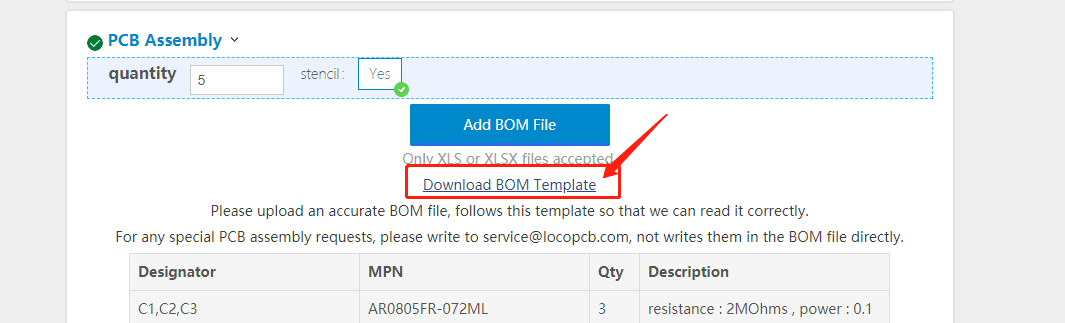

1. BOM (Bill of Materials)

Function: The BOM, or Bill of Materials, is one of the fundamental production documents in SMT processing. It lists all components used in the product along with their detailed information, including names, specifications, models, quantities, and package types. The BOM helps production personnel accurately locate and utilize components during material preparation and placement, avoiding quality issues caused by incorrect or missing parts.

Importance: The BOM is crucial in SMT processing as it forms the core foundation for material management and production planning. An accurate BOM can significantly reduce production errors, enhance efficiency, and lower costs. Incomplete or inaccurate BOM information may lead to procurement mistakes, production delays, and increased costs.

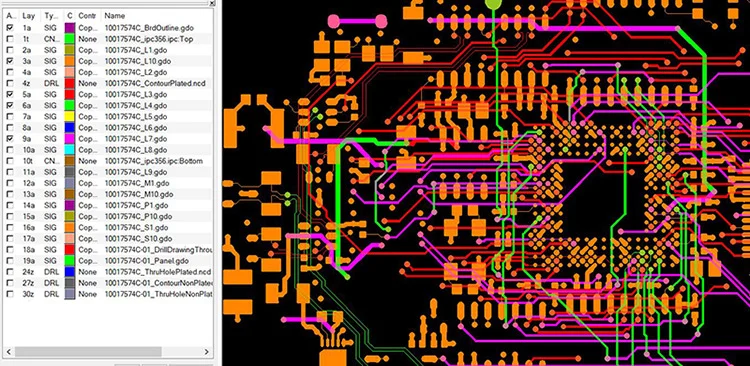

2. Gerber Files

Function: Gerber files are standard file formats used to describe PCB (Printed Circuit Board) layouts, containing detailed structural information for each layer of the circuit board, including traces, pads, and hole positions. They serve as essential data for PCB manufacturing and SMT chip processing, guiding placement machines and other equipment to ensure components are accurately placed on the circuit board.

Importance: The accuracy of Gerber files directly determines the success of the placement process. During SMT chip processing, production equipment relies on Gerber files to locate each component’s placement position and solder points. Any errors or incompleteness in the Gerber files may result in placement mistakes, subsequently affecting the circuit board’s functionality and quality.

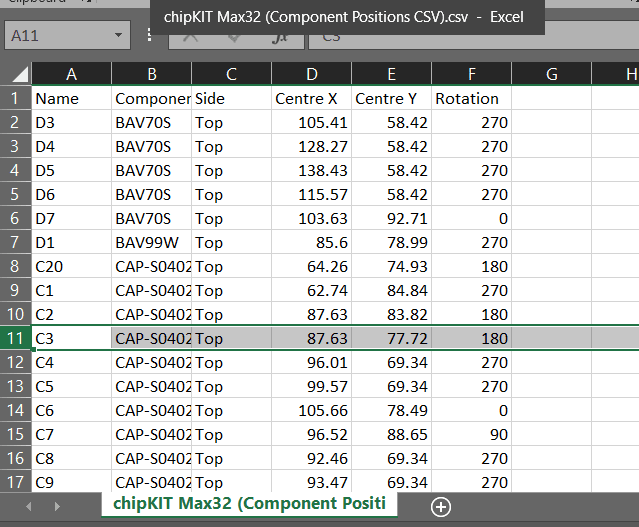

3. Pick and Place Files

Function: Pick and Place files are crucial data documents for guiding placement machines in automated component placement. They include detailed information like the X and Y coordinates, angles, and component numbers for each part, ensuring that the placement machine can accurately position each component onto the PCB at high speeds.

Importance: In modern SMT processing, placement machines are core devices for efficient production. Pick and Place files provide clear operational instructions to the machines, minimizing human intervention and enhancing accuracy and speed. Missing or erroneous pick and place files can lead to placement errors, reduced production efficiency, and possibly necessitate rework, affecting the overall production cycle.