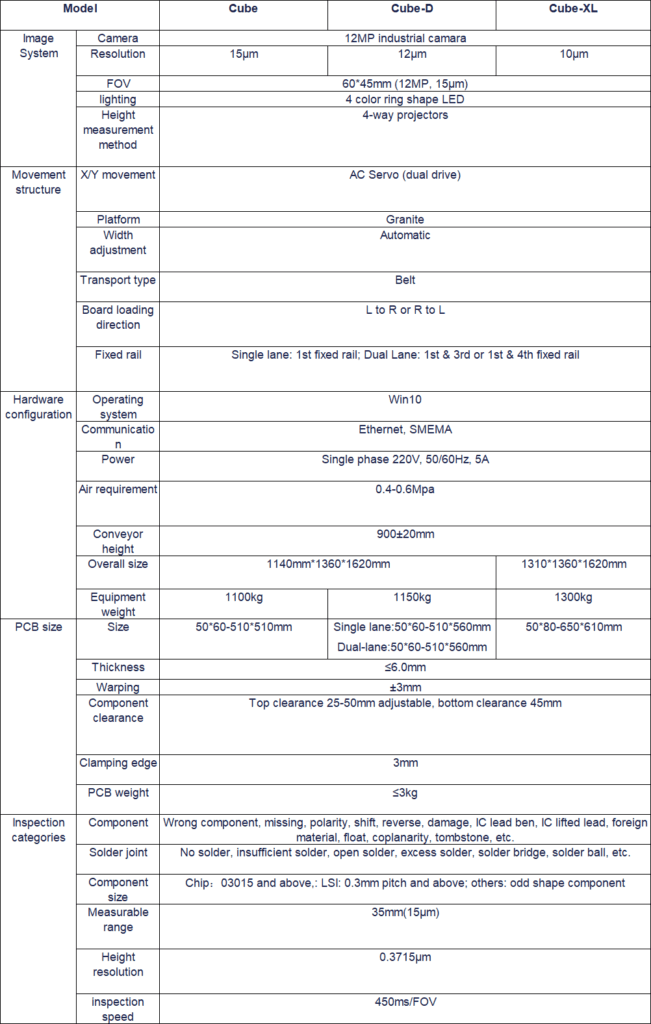

Model | Cube | Cube-D | Cube-XL | |

Image System | Camera | 12MP industrial camara | ||

Resolution | 15μm | 12μm | 10μm | |

FOV | 60*45mm (12MP, 15μm) | |||

lighting | 4 color ring shape LED | |||

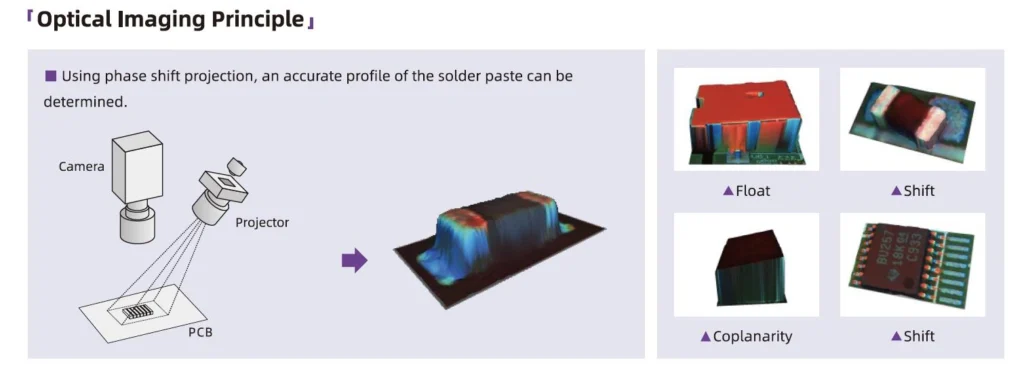

Height measurement method | 4-way projectors | |||

Movement structure | X/Y movement | AC Servo (dual drive) | ||

Platform | Granite | |||

Width adjustment | Automatic | |||

Transport type | Belt | |||

Board loading direction | L to R or R to L | |||

Fixed rail | Single lane: 1st fixed rail; Dual Lane: 1st & 3rd or 1st & 4th fixed rail | |||

Hardware configuration | Operating system | Win10 | ||

Communication | Ethernet, SMEMA | |||

Power | Single phase 220V, 50/60Hz, 5A | |||

Air requirement | 0.4-0.6Mpa | |||

Conveyor height | 900±20mm | |||

Overall size | 1140mm*1360*1620mm | 1310*1360*1620mm | ||

Equipment weight | 1100kg | 1150kg | 1300kg | |

PCB size | Size | 50*60-510*510mm | Single lane:50*60-510*560mm | 50*80-650*610mm |

Thickness | ≤6.0mm | |||

Warping | ±3mm | |||

Component clearance | Top clearance 25-50mm adjustable, bottom clearance 45mm | |||

Clamping edge | 3mm | |||

PCB weight | ≤3kg | |||

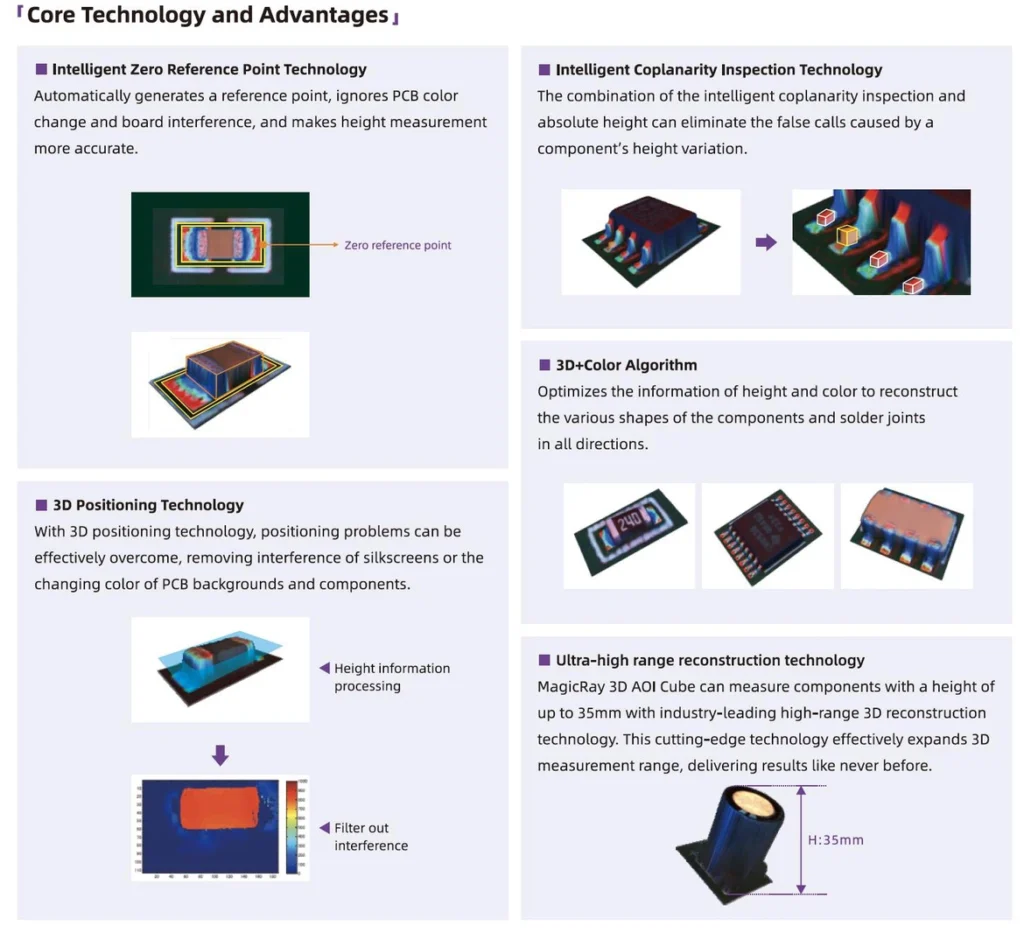

Inspection categories | Component | Wrong component, missing, polarity, shift, reverse, damage, IC lead ben, IC lifted lead, foreign material, float, coplanarity, tombstone, etc. | ||

Solder joint | No solder, insufficient solder, open solder, excess solder, solder bridge, solder ball, etc. | |||

Component size | Chip:03015 and above,: LSI: 0.3mm pitch and above; others: odd shape component | |||

Measurable range | 35mm(15μm) | |||

Height resolution | 0.3715μm | |||

inspection speed | 450ms/FOV | |||

Rm3A08 (4th Floor) Block D, Huashengtai Technology Park, No.36 Hangkong Road, Baoan District, Shenzhen City, China

© 2026 All Rights Reserved.