Tablet SMT Machine Assembly line Design Philosophy

This solution integrates the cost advantages of used equipment with the high precision requirements of key processes, suitable for the production of 10.5-inch tablet motherboards, and compatible with mixed production needs of flexible circuits (FPC) and rigid boards.

Core Equipment Configuration and Selection Strategy

| Equipment Type | Key Technical Parameters |

|---|---|

| Solder Paste Mixer | Smart viscosity control (10-200Pa·s), mixing time ≤3 minutes, compatible with lead-free solder paste |

| SMT Loader | Dual-track automatic board loading, compatible with edge-less PCBs, speed ≥800 boards/hour |

| Solder Paste Printer | Nitrogen environment printing, accuracy ±15μm, supports 0.3mm pitch BGA |

| SPI Machine | 3D laser detection, speed 40cm²/s, AI automatic optimization of printing parameters |

| Pick and Place | Accuracy ±25μm, theoretical capacity 107,370 CPH, supports 0201 components |

| Micro-component Feeding System | 0201 component dedicated, RFID smart material management, waste rate <0.3% |

| Reflow Machine | 12 temperature zones nitrogen protection, oxygen content <100ppm, supports RTS curve |

| AOI Machine | 10μm optical resolution, integrated X-Ray module (optional) |

| X-Ray Detection Machine | 5μm resolution, BGA void rate detection <3% |

| Selectives Wave Soldering | Spray coating accuracy ±0.1mm, supports THT/SMT mixed assembly |

| Precision Glue Dispensing Machine | Dispensing accuracy ±0.01ml, supports bottom filling glue & conformal coating |

| Laser Marking Machine | 20μm marking accuracy, supports QR code traceability and batch number marking |

| Docking Station | Double-track buffering capacity 80 pieces, ±1℃ temperature control, compatible with AGV docking |

| SMT Unloader | Automatic sorting + defect tracking, compatible with edge-less PCBs |

Tablet SMT Machine Production Line Layout and Logistics Optimization

1. Dual-track Flexible Production Line Layout

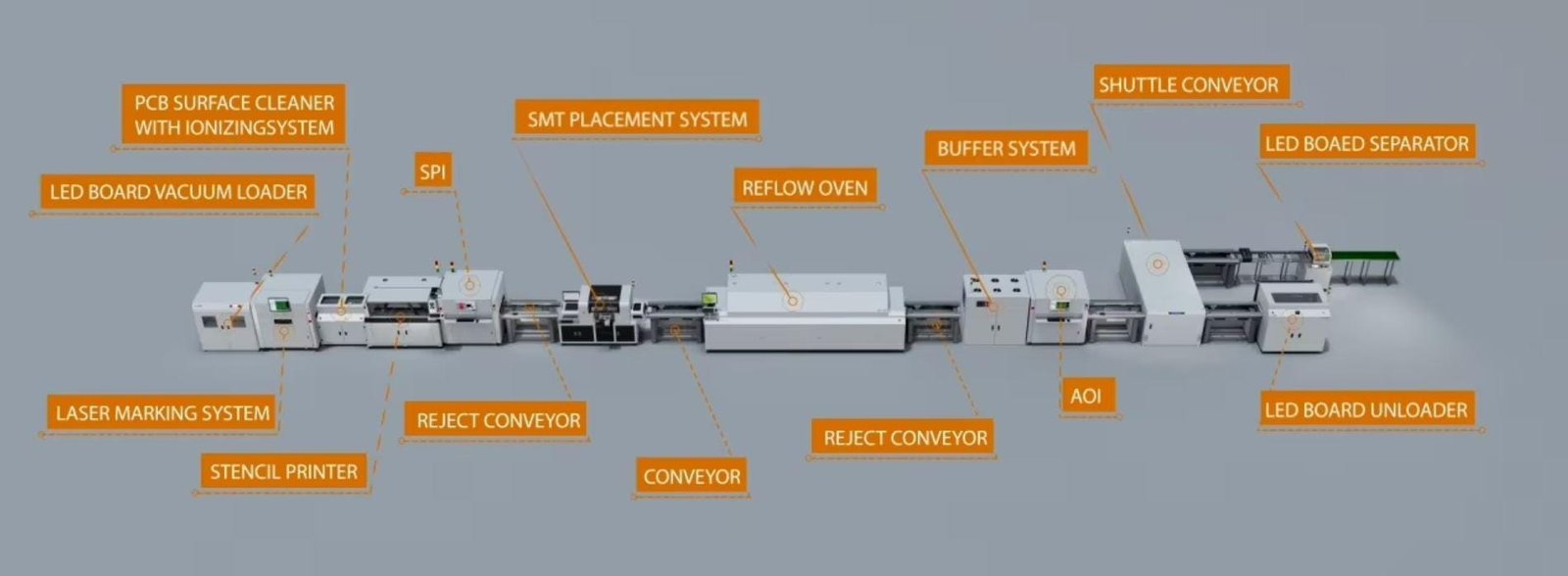

Layout Process Flow Diagram:

Loader → Printer → SPI → Connection Table → Pick and Place (NXT×3) → Reflow Soldering → AOI → X-Ray

↓

Selective Wave Soldering ← Glue Dispensing Machine ← Laser Marking ← Unloader

Design Features:

- Zone Management: Independent isolation of solder paste mixing area and printer to reduce temperature and humidity fluctuation effects.

- Micro-component Dedicated Line: CL feeders directly linked to pick and place machine, minimizing material handling distance.

- AGV Docking: Connection table reserved for AGV interface, supporting seamless integration with intelligent warehouse systems.

2. Capacity Planning Model

| Indicator | Parameter |

|---|---|

| Theoretical Mounting Speed | 107,370 CPH (NXT III×3) |

| Actual Capacity (OEE 78%) | 40,000 motherboards per shift (8 hours) |

| Changeover Time | ≤25 minutes (magnetic steel mesh + modular suction nozzle) |

| Comprehensive Throughput Rate | ≥98.5% (SPI + AOI + X-Ray triple detection) |

| Expansion Capability | Maximum capacity of 75,000 pieces per shift in dual-track mode |

Special Process Support

1. Flexible Circuit Board (FPC) Production

- Custom vacuum suction fixtures (fixture switch time ≤15 seconds)

- Printer enhanced with soft board tension control system (warpage compensation accuracy ±0.1mm)

2. Conformal Coating Process

- Glue dispensing machine integrated with selective spray coating module, supporting local conformal coating coverage

- Coating thickness control: 20-50μm adjustable (compliance with IPC-CC-830B standard)

3. Mixed Assembly Process

SMT Process: Printing → Placing → Reflow Soldering → Selective Wave Soldering (inserted components) → AOI full inspection

Tablet SMT Machine Cost Control and Value-added Services

| Strategy | Implementation Plan |

|---|---|

| Refurbished Equipment Standards | Replacement of key components (servo motors/rails), accuracy calibration to 90% of factory specifications |

| Smart Management System | Pre-installed MES system (including equipment status monitoring/process parameter traceability) |

| Environmental Compliance | Waste gas treatment module (activated carbon + catalytic combustion) in accordance with GB16297-1996 |

| Training Services | Providing a “Tablet SMT Process Debugging Handbook” + on-site engineer stationed for 5 days |

Attachments:

- 3D Layout Diagram of Production Line (including AGV Path Planning)

- Refurbished Equipment Inspection Report (including accuracy calibration data)

- Mixed Process Verification Cases (FPC + Rigid Board Same Line Production)

This solution reduces initial investment by 28% through the combination of refurbished equipment, ensuring that the throughput rate of tablet motherboards meets standards. It is recommended to prioritize the tendering for pick and place machines and SPI while simultaneously applying for lead-free process certification.