Optimized Configuration for Tube Light Production Using HW-A8 Automatic Pick-and-Place Machine

Core Configuration and Features

- Placement Efficiency

- Maximum speed of 40,000 CPH, typical speed 15,000-30,000 CPH, suitable for mass production of tube lights.

- 8 synchronized placement heads that support parallel multi-task processing.

- Precision and Stability

- Placement accuracy of ±0.05mm, meeting the dense arrangement needs of LED tube lights.

- Granite base with 200kg counterweight design reduces vibration during high-speed operations.

- Vision System

- 8 sets of industrial-grade flying cameras achieve 360° component recognition.

- Reference mark alignment (<0.05mm) ensures precise positioning of elongated PCBs.

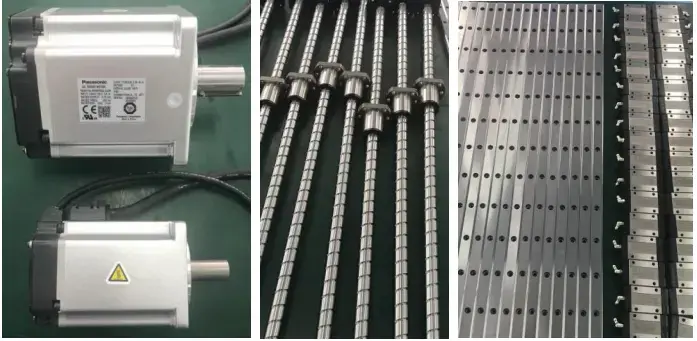

- Motion Control

- Panasonic servo drive with TBI precision ball screw, suitable for long PCB cards (maximum support of 1200mm PCB).

- Z-axis travel of 12mm, compatible with common component heights for tube lights.

Typical Application Adaptation

| Functional Module | Tube Light Production Adaptation Description |

|---|---|

| Component Compatibility | Supports 3528/5050 LEDs, driver ICs, SMD resistors, and capacitors. |

| Conveyor System | Three-stage buffering automatic conveyor belt for continuous processing of elongated PCBs. |

| Feeder Configuration | Standard with 30 x 8mm feeders to meet tube light BOM requirements. |

| Programming Control | Visual automatic programming simplifies long PCB card program settings. |

Production Scene Advantages

- Independent nozzle rotation function adapts to multi-angle placement of LED tube lights.

- Automatic vacuum detection prevents small component drop-off.

- Expanded PCB handling capability (600×400mm standard / 1200mm extended) to match different lengths of tube lights.

Technical Specifications Summary

- Power Supply: 220V/2.0kW

- Air Source Pressure: 0.55MPa

- Device Size: 1350×1300×1450mm

- Weight: 1200kg

This configuration is specifically designed for tube light production, enabling reliable placement of 15,000-30,000 components per hour on LED tube light production lines through high-speed, high-precision placement, long PCB processing capabilities, and optimized stability.