Peak Performance: 42,000 CPH (Under Optimal Conditions)

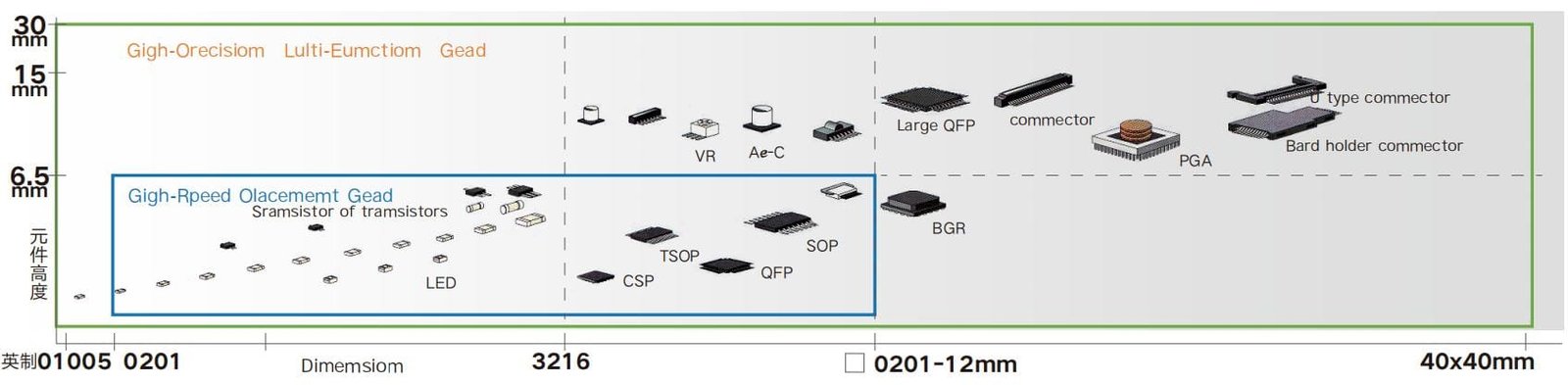

Component Compatibility: Supports tiny 0201 chips to large components up to 40mm × 40mm

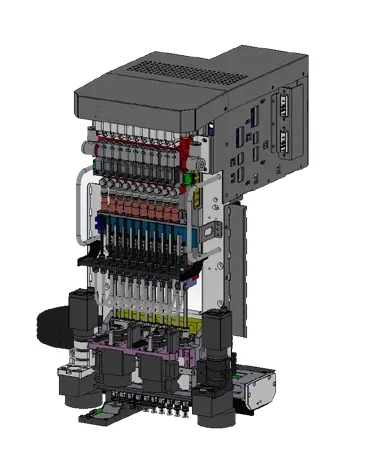

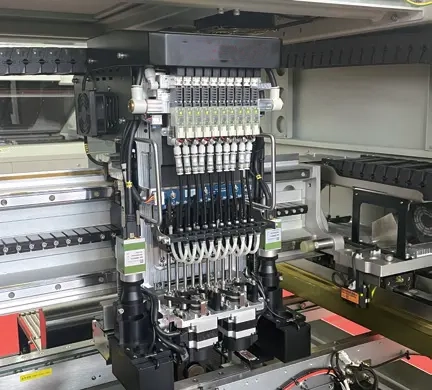

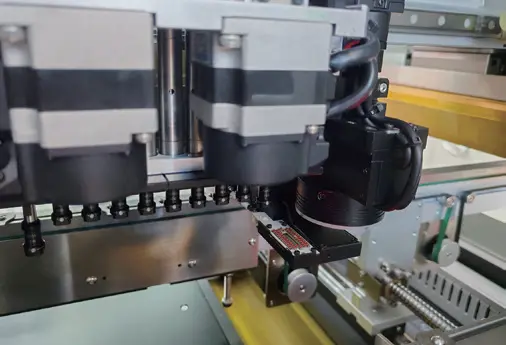

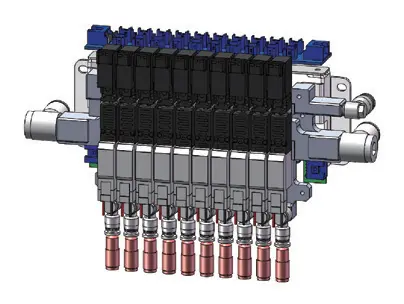

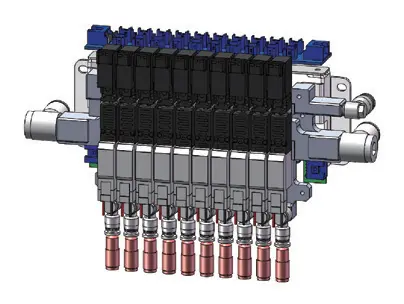

Equipped with a new lightweight 10-head high-speed placement head featuring an on-the-fly camera, capable of handling 0201 miniature components up to L12×W12×H6.5mm standard components.

The Z-axis of the placement head utilizes a high-precision linear motor, ensuring component placement accuracy within ±0.035mm while maintaining high-efficiency placement performance.

Equipped with the new 0624R high-precision placement head, featuring high-accuracy servo motor control on the R-axis. Capable of handling imperial 0201 miniature components up to L40×W40×H25mm large/irregular components, enabling high-speed, high-precision placement.

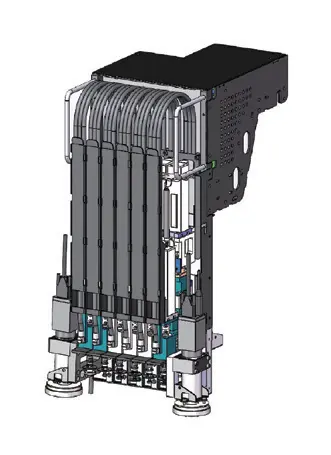

The XY-axis adopts an advanced dual linear motor system, a leading industry-standard configuration. Linear motors offer minimal wear, superior precision, and extended service life. The dual linear motor setup ensures higher production efficiency while maintaining exceptional machine stability.

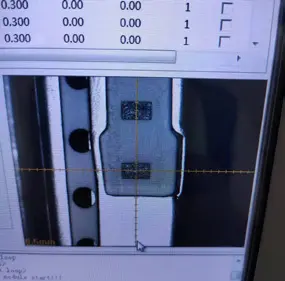

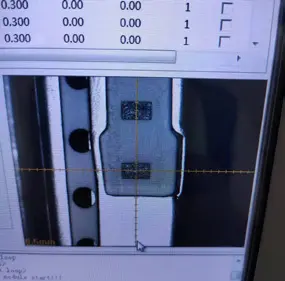

The new flying camera can perform recognition and correction for all CHP (Chip) components during high-speed placement, with a recognizable component size range of up to 12×12mm. It also supports component recognition for certain chip components and spherical components, enabling more efficient production.

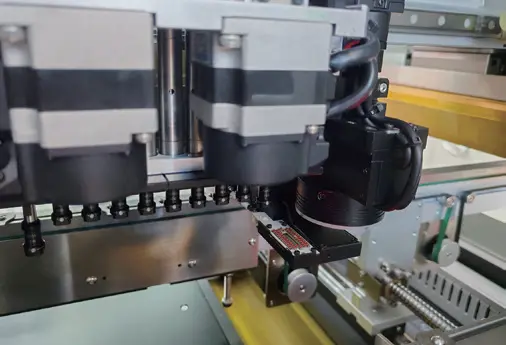

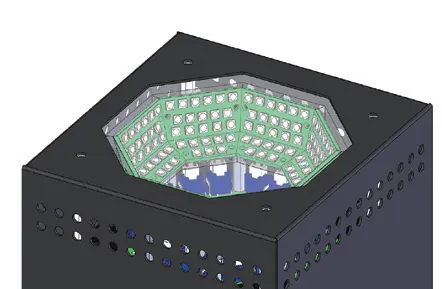

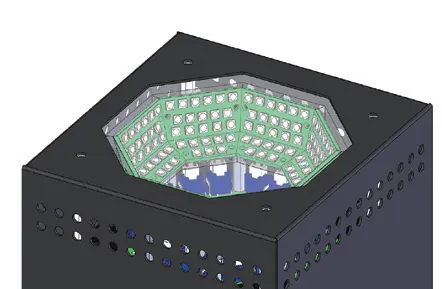

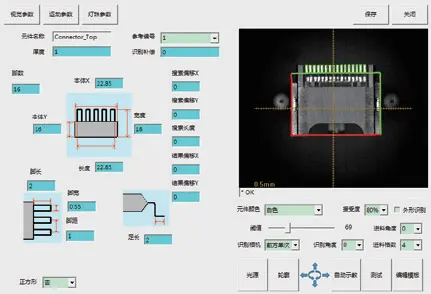

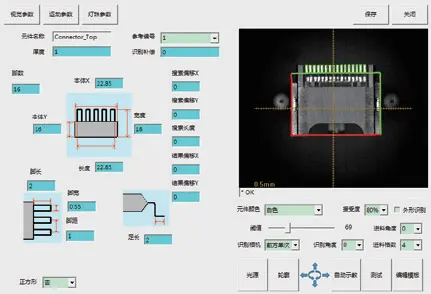

A newly independently designed light source controller, paired with imported high-resolution industrial cameras, achieves higher precision and faster response, enabling high-precision placement for various chips and irregular components.

The new flying camera can perform recognition and correction for all CHP (Chip) components during high-speed placement, with a recognizable component size range of up to 12×12mm. It also supports component recognition for certain chip components and spherical components, enabling more efficient production.

A newly independently designed light source controller, paired with imported high-resolution industrial cameras, achieves higher precision and faster response, enabling high-precision placement for various chips and irregular components.

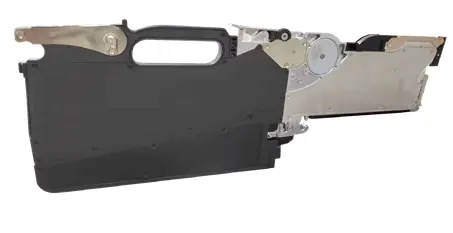

Our self-developed high-precision feeder ensures accurate feeding of 0201 micro components, supporting tape widths of 8/12/16/24/32/44/56/72/88mm.

The newly upgraded vibratory feeder delivers more stable vibration frequency, providing flexible feeding solutions for various tubular components.

The enhanced IC tray cabinet features servo-driven high-precision sliding rails, capable of storing 20 trays and supporting hot-swapping for uninterrupted production.

The newly designed ATC (Automatic Tool Changer) nozzle auto-changer can accommodate 40pcs of various nozzle types, enabling automatic switching between different nozzles based on production requirements.

Making device operation more convenient, smarter, and more flexible.

Scan QR codes to send data, allowing downstream equipment to automatically download programs and adjust conveyor width.

Pre-Pickup Self-Check: Automatically detects and confirms the optimal vacuum level before pickup.

Post-Pickup Verification: Validates successful component pickup via vacuum sensing, preventing mid-movement drops.

Automatically identifies and corrects the pickup position for tape-fed components using machine programming software.

Adjusts placement pressure and dwell time based on component characteristics and process requirements.

Scan QR codes to send data, allowing downstream equipment to automatically download programs and adjust conveyor width.

Pre-Pickup Self-Check: Automatically detects and confirms the optimal vacuum level before pickup.

Post-Pickup Verification: Validates successful component pickup via vacuum sensing, preventing mid-movement drops.

Automatically identifies and corrects the pickup position for tape-fed components using machine programming software.

Adjusts placement pressure and dwell time based on component characteristics and process requirements.

New smart digital centering algorithm supports one-click editing for non-standard/irregular components.

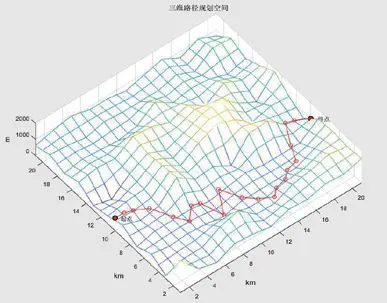

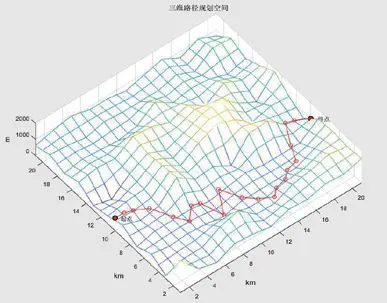

Integrates advanced algorithms (Ant Colony, Clustering Analysis, AI Deep Learning) to optimize pickup/placement paths and maximize equipment utilization.

One-click import of placement coordinates via text files, Excel, or other compatible formats.

Networked Component Database: Synchronizes component data across machines via LAN.

Secure Data Transfer: Eliminates USB virus risks by using LAN-based file sharing.

New smart digital centering algorithm supports one-click editing for non-standard/irregular components.

Integrates advanced algorithms (Ant Colony, Clustering Analysis, AI Deep Learning) to optimize pickup/placement paths and maximize equipment utilization.

One-click import of placement coordinates via text files, Excel, or other compatible formats.

Networked Component Database: Synchronizes component data across machines via LAN.

Secure Data Transfer: Eliminates USB virus risks by using LAN-based file sharing.

| Model | Category | HW-F5 | |

| Specification | Mounting Head Module | Single Arm | |

| Track Module | Single Track | ||

| No. of Nozzles | High-Speed Mounting Head (10 nozzles) | Multi-Function Mounting Head (6 nozzles) | |

| Equipment Size | Length x Width x Height | 1380*1880*1550mm | |

| Weight | Weight | Approximately 1850KG | |

| Electrical Specification | Air Source | 0.5MPa, 200L/min | |

| Power / Wattage | AC380/420/480V, 5KW | ||

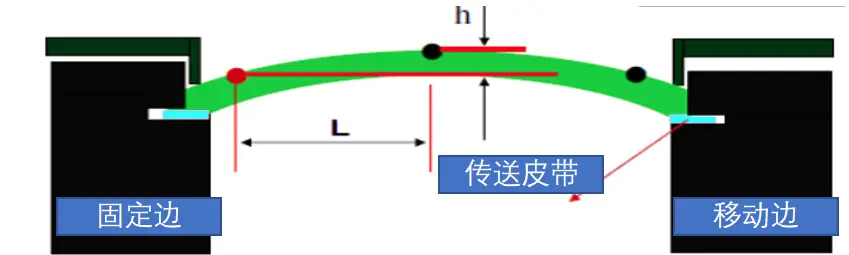

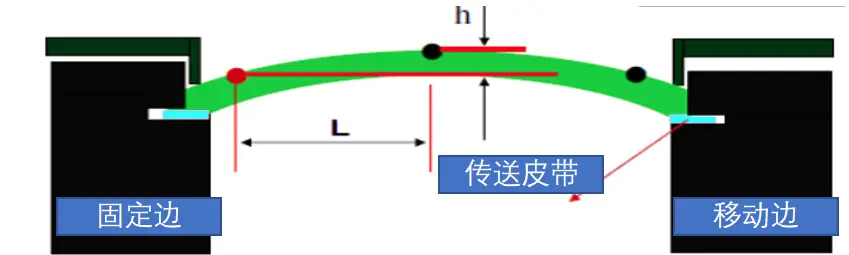

| Target Substrate | PCB Size | Single Track: Minimum 50*50mm, Maximum 510*410mm | |

| PCB Thickness | 0.5-9.0mm | ||

| PCB Fixing Method | Pneumatic Lifting Platform, Upper and Lower Clamping Plate | ||

| Mounting Function | Best Mounting Speed | 42000CPH | 18000CPH |

| Mounting Accuracy (CPK) | ±0.035mm(XYZ), CPK ≥ 1.0 | ±0.03mm(XYZ), CPK ≥ 1.0 | |

| Supported Component Range | Flying Camera: Minimum Imperial 0201, Maximum L12*W12*H6.5mm | — | |

| Fixed Camera: Minimum Imperial 0201, Maximum L40*W40*H13mm | Fixed Camera: Minimum Imperial 0201, Maximum L40*W40*H25mm | ||

| Vision System | MARK Camera Field of View | L20mm * W20mm | |

| MARK Camera Type | Area Array 500W | ||

| Component Camera Type | Flying Camera | — | |

| Fixed Camera | |||

| Feeding System | Feeder | Electric Feeder | |

| No. of Feeders | Single Side 50 Stations (8mm) Double Side 100 Stations (8mm, Optional) | ||

| Roll Material Feeder | Tape: 8/12/16/24/32/44/56mm | Tape: 8/12/16/24/32/44/56/72/88mm | |

| Tube Material Feeder | Single Vibrating Feeder Capacity: | ||

| 4-20mmx3 Tubes, 30-40mmx2 Tubes, 40-50mmx1 Tube | |||

| Tray (Optional) | — | Tray Cabinet Capacity: L323*W136*H7.5mm, 20 Trays | |

| Control Part | X-Axis | High Precision Linear Motor + Grating Scale | |

| Y-Axis | Dual Drive Linear Motor + Grating Scale, Full Closed Loop Control | ||

| Z-Axis | High Precision Linear Motor | ||

| R-Axis | High Precision Servo Motor | ||

| MES System Interface | MES Collection | Supports TCP/IP Communication Protocol | |

| MES Upload | Supports QR Code / Barcode Recognition / Binding Upload to MES | ||

Rm3A08 (4th Floor) Block D, Huashengtai Technology Park, No.36 Hangkong Road, Baoan District, Shenzhen City, China

© 2026 All Rights Reserved.