1. Definitions and Differences between SMT and PCB

1. PCB (Printed Circuit Board)

PCB is the physical substrate for electronic components, formed by etching conductive pathways on an insulating substrate. Its core function is to provide mechanical support and electrical interconnection for electronic components.

2. SMT (Surface Mount Technology)

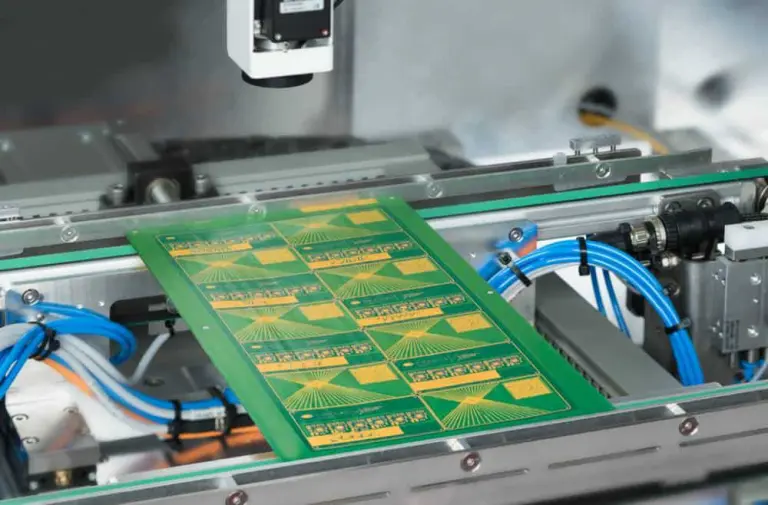

SMT is an automated assembly process that directly installs electronic components onto the surface of the PCB. The main processes include solder paste printing, component placement, and reflow soldering. Its key advantage lies in supporting the high-density integration of miniature components.

3. Essential Differences

- PCB is a static circuit board, considered a hardware carrier;

- SMT is a dynamic assembly technology, classified as a manufacturing process.

The two work in tandem: PCB provides the design foundation, while SMT enables efficient assembly.

2. Core Value of SMT in Modern PCB Assembly

1. Driving Miniaturization of Electronic Products

- Use of Miniature Components: SMT supports ultra-small components like the 01005 package (0.4mm × 0.2mm), allowing for extensive functionality integration on smartphone motherboards.

- High-Density Wiring: By employing multi-layer PCB designs, SMT allows for more complex circuit layouts within a unit area, as seen in high-end computer motherboards interconnecting CPUs and RAM.

2. Enhancing Production Efficiency and Reliability

- Fully Automated Production: High-speed pick-and-place machines can achieve tens of thousands of precision placements per hour, significantly increasing efficiency compared to traditional insertion methods.

- Process Stability: Reflow soldering produces more reliable solder joints that can endure vibrations, fulfilling automotive electronics (e.g., ECU modules) requirements in extreme environments.

3. Optimizing Electronic Performance

- High-Frequency Signal Transmission: SMT components’ short lead designs reduce parasitic inductance, allowing 5G RF modules to minimize signal loss by over 30%.

- Advantages in Heat Management: The close contact between SMT components and PCBs enhances heat dissipation, reducing temperature rises in GPU chips by 15% to 20%.

3. Typical Applications and Future Trends

1. Industry Application Examples

- Consumer Electronics: The Apple iPhone motherboard employs SMT technology for over 90% of component placements, achieving a thickness of only 1.1mm.

- Medical Devices: Portable monitors utilize SMT circuit boards with 0.5mm spacing for precise ECG signal acquisition.

2. Directions for Technological Advancement

- 3D-SMT: Stacking packages (like PoP) to further minimize size;

- Smart Flexible SMT: Catering to the mounting requirements of flexible PCBs in foldable devices.

Conclusion

SMT technology has become the core process in modern PCB manufacturing, driving products toward miniaturization, automation, and higher performance. With the development of technologies like 5G and AIoT, SMT will continue to spearhead the evolution of electronics, making it a foundational aspect of manufacturing that works in synergy with PCB design.