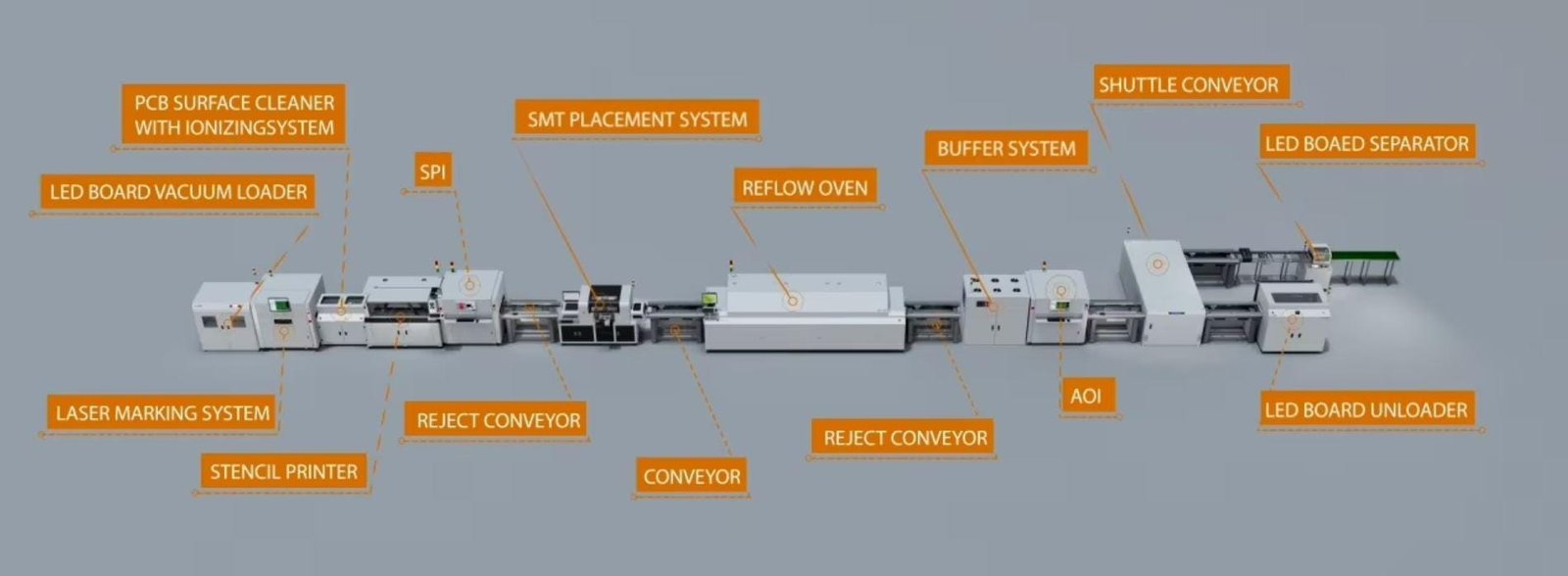

Main Equipment in SMT Production

SMT production lines include a variety of essential equipment used in the electronic manufacturing industry. Key devices include pick and place machines, solder paste printers, SPI, reflow ovens, AOI, board loaders, and conveyor systems. Each type of equipment has specific functions and purposes, which we will explore below.

1. SMT Pick and Place Machine

SMT pick and place machines are categorized into turret-type, gantry-type, and modular pick and place machines. These machines are at the center of SMT production technology, primarily used to accurately and quickly place electronic components onto designated positions on the PCB using specific methods.

2. SMT Solder Paste Printer

There are three types of solder paste printers: manual, semi-automatic, and fully automatic. The solder paste printer is the starting point of the SMT production line and plays a crucial role in the pre-assembly quality and efficiency of SMT electronic products. It applies solder paste evenly onto the corresponding pads of the PCB through a stencil, similar to the printing process used in schools for printing test sheets. As the demand for electronic product assembly increases, most companies have adopted fully automatic solder paste printers. These not only improve product quality and increase production efficiency but also save labor costs, making the process more effective.

3. SPI Inspection Equipment

SPI is typically positioned right after the SMT solder paste printer. Once the PCB with solder paste is printed, it is transmitted via a conveyor system to the SPI for inspection. This process effectively enhances the yield rate of SMT products by filtering out defective PCBs with poor solder paste application. It allows for tracing back to the root causes of defects, thus addressing the core issues and controlling future maintenance costs, ultimately aiding in increased production capacity and profitability.

4. SMT Reflow Soldering

Reflow soldering is a critical process that guarantees the quality of surface-mounted electronic products. This method utilizes convection heating to continuously heat the unsoldered PCBs, causing the soldering material to melt and cool, solidifying the components onto the PCB pads.

5. AOI Equipment

AOI (Automated Optical Inspection) equipment is typically positioned at the end of the SMT production line, following the reflow soldering process. It employs optical principles to automatically detect common defects during the soldering process. AOI is a rapidly emerging testing technology, with many manufacturers introducing their own AOI inspection equipment. During automatic detection, the machine scans the PCB using cameras, capturing images and comparing the tested solder joints with qualified parameters in a database. After image processing, it identifies defects on the PCB, displaying or marking them for technicians to rectify.