What is SMT Equipment?

SMT is the abbreviation for Surface Mount Technology. In our daily lives, various electronic products, such as digital appliances, utilize this technology for their internal circuit boards. SMT equipment, including pick-and-place machines, is used to mount electronic components onto the circuit boards, which are then soldered through a reflow oven, ultimately becoming a complete motherboard. SMT plays a significant role in today’s electronics industry. Below, we will introduce the components of SMT equipment.

What Types of SMT Equipment are There? What is an SMT Line?

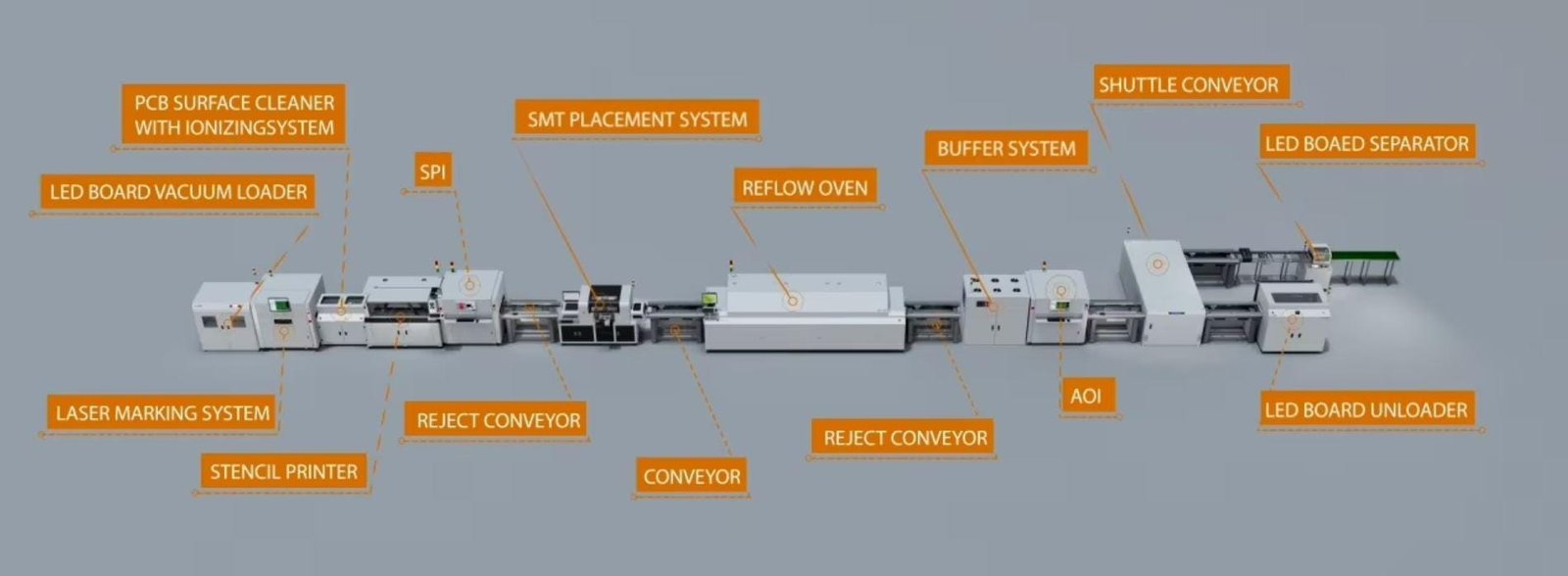

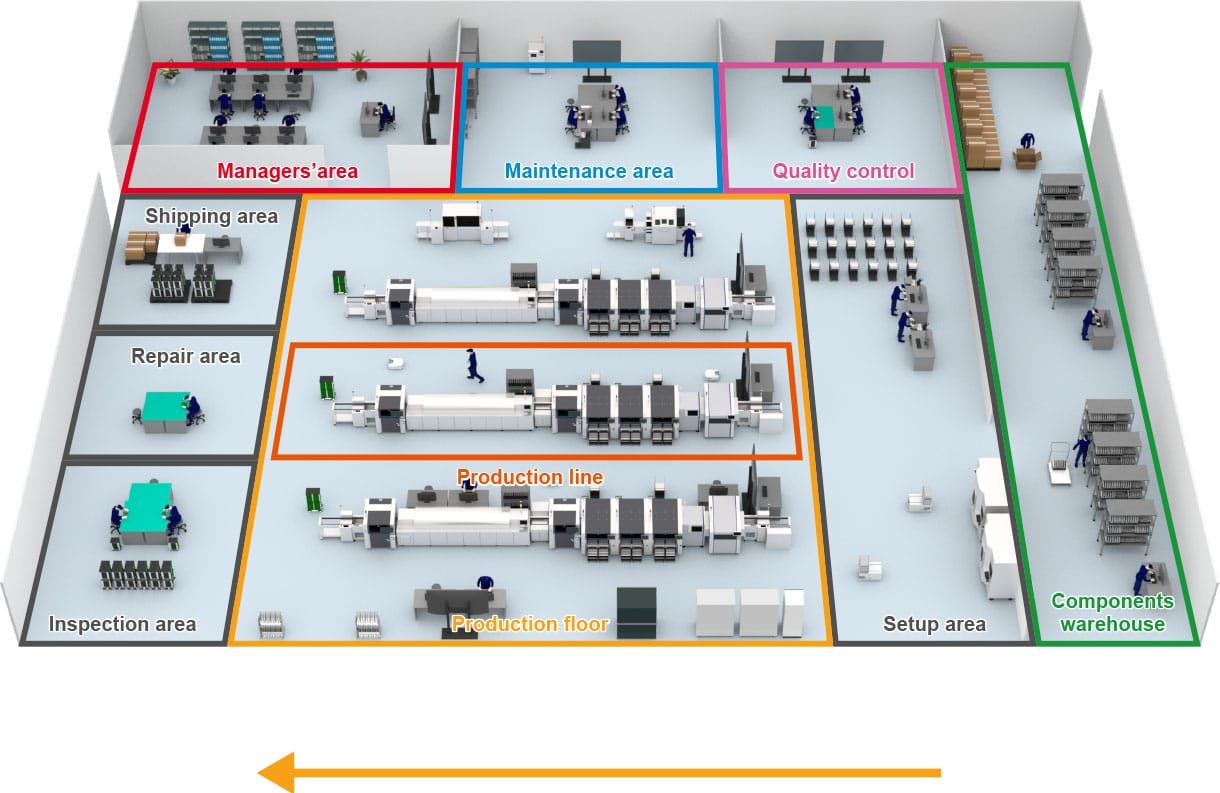

SMT equipment refers to the machines required for Surface Mount Technology. A typical complete SMT line generally includes the following equipment:

- Board Loader

- Printer

- Interface Table

- SPI

- Pick-and-Place Machine

- Inserting Machine

- Reflow Oven

- Wave Soldering

- AOI (Automated Optical Inspection)

- X-ray

- Board Unloader

The above equipment constitutes a relatively complete SMT wiring list. Different factories may add or remove relevant equipment based on their actual product needs. The essential equipment includes the printer, pick-and-place machine, and reflow oven.

Summary of SMT Equipment

SMT Production Equipment: Glue Dispensing Machine, Solder Paste Printer, Pick-and-Place Machine, Reflow Oven, Wave Soldering

SMT Inspection Equipment: SPI Solder Paste Thickness Tester, Furnace Temperature Curve Tester, AOI Optical Inspection Machine, ICT Online Tester, X-RAY Inspection System, ATE Testing System

SMT Peripheral Equipment: Solder Paste Mixer, Interface Table, Board Separator, Board Loader/Unloader, Material Handling Machine, Buffer Machine

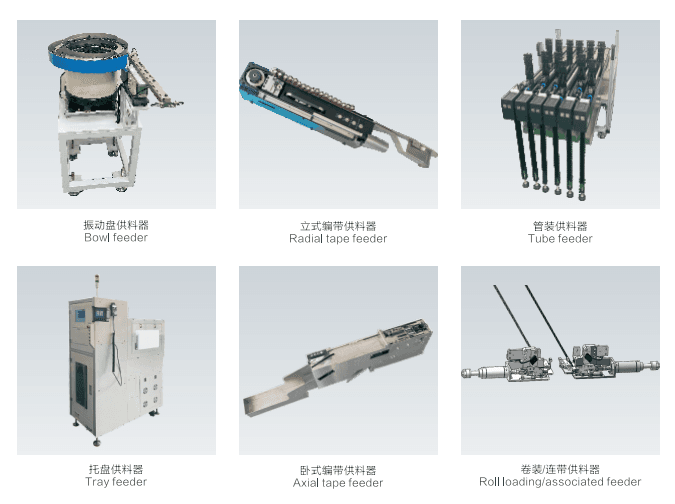

SMT Accessories: Thermocouples/Thermal Resistors, Heating Elements, Squeegees/Templates, Nozzles, Glue Dispensing Needle, Glue Dispensing Machine Barrel Accessories, Wave Soldering Nozzle, Feeders

SMT Soldering Consumables: Solder Paste/Solder Bars, SMD Adhesive, Flux

SMT Assembly Tools: Anti-static Soldering Iron, Desoldering Iron, Melting Furnace, Debris Pliers, Foam Oven

SMT Cleaning Equipment: Ultrasonic Cleaning Machine, PCBA Cleaning Machine

Anti-static Products: Anti-static Personal Protective Equipment, Anti-static Tools, Anti-static Turnover Boxes, Anti-static Packaging, Anti-static Measuring Instruments

Core Equipment and Key Functions of SMT Machines and SMT Line

Pick-and-Place Machine

- Core Position: As the heart of the SMT production line, the pick-and-place machine is responsible for accurately placing components onto PCB pads, with precision up to ±0.05mm and speeds reaching tens to hundreds of thousands of components per hour. It has the highest technical complexity, directly affecting production efficiency and yield.

- Function: It picks SMD components from trays or feeders, uses a vision system to locate them, and quickly places them on the designated pads of the PCB.

Classification:

High-Speed Pick-and-Place Machines: Designed to handle small, regular components (e.g., 0805 resistors), with speeds reaching tens of thousands of points per hour.

Multi-Functional Pick-and-Place Machines: Capable of handling complex components (e.g., BGA, QFP), with higher precision but slower speeds.

SMT Pick and Place Machine Hot style

Solder Paste Printing Machine

- It accurately prints solder paste onto PCB pads through a stencil, with the printing precision directly impacting the quality of subsequent soldering. Modern equipment uses vision alignment systems (like DEK printers), achieving precision up to ±12.5μm.

- Function: It uniformly applies solder paste to PCB pads using a stencil, providing an adhesive and conductive medium for later soldering.

- Key Parameters: Printing precision (±0.02mm), solder paste thickness detection (commonly used in conjunction with SPI equipment).

Reflow Machine

- It controls the temperature curve to melt solder paste, achieving soldering between components and the PCB. High-end devices support nitrogen protection during soldering, reducing oxidation and improving the reliability of solder joints.

- Function: It controls the melting of solder paste and forms reliable solder joints through a temperature curve (preheat, constant temperature, reflow, cooling).

- Classification: Includes hot air, infrared, steam, etc., with mainstream equipment maintaining a temperature difference of ±1°C.

AOI and X-Ray Inspection Machines

AOI: Detects solder joint defects (such as cold soldering and misalignment) through optical imaging. It checks the position, polarity, and shape of solder joints after placement.

X-Ray: Inspects for internal defects in hidden solder joints, such as BGA and QFN, ensuring the quality of high-density packaging.

SMT Production Line Auxiliary and Supporting Equipment

Solder Paste Mixer

– Ensures the uniformity of solder paste, avoiding sedimentation of particles that affects printing quality. Mixing time is usually 1-3 minutes.

SMT Loader/Unloader

– Achieves automatic loading and unloading of PCBs, supporting stacking or tray feeding, reducing manual intervention.

SPI (Solder Paste Inspection Machine)

– Inspects the thickness, area, and shape of solder paste printing to avoid defects in soldering caused by poor printing quality. The 3D inspection technology covers volume and height parameters.

Micro Component Feeding System

– Compatible with micro components like 01005 (0.4×0.2mm), requiring high-precision feeders and nozzle designs to reduce waste.

Selective Wave Soldering and Precision Dispensing Machine

– Wave Soldering: Targeted at soldering through-hole component connections; selective equipment can locally solder to save energy.

– Dispensing Machine: Used for adhesive application (such as underfill), requiring precise control of adhesive volume at the micro-level.

Laser Marking Machine and Docking Station

– Laser Marking: Marks traceability information on PCBs or components, adapting to high-speed production line demands.

– Docking Station: Connects different equipment (such as printers and pick-and-place machines) to achieve PCB buffering and synchronized transmission.

SMT Assembly Line Process

Loader → Printer → SPI → Interfacing Station → pick and place machine → Reflow → AOI → X-Ray

↓

Wave Soldering ← Dispensing Machine ← Laser Marking ← Unloader

Why is SMT Machine Important?

- Efficiency: Compared to traditional through-hole technology (THT), SMT machines enable fully automated production, reducing human intervention and are suitable for high-volume manufacturing (e.g., smartphones, computer motherboards).

- Miniaturization: Supports the mounting of smaller and lighter components to meet the compactness demands of modern electronic products.

- Reliability: Precise soldering processes reduce the defect rates of cold solder joints and short circuits, enhancing product lifespan.

For example, in smartphone motherboard production, a pick-and-place machine can complete the precise placement of hundreds of components in just one minute, while the reflow oven ensures the quality of microscopic solder joints through accurate temperature control. The comprehensive application of such machines makes SMT a mainstream technology in the electronics manufacturing industry.

Highlywin Electric Co., Limited’s Customization and Service Advantages

At Highlywin Electric Co., Limited, we understand the unique needs of our customers and offer tailored solutions for SMT machines. Our customization and service advantages include:

- Customized Solutions: We provide bespoke SMT machines designed to meet specific production requirements, ensuring optimal efficiency and effectiveness for your projects.

- Expert Support: Our team of skilled technicians offers comprehensive support to ensure that your SMT machines operate at peak performance throughout their lifespan.

- Ongoing Training: We offer continuous training and resources for your staff to enhance their operational knowledge and skills in utilizing SMT technology effectively.

- Innovative Technology Integration: We stay at the forefront of technology, integrating the latest advancements into our SMT machines to improve automation, precision, and overall performance.

- Local Development Focus: We emphasize developing domestic technology solutions that reduce reliance on imports and foster local innovation and expertise.

Conclusion

SMT machines have revolutionized the way electronic devices are manufactured, enabling the production of smaller, more reliable, and more cost-effective products. At Highlywin Electric Co., Limited, we are committed to providing innovative, customized solutions to meet the evolving demands of the electronics industry while addressing the challenges faced by manufacturers.