Цели проектирования

To optimize equipment precision and stability for high-frequency circuit board production (supporting Wi-Fi 6E/7 protocols), compatible with 0402/0201 microcomponents and QFN packages, single board size ≤ 150 × 100 mm.

1. Core Equipment Configuration and Selection Strategy

| Категория оборудования | Основные технические параметры |

|---|---|

| Миксер для паяльной пасты | Lead-free solder paste, viscosity control ±5Pa·s, mixing time ≤2 minutes (including vacuum defoaming function). |

| Загрузчик SMT | Dual-track independent board feeding, compatible with thin boards (0.4mm thickness), speed ≥1200 boards/hour. |

| Принтер паяльной пасты | Nanocoating stencil technology, printing accuracy ±10μm, supports 0.25mm pitch BGA. |

| SPI Machine | 3D laser scanning + AI defect classification, detection speed 60 cm²/s, supports 0.08 mm² solder paste volume detection. |

| Выбери и размести | Used Fuji NXT III or HW-G5 high-speed machine, accuracy ±15μm (Cpk ≥1.67), supports irregular component picking. |

| Система подачи микрокомпонентов | Vibrating feeder + 8mm tape feeding, throw rate < 0.15% (0201 components). |

| Машина для растапливания | 14 temperature zones with nitrogen protection, maximum heating rate 4°C/s, supports low void soldering on high-frequency boards (void rate < 5%). |

| AOI машина | Multispectral detection (visible + infrared), defect recognition rate > 99%, supports cold soldering/standing tombstone/offset compound defect analysis. |

| Рентгеновская инспекционная машина | 3μm resolution, layered detection of BGA/QFN solder joints, supports 3D tomographic scanning. |

| Селективная пайка волной | Precise flux spray (±0.05ml), adjustable soldering angle (30°-60°), suitable for through-hole connector soldering. |

| Прецизионная дозирующая машина | Dual-valve piezoelectric jetting, dispensing speed 200 dots/second, supports bottom filling adhesives & conformal coating synchronous operation. |

| Лазерная маркировочная машина | UV laser marking, line width ≤15μm, supports MAC address/SN code burning. |

| Док-станция | Temperature control buffer module (±0.5°C), supports dual-track asynchronous transfer, AGV docking error ≤1mm. |

| Разгрузочное устройство SMT | Intelligent sorting system, automatically isolates defective products and generates MES traceability reports. |

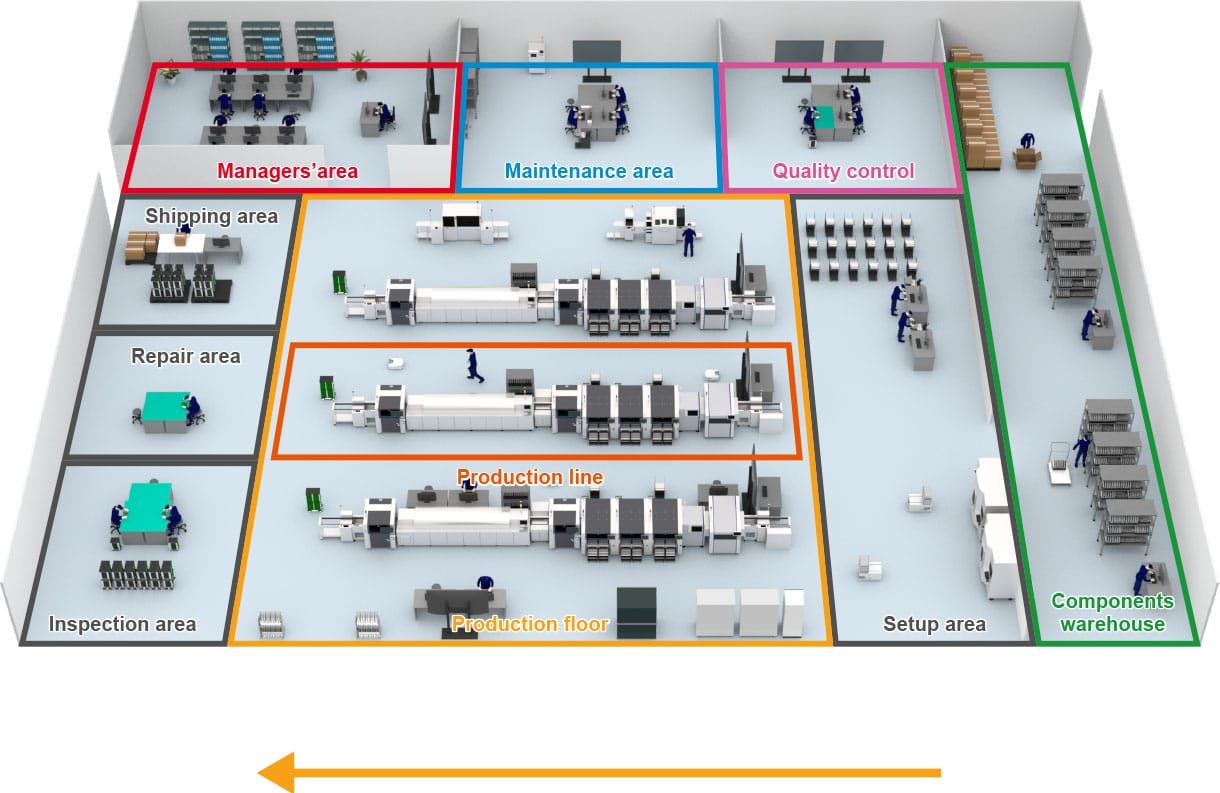

2. Production Line Layout and Logistics Design

1. High-Frequency Board Specialized Layout

[Production Line Flowchart] Loader → Printer → SPI → Junction Table → Pick and Place (NXT III×2) → Reflow Soldering → AOI → X-Ray ↓ Selective Wave Soldering ← Dispensing Machine ← Laser Marking ← Unloader

Core Optimization Points:

- Electrostatic Protection Zone: Ionizers (±3V balance) and anti-static curtains are configured from the printer to the reflow soldering area.

- Dedicated Micro Component Line: Feeding system directly connected to the pick and place machine, material station switch time < 10 seconds.

- Dual Track Asynchronous Control: Track A produces main control boards (6-layer), Track B produces RF modules (4-layer).

2. Модель потенциала и эффективности

| Индикатор | Параметр |

|---|---|

| Теоретическая скорость монтажа | 85,000 CPH (NXT III×2) |

| Actual Capacity (OEE 82%) | 32,000 main boards output per single shift (8 hours) |

| Время переключения | ≤18 minutes (magnetic steel stencil + quick material change cart) |

| Overall Pass Rate | ≥99.2% (triple interception using SPI + AOI + X-Ray) |

3. Special Process Support for High-Frequency Circuits

1. RF Module Production Requirements

- Soldering Control: Reflow soldering profile set with a slow ramp-up zone of 2°C/s (100-150°C) to reduce stress on the dielectric layer.

- Shielding Frame Assembly: The dispensing machine integrates a conductive glue spraying module, grounding impedance < 10 mΩ.

- Signal Integrity: X-Ray inspection for weld point height consistency (±8μm).

2. Hybrid Assembly Scheme

Main Flow: SMT mounting (0402 components) → Selective wave soldering (RJ45 interface) → Conformal coating (special for waterproof models) Secondary Flow: FPC soft board produced synchronously with customized fixtures (fixture switch time ≤ 5 minutes)

4. Cost Control and Risk Mitigation

1. Second-Hand Equipment Assurance Plan

- Refurbishment Standards: Full replacement of servo motors/screws, visual system upgraded to 10μm accuracy.

- After-Sales Commitment: 4-hour onsite response in the Yangtze River Delta, spare parts inventory coverage > 90%.

2. Domestic Replacement Strategy

| Equipment | Domestic Solution | Cost Reduction |

|---|---|---|

| Выбери и размести | HW-G5 high-speed machine (±20μm) | 38% |

| AOI | Matrix Technology VisionX | 45% |

| Дозирующая машина | Andar Intelligent AD-890 | 32% |

5. Supplier Cooperation Terms

| Условия | Details |

|---|---|

| Acceptance Criteria | Continuous 48-hour production test, CPK ≥ 1.67 (key positions of pick and place/AOI). |

| Способ оплаты | 40% advance payment + 30% shipment payment + 30% acceptance payment (including 3% quality assurance fund). |

| Техническое обучение | Provide “High-Frequency Board SMT Process Manual” + 5 days of on-site debugging (including electrostatic protection specialized training). |

Вложения

- High-Frequency Board Soldering Curve Template (including lead-free/lead-containing process parameters).

- Second-Hand Equipment Refurbishment Inspection Report (including MTBF ≥ 8000 hours certification).

- Hybrid Assembly Verification Cases (Main Control Board + RF Module produced on the same line).

This solution combines second-hand and domestic equipment to reduce initial investment by 30%. The triple inspection system ensures that the router mainboard pass rate meets requirements. It is recommended to prioritize verification of RF module soldering processes while simultaneously applying for IPC-6012DA Class 3 certification.