We have a full range of oven ranging from 8 to 12 zone, from nitrogen to hot air versions, please contact us to discuss your individual requirement.

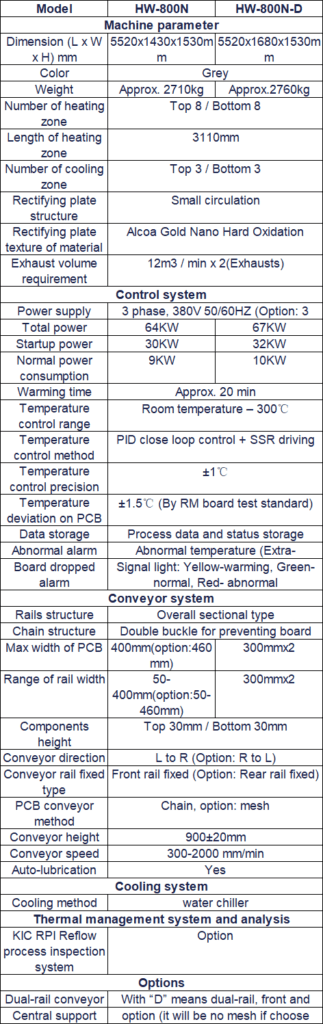

Model | HW-800N | HW-800N-D |

Machine parameter | ||

Dimension (L x W x H) mm | 5520x1430x1530mm | 5520x1680x1530mm |

Color | Grey | |

Weight | Approx. 2710kg | Approx.2760kg |

Number of heating zone | Top 8 / Bottom 8 | |

Length of heating zone | 3110mm | |

Number of cooling zone | Top 3 / Bottom 3 | |

Rectifying plate structure | Small circulation | |

Rectifying plate texture of material | Alcoa Gold Nano Hard Oxidation | |

Exhaust volume requirement | 12m3 / min x 2(Exhausts) | |

Control system | ||

Power supply | 3 phase, 380V 50/60HZ (Option: 3 phase, 220V 50/60HZ) | |

Total power | 64KW | 67KW |

Startup power | 30KW | 32KW |

Normal power consumption | 9KW | 10KW |

Warming time | Approx. 20 min | |

Temperature control range | Room temperature – 300℃ | |

Temperature control method | PID close loop control + SSR driving | |

Temperature control precision | ±1℃ | |

Temperature deviation on PCB | ±1.5℃ (By RM board test standard) | |

Data storage | Process data and status storage | |

Abnormal alarm | Abnormal temperature (Extra-high/Extra-low temperature after constant temperature) | |

Board dropped alarm | Signal light: Yellow-warming, Green-normal, Red- abnormal | |

Conveyor system | ||

Rails structure | Overall sectional type | |

Chain structure | Double buckle for preventing board jammed | |

Max width of PCB | 400mm(option:460mm) | 300mmx2 |

Range of rail width | 50-400mm(option:50-460mm) | 300mmx2 |

Components height | Top 30mm / Bottom 30mm | |

Conveyor direction | L to R (Option: R to L) | |

Conveyor rail fixed type | Front rail fixed (Option: Rear rail fixed) | |

PCB conveyor method | Chain, option: mesh | |

Conveyor height | 900±20mm | |

Conveyor speed | 300-2000 mm/min | |

Auto-lubrication | Yes | |

Cooling system | ||

Cooling method | water chiller | |

Thermal management system and analysis | ||

KIC RPI Reflow process inspection system | Option | |

Options | ||

Dual-rail conveyor | With “D” means dual-rail, front and rear rail fixed, 2 centrals adjustable | |

Central support | option (it will be no mesh if choose center support system) | |

Rm3A08 (4th Floor) Block D, Huashengtai Technology Park, No.36 Hangkong Road, Baoan District, Shenzhen City, China

© 2025 All Rights Reserved.