1. Define Product Types and Production Scale

First, it is essential to clarify the types of electronic products being processed on the production line, the complexity of the products, the components involved, and the annual production volume. Establishing a new production line or upgrading an existing one requires a comprehensive assessment. Determine the scale of the production line based on practical circumstances and calculate the specific needs for pick and place machines. If renovating or expanding, consider the machines that can still be used and whether there are plans for production expansion, ensuring the production line’s scalability.

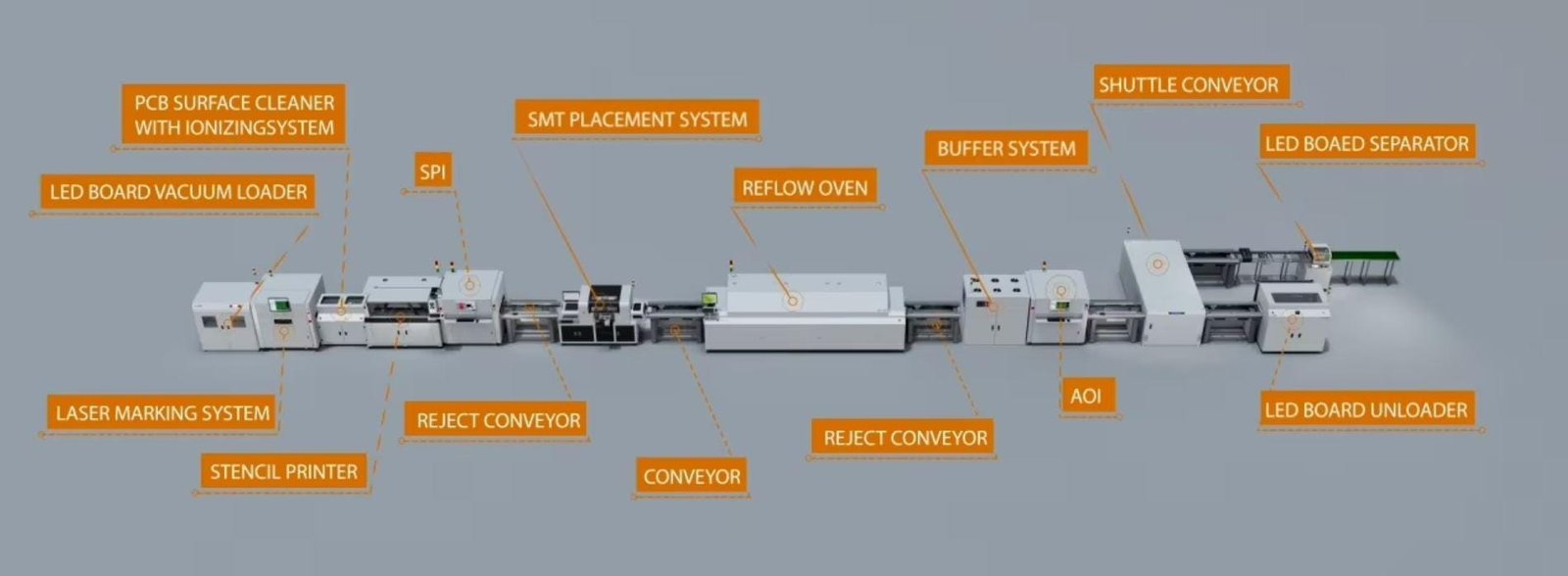

2. Determine Equipment Selection Based on Process Flow

If the products are relatively simple and utilize pure surface mount or single-sided hybrid assembly processes, choosing one type of soldering equipment (like a reflow oven or wave soldering machine) is appropriate. For more complex products with higher assembly density and numerous through-hole components requiring dual-sided hybrid assembly, both reflow and wave soldering processes should be supported by selecting both a reflow oven and a wave soldering machine. If cleaning is necessary, corresponding cleaning equipment should also be included.

3. Determine Equipment Types Based on Assembly Density

If the electronic products have high assembly density, feature multi-pin narrow pitch components, or large SMD parts, a multifunctional pick and place machine is necessary. Should one multifunctional machine be insufficient, consider adding a medium-speed pick and place machine or a high-speed machine to meet assembly demands.

4. Consider Financial Conditions

If financial resources are limited, prioritize the cost-performance ratio of the equipment. Selecting equipment that provides the best value for money is crucial during tight budget constraints.

5. Common Misconceptions in Equipment Selection

Frequently, clients inquire about which series of pick and place machines or reflow ovens are the best, or which printer is superior. In reality, the equipment needed varies depending on the products being manufactured. While it’s important to choose high-efficiency high-speed pick and place machines, ideal energy-efficient reflow ovens, and affordable yet precise stencil printers, it’s crucial for owners to carefully consider the feasibility of the equipment requested by engineers, including investment costs and returns. Engineers should understand production needs to help choose machines that offer high value for the business.