

- Any defective bonds are identified and can be reworked if necessary.

Advantages

Экономическая эффективность

Wire bonding is generally considered the most cost-effective interconnect technology, especially for high-volume production.

Гибкость

Wire bonding machines can handle a wide range of wire materials and diameters, making them versatile for different applications.

High Frequency Performance

Wire bonding can be used in devices operating at frequencies above 100 GHz, which is critical for advanced semiconductor applications.

Automated Process

Modern wire bonding machines are highly automated, reducing the need for manual intervention and improving production efficiency.

Wire Bonding Machines Applications

Semiconductor Packaging

Wire bonding is the primary method for connecting ICs to their packaging, essential for the assembly of most semiconductor devices.

Printed Circuit Boards (PCBs)

Wire bonding can also be used to connect ICs directly to PCBs, although this is less common.

Specialized Devices

Some specialized devices, such as those used in military and aerospace applications, also rely on wire bonding for their interconnections.

Challenges and Solutions

Bonding Quality

Ensuring high-quality bonds is crucial for the reliability of the final product. Advanced control systems and vision systems help improve bonding accuracy and consistency.

High-Density Interconnects

As devices become more complex, the density of bond pads increases. High-precision bonding tools and vision systems are used to address this challenge.

Material Compatibility

Different wire materials have different properties, and the bonding process must be adjusted accordingly. Modern machines can handle a variety of materials and provide optimal settings for each.

Hightliwy Wire Bonding Machines ODM

Enhanced Automation

Future developments in wire bonding machines focus on further enhancing automation, including the integration of artificial intelligence (AI) for real-time process optimization.

Improved Vision Systems

Advanced vision systems, such as those using machine learning algorithms, are being developed to improve alignment accuracy and reduce defects.

Миниатюризация

As electronic devices continue to shrink, wire bonding machines are designed to handle finer pitch and smaller bond pads.

Заключение

In summary, wire bonding machines are sophisticated tools that play a vital role in the semiconductor industry by creating reliable electrical connections between ICs and their packaging. They are characterized by their cost-effectiveness, flexibility, and ability to handle high-frequency applications, making them indispensable in modern electronics manufacturing.